Automotive Paint Mix Tank Ultrasonic Level Sensor_________________________________________________________________

When Renault in Hubei, China needed reliable level measurement of their paint mix tanks, they turned to Flowline. Designed by Nissan and built by Dongfeng, the manufacturing plant produces 150,000 sport utility vehicles a year. During which, solid and metallic enamel paints are continuously batched, blended and pumped from the paint room to the paint line where robots apply the color and clear coats to primered car bodies. Nissan process engineers required intrinsically safe, non-contact level measurement and were concerned about the negative effects of splashing on the sensors. For this reason, Flowline suggested the use of our EchoTouch ultrasonic level sensor installed in an unusually tall riser mount. The risers eliminated the possibility of paint reaching the sensors and was acceptable in this application due to the short measurement range. Forty-four ultrasonic sensors provide reliable level data to the PLC, which in turn, controls the tank batching, mixing and pumping processes. Flowline is reliable level measurement. |

Chemical Rail Terminal Tank Radar Level Sensor_________________________________________________________________

When a Mississippi chemical distributor needed reliable level measurement of their terminal tanks, they turned to Flowline. Acids are delivered from manufacturers via railcars, and are pumped into storage tanks for customer distribution via tanker trucks. The operators monitor the filling process and level measurement is critical. But they experienced intermittence from ultrasonic sensors in hydrochloric, hydrofluoric and nitric acids due to vapor, and the resulting acoustic signal attenuation. For this reason, Flowline suggested the use of our pulse radar sensors that are unaffected by vapor, and ideal for corrosive media with our PTFE antenna shield. The pulse radar sensor provides continuous level data to the controller, which displays the remaining height available to fill, and shuts down the pump in the event of a high level alarm condition. Flowline is reliable level measurement. |

Stormwater Pump Lift Station Radar Level Sensor_________________________________________________________________

When a Houston municipality needed reliable level measurement of their storm lift stations, they turned to Flowline. Storm water flows from streets to pump stations that gather and transfer the run off to nearby treatment plants, ponds or culverts. While trash and debris are screened prior to the lift stations, sediment passes through and collects at the bottom of the sumps. There the operators had ongoing problems with pressure level sensors that would clog and require expensive confined space downhole maintenance. For this reason, Flowline suggested the use of our non-contact pulse radar sensors that provide reliable maintenance free measurement. Here the operators installed the sensor through the sump top, mounted on a metal plate for convenient access. The pulse radar sensor provides continuous level data to the SCADA, which monitors the sump and controls the two pumps. Flowline is reliable level measurement. |

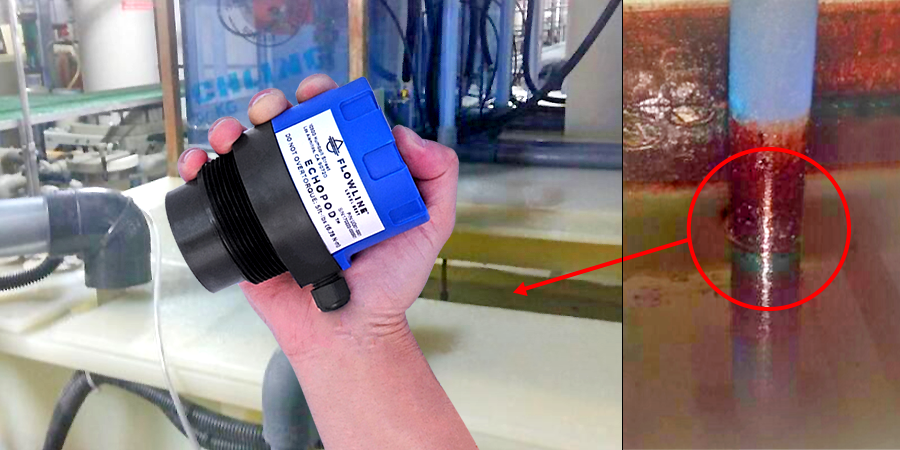

Shipyard Wastewater Storage Tank Ultrasonic Level Sensor_________________________________________________________________

When a San Diego shipyard needed reliable level measurement and control of their wastewater bulk storage tanks, they turned to Flowline. On any day, workers can be seen scraping, sanding, painting or varnishing dozens of boats that are hauled out for annual maintenance. During wash down, residual materials drain into sumps, which in turn, pump the wastewater into storage tanks, safely staged for treatment. Here the operators had ongoing failures with float and conductance level switches due to material build-up on the sensors. For this reason, Flowline suggested the use of our non-contact ultrasonic sensors that provide maintenance free level measurement of coating wastewater. Each ultrasonic sensor provides continuous level data to the controller, which monitors the tank and transfers the wastewater when full. Flowline is reliable level measurement. |

