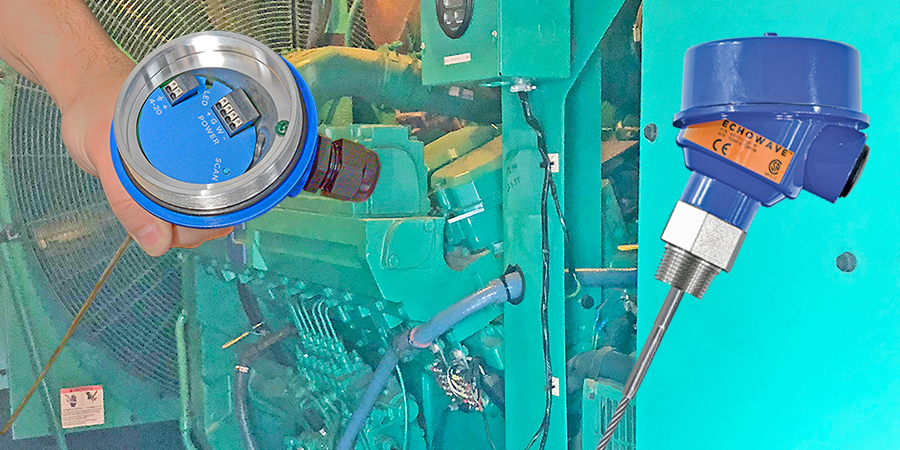

Diesel Generator Fuel Tank Guided Wave Level Sensor_________________________________________________________________

When a New Jersey equipment manufacturer needed reliable level measurement of their four backup power generators, they turned to Flowline. Each diesel generator is supplied by a 500 gallon fuel tank, and company procedures requires each to run for at least one hour a month. When audits found that the tanks were not being replenished, they determined that the float level switches were sticking due to coating, and they required periodic maintenance. The facility operators deemed that unacceptable and wanted reliable measurement. For this reason, Flowline suggested our guided wave liquid level sensors that are unaffected by coating and ideal for metal tank skid applications. The guided wave sensors provide continuous level data to the PLC, which in turn, monitors the tanks for operator replenishment. Flowline is reliable level measurement. |

Fluoride Chemical Storage Tank Radar Level Sensor_________________________________________________________________

When a Missouri water treatment plant needed reliable level measurement of their fluoride bulk storage tanks, they turned to Flowline. Fluoride is commonly injected into the nations drinking water to prevent tooth decay. In higher concentrations, fluoride is highly vaporous and corrosive. The plant had used a different brand of ultrasonic sensors with poor performance, because the thick vapor would absorb the acoustic signal, and periodically cause the sensors to lose track of the level. For this reason, Flowline suggested the use of our pulse radar level sensors that are unaffected by vapor or corrosion. The pulse radar sensors provide continuous level data to the SCADA system, which in turn, provides inventory and alarms to the operators. The 316L sensor has a PTFE antenna shield and coated aluminum enclosure for corrosive media. Flowline is reliable level measurement. |

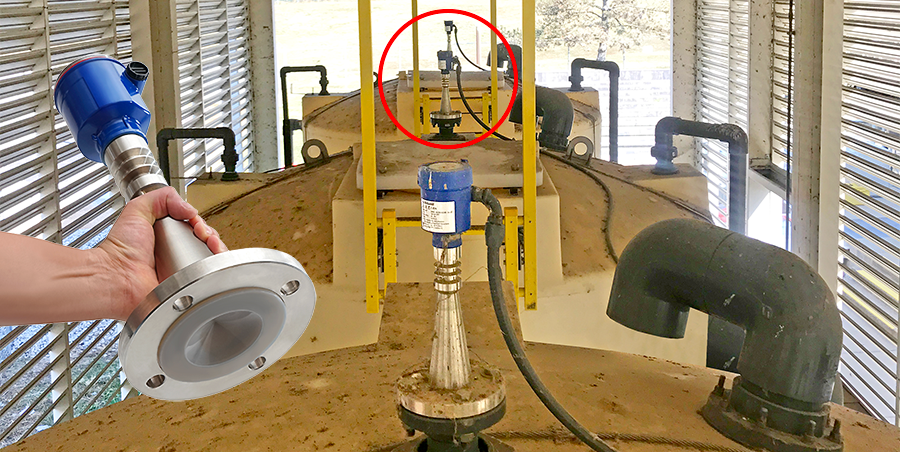

Wastewater Open Channel Guided Wave Flow Sensor_________________________________________________________________

