Reliable And Easy To Use Radar Liquid Level Sensor_________________________________________________________________

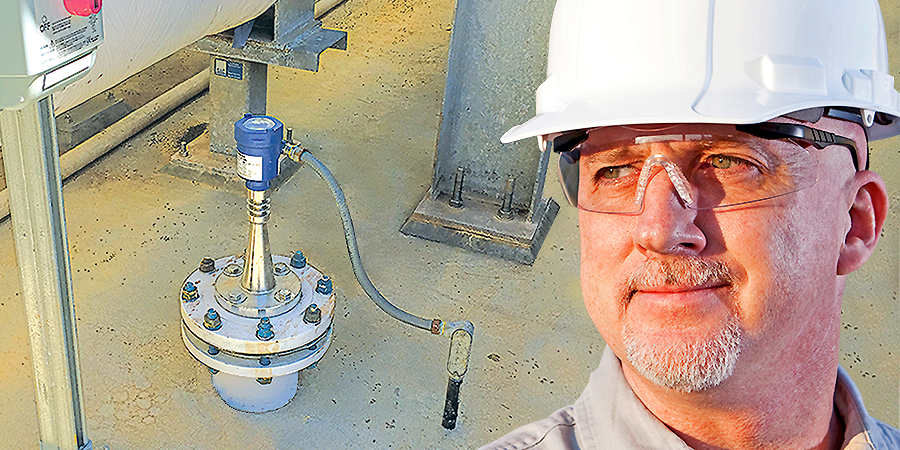

When a California municipality needed reliable, easy to use level measurement solutions for their water treatment plant, they turned to Flowline. Six years ago, the facility converted from ultrasonic to radar sensors in their challenging applications to improve measurement reliability. While reliability increased, so did their cost of sensor configuration which often involved expensive factory support, when they could get it. For this reason, Flowline suggested that they try our pulse radars sensors which are both reliable and easy to use. After lengthy evaluation, the plant switched to Flowline radar sensors, and now they do configuration themselves. Each pulse radar sensor provides continuous level data to the SCADA, which in turn, controls the water treatment processes. Flowline is reliable level measurement.

|

Reliable Batch Mix Tank Ultrasonic Level Sensor_________________________________________________________________

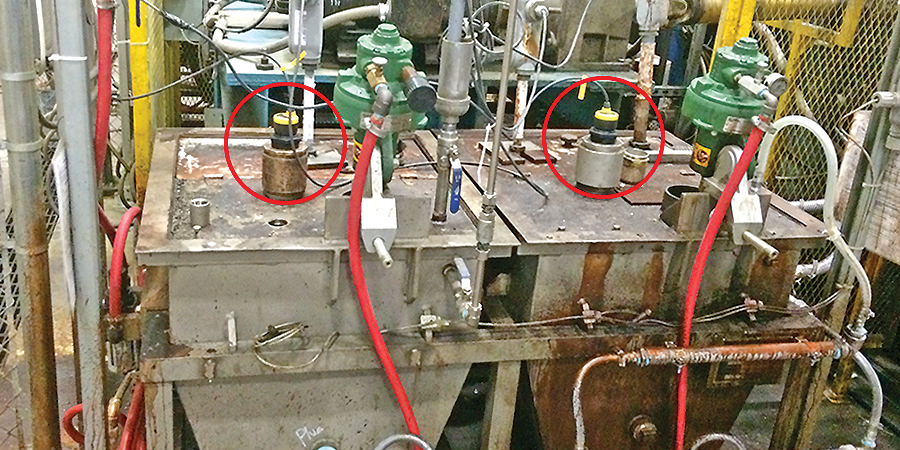

When a Utah manufacturer needed reliable level measurement of their batch mix tanks, they turned to Flowline. The company blends corrosive etching solutions and level height is used to determine the amount of each ingredient added to a batch. The solutions are mildly corrosive, somewhat viscous and they foam during mixing. The operators had experienced ongoing maintenance problems with their previous float level sensors due to material build-up. For this reason, Flowline suggested the use of our non-contact, ultrasonic liquid level sensors that are unaffected by corrosive or coating media. The sensors were installed in a stand-pipe to isolate the measurement from surface foam. Each ultrasonic sensor provides continuous level data to the PLC, which in turn, controls the batch, blending and dispensing process. Flowline is reliable level measurement.