Municipal Sewer Lift Station Radar Level Sensor_________________________________________________________________

When Imperial Valley, CA needed reliable level measurement of their water treatment plant’s sewer pump lift station, they turned to Flowline. Raw sewage enters the plant through a narrow rectangular vault with two submersible pumps. Level measurement is critical, but when the vault empties, the pumps are exposed, leaving only two square feet of free measurement space. During which, the operators experienced intermittence with a different level sensor brand due to false reflections. For this reason, Flowline suggested the use of our pulse radar sensors that automatically map and disregard false signals, enabling their reliable use in limited measurement space. The pulse radar sensor provides continuous level data to the SCADA system, which in turn, monitors the vault, and controls the pumps. Flowline is reliable level measurement. |

Solar Panel Metal Finishing Tank Ultrasonic Level Sensor_________________________________________________________________

When a Malaysia solar panel manufacturer needed reliable level measurement of their plating tanks, they turned to Flowline. The highly corrosive and condensing process was a great source of level frustration to the company. Initially, the skids were delivered with float level switches that failed within a year. Then they replaced the floats with typical non-contact ultrasonic level sensors. They lasted, but performed intermittently due to condensation that attenuated their transducers acoustic signal. For this reason, Flowline suggested the use of our reflective ultrasonic sensors that are unaffected by condensation. The ultrasonic sensors provide continuous level data to the PLC, which monitors the plating tanks and periodically refills them. Flowline is reliable level measurement. |

Polymer Chemical Feed Tank Ultrasonic Level Sensor_________________________________________________________________

When a Colorado municipality needed reliable level measurement of their polymer feed tanks, they turned to Flowline. Organic flocculants are widely used in water treatment for clarification. Their polymer chains attract suspended solids to form flocs that precipitate during settling, thus leaving clear water behind. Polymer is very sticky and the operators had problems with previous conductance level sensors that required ongoing maintenance due to coating build-up. For this reason, Flowline suggested the use of our non-contact, ultrasonic liquid level sensors that are unaffected by sticky liquids. The ultrasonic sensor provides reliable level data to the SCADA, which in turn, monitors the polymer feed tanks. Flowline is reliable level measurement. |

Pharmaceutical Mixing Tank Ultrasonic Level Sensor_________________________________________________________________

When a Pennsylvania manufacturer of custom blended vaccine and biological ingredients needed reliable level measurement of their process mixing tanks, they turned to Flowline. Here, additives are batched and blended to the exact specifications of their pharmaceutical customers, and reliable non-contact level measurement is fundamental to their success. But these are challenging applications with minimal measurement space, agitation, light surface foam, and ultrasonic signal attenuating condensation. For this reason, Flowline suggested the use of our reflective ultrasonic sensors with narrow 3″ beam widths that are exclusively unaffected by condensation. The ultrasonic sensors provide continuous level data to the PLC and MES systems, which monitor, control and document production. Flowline is reliable level measurement. |

Municipal Effluent Discharge Radar Liquid Level Sensor_________________________________________________________________

When the Birdsboro, PA water treatment plant needed reliable level measurement of their effluent discharge basin, they turned to Flowline. Effluent flows continuously from the plant to the basin, where a modulating gate valve controls its further release to the Schuylkill River. In addition, two submersible pumps provide backup during peak flows or gate valve failure, and the entire process is level controlled. Hence the sensor, suspended above the basin, must perform reliably across all environmental conditions including rain, wind, snow and temperature extremes. For this reason, Flowline suggested the use of our pulse radar level sensors that are unaffected by the environment, and packaged robustly. The pulse radar sensor provides continuous level data to the local display and PLC, which in turn, monitors the basin and controls the discharge. Flowline is reliable level measurement. |

Wash System Chemical Feed Tank Ultrasonic Level Sensor_________________________________________________________________

When a New York manufacturer of commercial truck, bus, train, aircraft and equipment washing systems needed reliable level measurement of their chemical feed tanks, they turned to Flowline. While these systems vary from automated tunnels to manual spray basins, cleaning chemicals are batched and dispensed from their standard tank. Level measurement is used to make each batch and determine when a new batch is needed. The cleaning agents are coating, and their float level switches would inevitably stick, causing system failures and requiring customer maintenance. For this reason, Flowline suggested the use of our non-contact ultrasonic level sensors that are unaffected by coating or corrosive media. The ultrasonic sensor provides continuous level data to the PLC, which in turn, monitors the feed tank and controls the batch process. Flowline is reliable level measurement. |