When a New Jersey municipality needed reliable flow measurement of their open channels, they turned to Flowline. Sewage enters the water treatment plant through open channel transfer stations, where they measure and regulate the inbound flow rate. The operators had problems with their previous ultrasonic level sensors due to the presence of foam, steam and condensation, that attenuated the acoustic signal and caused the sensors to measure intermittently. For this reason, Flowline suggested the use of our guided wave level sensors that are unaffected by foam, steam, condensation or material buildup. The guided wave sensors provide continuous level data to the SCADA, which in turn, monitors and controls the flow rate. Flowline is reliable level measurement. |

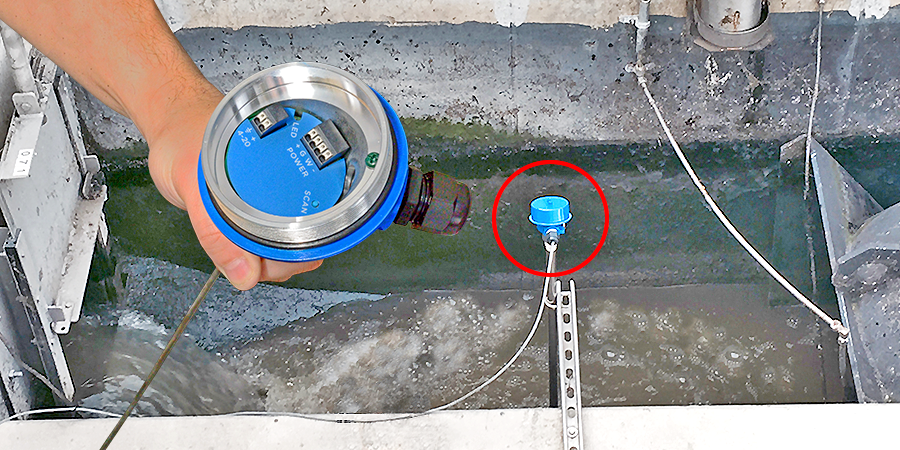

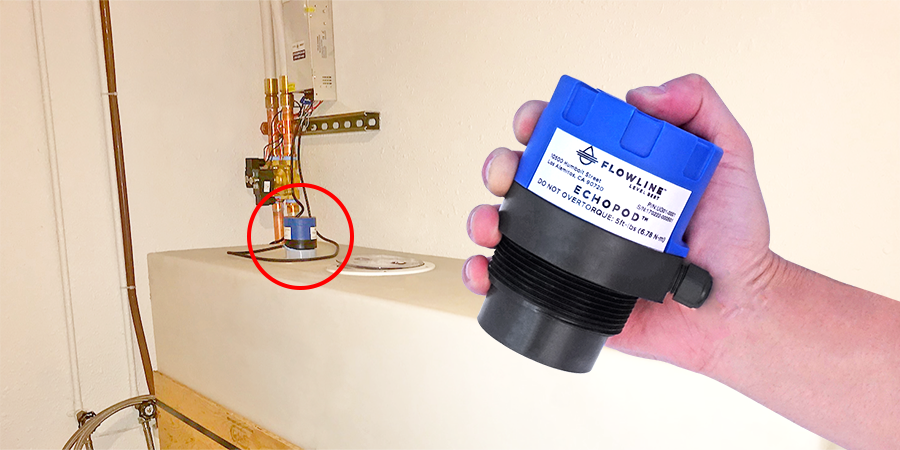

GE Turbine Generator Sump Ultrasonic Level Sensor_________________________________________________________________