|

Foaming Wastewater Tank Radar Level Sensor_________________________________________________________________

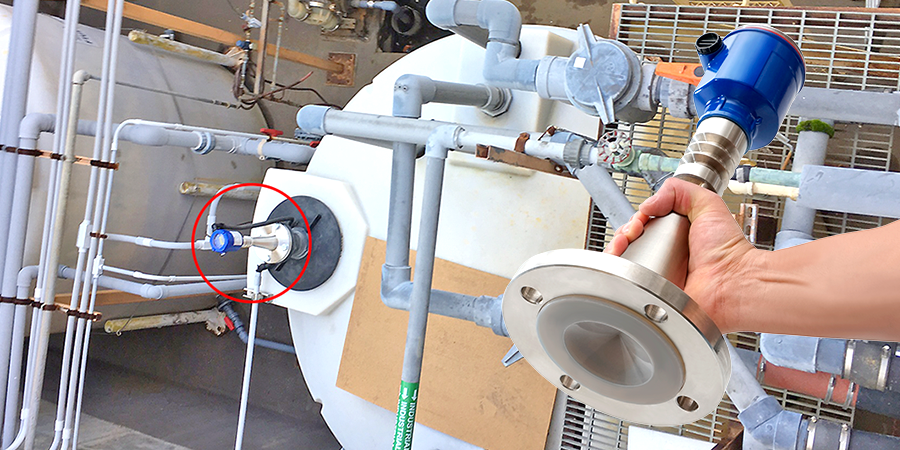

When a Southern California aerospace company needed reliable level measurement of their wastewater bulk storage tanks, they turned to Flowline. As the wastewater is pumped to the treatment system, the agitation generates foam, and the operators had experienced problems with their ultrasonic sensors due to acoustic signal absorption. For this reason, Flowline suggested the use of our pulse radar liquid level sensors that are unaffected by surface foam. The pulse radar sensor provides reliable level data to the PLC, which in turn, monitors the bulk storage tanks, and transfers the wastewater into treatment. Flowline is reliable level measurement.

|

Lacquer And Varnish Tank Radar Level Sensor_________________________________________________________________

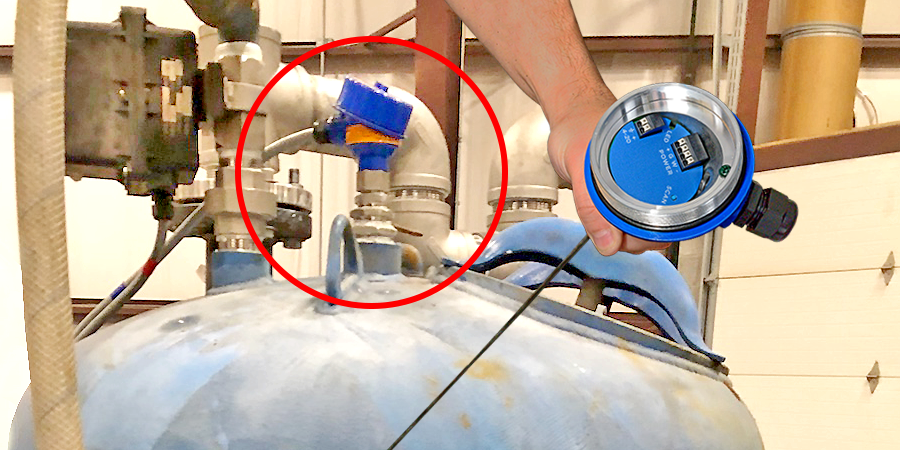

When a Pennsylvania manufacturer of food and beverage packaging needed reliable level measurement of their bulk storage tanks, they turned to Flowline. Lacquer and varnish coatings are widely used to seal printed labels and packaging. These finishes are very sticky and will adhere to anything they contact. In addition, they’re highly vaporous, which caused their previous ultrasonic level sensors to perform erratically. For this reason, Flowline suggested the use of our non-contact, pulse radar liquid level sensors that are unaffected by vapor. The pulse radar sensors provide reliable level data to the PLC, which in turn, monitors their storage tank inventories for replenishment. Flowline is reliable level measurement.

|

Municipal Chemical Feed Tank Ultrasonic Level Sensor_________________________________________________________________

When a California water district needed reliable level measurement of their pump station chemical feed tanks, they turned to Flowline. The sewage treatment process begins in six remote lift stations that directly supply their plant. In which, they inject sodium chlorite for disinfection and hydrochloric acid for pH neutralization. Highly corrosive, the operators had experienced numerous failures with their previous float level switches. For this reason, Flowline suggested the use of our corrosion resistant ultrasonic level sensors that measure chemical drums and totes reliably. The ultrasonic sensors provide reliable level data to the SCADA, which in turn, monitors their chemical inventories and alerts staff when they need more product. Flowline is reliable level measurement.

|

Power Plant Waste Sump Radar Level Sensor_________________________________________________________________

When a California power plant needed reliable level measurement of their wastewater pump lift stations, they turned to Flowline. The plant recently upgraded their waste treatment systems with the goal of recycling 100% of their recovered process water. An investigation into several lift station overflows determined that their previous float level switches periodically failed due to entanglement, caused by turbulence and grease material build-up. For this reason, Flowline suggested the use of our non-contact pulse radar liquid level sensors that are unaffected by sump turbulence, grease or foam. The pulse radar sensor provides reliable level data to the SCADA, which in turn, monitors the sump level and actuates the transfer pumps. Flowline is reliable level measurement.

|

Steam & Foam Wastewater Guided Wave Level Sensor_________________________________________________________________

When a Wisconsin bacon processing plant needed reliable level measurement of their waste recovery tank, they turned to Flowline. Steaming wastewater enters the tank with foaming grease, chunks of fat and chemical that the process engineer calls the perfect storm. Over the years, many different level sensors have been evaluated in this application, but all failed. For this reason, Flowline suggested the use of our guided wave liquid level sensors that are unaffected by steam, foam, coating or diluted corrosive media. The guided wave sensor provides reliable level data to the VFD, which in turn, monitors the tank level, and continuously transfers the wastewater to the next treatment stage. Flowline is reliable level measurement.

|

Hot Water Storage Tank Ultrasonic Level Sensor_________________________________________________________________

When a Michigan manufacturer of air solenoid valves needed reliable level measurement of their water storage tanks, they turned to Flowline. The company plates or paints their valve components and hot water is supplied to both processes through insulated bulk tanks. Heated to 100º F., the storage tanks are dripping with condensation that caused their previous ultrasonic level sensors to function erratically due to acoustic signal attenuation. For this reason, Flowline suggested the use of our reflective ultrasonic liquid level sensors that work in condensation. The ultrasonic sensors provide reliable level data to the controller, which in turn, monitors the water inventory and periodically refills the tank from the boiler. Flowline is reliable level measurement.

|

Boiler Condensate Recovery Tank Guided Wave Level Sensor_________________________________________________________________

When a Pennsylvania equipment rental company needed reliable level measurement of their boiler condensate recovery systems, they turned to Flowline. The systems capture and return hot water condensed from steam to the customers boiler. Over several months of use, some clients complained that the systems functioned erratically. Failure analysis determined that the root cause was scaling that made their float level switches stick, which required field maintenance. For this reason, Flowline suggested the use of our guided wave level sensors that are unaffected by scaling build up and ideal for high temperature and pressure applications in metal tanks. The guided wave sensor provides reliable level data to the controller, which in turn, monitors the water level and transfers it to the boiler. Flowline is reliable level measurement.

|

Reliable Sewer Pump Station Radar Level Sensor_________________________________________________________________

When a Southern California municipality needed reliable level measurement of their sewer pump lift stations, they turned to Flowline. The operators had problems with their submersible bubbler and pressure level sensors. Both clogged over time and required proactive maintenance to remove sludge build up from their sensing elements. For this reason, Flowline suggested the use of our non-contact pulse radar level sensors, that are easily installed above the liquid level for reliable, maintenance free performance. The pulse radar sensor provides reliable level data to the SCADA system, which in turn, monitors the sump level, and transfers the wastewater to the plant. Flowline is reliable level measurement.

|