When JFK International airport needed reliable level measurement of their GE LM6000 turbine generator waste sump, they turned to Flowline. The gas turbine provides power to the air traffic control system. During their annual maintenance shut down, it was found that the conductance level switches in the turbine waste sump had failed due to oily material build-up. For this reason, Flowline suggested the use of our non-contact ultrasonic level sensors that are unaffected by coating wastewater. The sensor’s four integral relays were easily configured to mimic the previous conductance level switch points, and thus required no changes in PLC programming. The ultrasonic sensor provides switch inputs to the PLC, which in turn, alerts the airport pumper truck to pick up the wastewater. Flowline is reliable level measurement. |

Stormwater Pump Station Radar Level Sensor_________________________________________________________________

When the seaside city of Dana Point, California needed reliable level measurement of their storm water pump lift stations, they turned to Flowline. This community park is adjacent to the ocean at the bottom of a steep residential street. There a lift station collects and transfers storm water run-off to the treatment plant. During periods of heavy rain, the station fills very quickly and the operators had problems with ultrasonic level sensors that were unable to track the turbulent, fast rising water. For this reason, Flowline suggested the use of our pulse radar liquid level sensors that are unaffected by turbulence, foam and fast filling or emptying. The pulse radar sensor provides continuous level data to the SCADA system, which in turn, actuates the pumps to transfer the storm water. Flowline is reliable level measurement. |

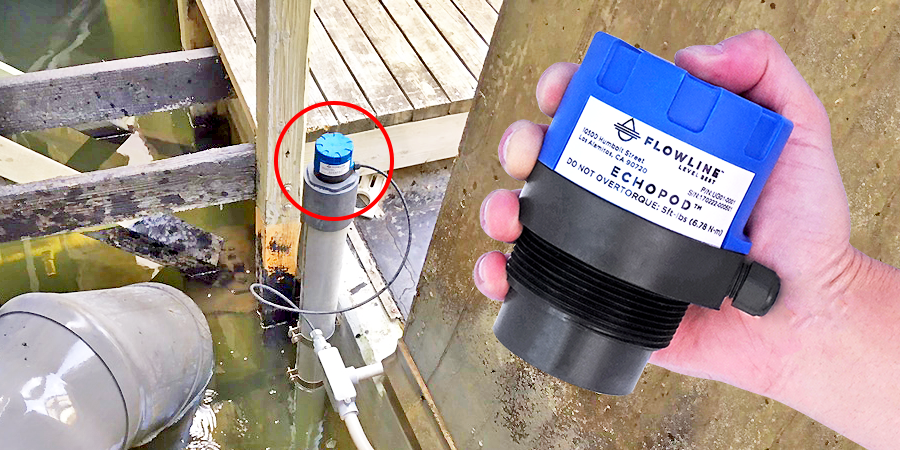

Ranch Livestock Water Tank Ultrasonic Level Sensor_________________________________________________________________

When a Montana cattle ranch needed reliable level measurement of their livestock water supply tanks, they turned to Flowline. Cattle graze the ranch and drink from eight new watering stations throughout the property. Each station has a pump house that filters, stores and dispenses fresh water to the troughs. Powder based nutritional supplements are periodically added to the water tanks and hand blended with paint mixers. But after three months of operation, the ranchers experienced several tank overflows. Upon inspection, their contractor determined that the float level switches were sticking due to material build-up. For this reason, Flowline suggested the use of our non-contact ultrasonic level sensors that are unaffected by sticky or coating type media. The integral relays were easily configured to mimic the previous float level switch points, and thus required no changes in PLC programming. The ultrasonic sensor provides switch inputs to the PLC, which in turn, controls the water tank fill valve. Flowline is reliable level measurement. |

Reliable Municipal Canal Radar Level Sensor_________________________________________________________________

When a Pennsylvania municipality needed reliable level measurement of their feed water canal, they turned to Flowline. The treatment plant supplies fresh drinking water to 375,000 homes in greater Philadelphia. Water enters the plant through a 40′ wide canal that’s fed by two reservoirs. The canal level is measured and used to control the flow rate from each reservoir. The measurement is critical and the operators had experienced problems with ultrasonic level sensors during extreme weather. For this reason, Flowline suggested the use of our pulse radar level sensors that are unaffected by environmental conditions such as rain or wind. The pulse radar sensor provides continuous level data to the SCADA system, which in turn, controls the reservoir flow rates. The local display provides convenient indication to the operators. Flowline is reliable level measurement. |

Reliable Hydrofluoric Acid Tank Radar Level Sensor_________________________________________________________________

When a Texas chemical distributor needed reliable level measurement of their hydrofluoric acid bulk storage tanks, they turned to Flowline. Extremely corrosive and vaporous, hydrofluoric acid is widely recognized as one of the most challenging liquids to measure reliably over time. Having experienced ongoing level sensor failures, plant operators asked Flowline to recommend a robust level measurement solution for their extended field evaluation. Three non-contact, stainless steel pulse radar level sensors with PTFE antenna shields were installed. After performing flawlessly for a year, the entire plant was retrofitted with reliable Flowline level sensors. The pulse radar sensors provide continuous level data to the wireless telemetry units, which in turn, remotely monitor the tank levels for replenishment. Flowline is reliable level measurement. |

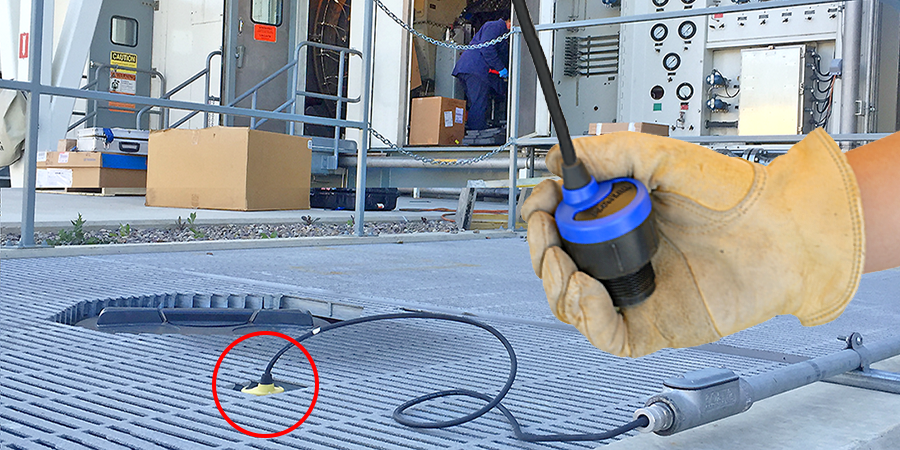

Municipal Sewer Pump Station Radar Level Sensor_________________________________________________________________

When a Wisconsin municipality needed reliable level measurement of their most challenging sewer lift stations, they turned to Flowline. Some of their pump stations have in-flow pipes located near the bottom of the sumps that pour into shallow vaults. Where so, the operators maintain the level inside the vault space to eliminate the chance of sewage back flow. But the vaults are so small, they quickly fill with grease and debris that clogs the float level switches, and requires weekly maintenance. For this reason, Flowline suggested the use of our pulse radar sensors that are unaffected by sewer grease, debris or foam, and are intrinsically safe for environments with methane gas. The pulse radar sensor provides reliable level data to the SCADA, which in turn, controls the pumping process and alarms. The sensor’s level indicator is installed above grade in the control panel. Flowline is reliable level measurement. |

Reliable Cooling Tower Basin Ultrasonic Level Sensor_________________________________________________________________

When the University of Kansas Medical Center needed reliable level measurement of their cooling towers, they turned to Flowline. Climate control is critical to the healthcare, research and education provided at the facility, and the maintenance staff identified sump level control as their number one reliability problem. Tired of replacing corroding or sticking level switches, they installed non-contact ultrasonic level sensors. But they experienced intermittent performance, as condensation would build up on the transducer face and attenuate the acoustic measurement signal. For this reason, Flowline suggested the use of our patent pending reflective ultrasonic liquid level sensors that work in condensation. The ultrasonic sensor provides continuous level data to the SCADA, which in turn, monitors and periodically refills the sump. Flowline is reliable level measurement. |