Wastewater Neutralization Tank Ultrasonic Level Sensor_________________________________________________________________

When a US piping systems manufacturer needed reliable level measurement of their wastewater pH neutralization tanks, they turned to Flowline. The company produces HDPE products for stormwater applications. Pipes are water cooled as they pass extrusion, and the residual hot wastewater collects in mix tanks for neutralization with phosphoric acid. There the operators had problems with a different ultrasonic level sensor brand due to condensation, and the resulting acoustic signal attenuation. For this reason, Flowline suggested the use of our reflective ultrasonic sensors that are unaffected by condensation. The ultrasonic sensor provides continuous level data to the PLC, which in turn, monitors the tanks, and controls the neutralization. Flowline is reliable level measurement. |

Foaming Wastewater Process Radar Level Sensor_________________________________________________________________

When an Ohio truck chassis manufacturer needed reliable level measurement of their phosphoric acid dip and rinse baths, they turned to Flowline. Prior to paint, each chassis is soaked, cleaned and stripped in a 100º F. solution of 35% acid with 10% water based solvent. Acidic steam rises from the baths, condensing and corroding nearby surfaces and depositing phosphorous crystals. Operators tried several ultrasonic level sensor brands, but each became intermittent and failed within 7-10 days. Inspection revealed that acoustic signal attenuating condensation had formed on their transducers and crystalized. For this reason, Flowline suggested the use of our reflective ultrasonic sensors that are unaffected by condensation. The ultrasonic sensors provide continuous level data to the PLC, which in turn, monitors and refills the baths. Flowline is reliable level measurement. |

Automotive Plating Bath Ultrasonic Level Sensor_________________________________________________________________

When a US energy distributor needed reliable level measurement of their diesel dispensing systems, they turned to Flowline. The company supplies onsite fuel to oil field rigs, generators and trucks through their automated trailers. Each customer tank receives a level sensor and supply hose connected to a trailer. When a tanker arrives, it connects to the trailer, the trailer automatically fills each tank and sends the gallons dispensed to the company for customer billing. Engineers selected our guided wave level sensors because of their accuracy, reliability, robust metal packaging and cost effectiveness. Prior to installation and use, a technician configures and tests each system in the shown close loop test tank. The guided wave sensors provide continuous level data to the SCADA, which in turn, monitors the tanks and controls the dispensing. Flowline is reliable level measurement. |

Diesel Fuel Dispensing Tank Guided Wave Level Sensor_________________________________________________________________

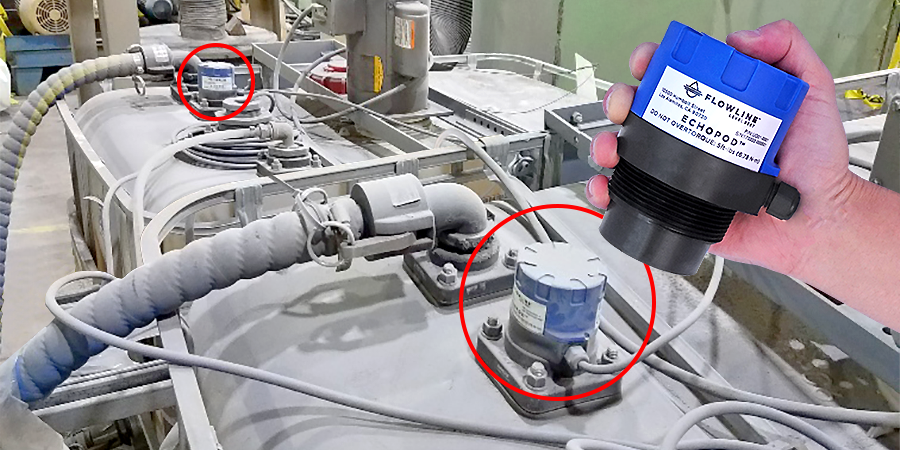

When a US steel company needed reliable level measurement of their wastewater process tanks, they turned to Flowline. Water is used throughout manufacturing and their waste streams are filled with residual particulates, oil, chemicals and dirt. To avoid contacting the media, the operators had previously installed ultrasonic level sensors. They worked well with the exception of foaming waste streams where they had intermittent measurement due to acoustic signal absorption. For this reason, Flowline suggested the use of our pulse radar level sensors that are unaffected by foam. The pulse radar sensors provide continuous level data to the PLC, which in turn, monitors the tanks, and controls the treatment process. Flowline is reliable level measurement. |

Spent Acid Wastewater Tank Ultrasonic Level Sensor_________________________________________________________________

When a Midwest bumper manufacturer needed reliable level measurement of their acid storage and wastewater treatment tanks, they turned to Flowline. The company uses hydrochloric and sulfuric acids to pickle or etch metallic bumper parts prior to chrome plating. The spent HCL, H2S04 and H2CR04 streams are periodically transferred to an outdoor wastewater storage tank. Here the operators had problems with a different ultrasonic level sensor brand due to temperature fluctuations, the resulting condensation, and a thin bubble layer that attenuated their acoustic signal. For this reason, Flowline suggested the use of our reflective ultrasonic sensor that’s unaffected by condensation with a powerful 3″ transducer. The ultrasonic sensor provides continuous level data to the PLC, which in turn, monitors the tank and controls the process. Flowline is reliable level measurement. |

Glycol Dehydration Skid Tank Guided Wave Level Sensor_________________________________________________________________

When a US energy company needed reliable level measurement of their glycol dehydration skids, they turned to Flowline. When natural gas exits a well, it typically contains water that can damage downstream processes and equipment. To combat this, a glycol dehydration system is used to absorb and separate the water from the gas stream. Level measurement of the glycol supply and condenser tanks is critical, and the company remotely monitors these skids. The operator used a different guided wave level sensor brand, and was dissatisfied with its high cost and programming complexity. For this reason, Flowline suggested the use of our guided wave sensor that saved them considerable money in product, and time in setup with our free WebCal configuration software. The guided wave sensors provide continuous level data to the SCADA, which in turn, monitors the tanks and controls the process. Flowline is reliable level measurement. |

Resin Powder Silo Radar Level Sensor_________________________________________________________________

When a Southeast specialty plastics manufacturer needed reliable level measurement of their powder silo’s, they turned to Flowline. The plant formulates and manufactures plastic pellets for use in medical and biopharmaceutical products. During which, colored resin powder is blended with other resins to achieve the specified color. Powder inventory management is critical to production, and the company had ongoing failures of mechanical paddle and rotary type level switches. For this reason, Flowline suggested the use of our radar level sensors that provide reliable, non-contact measurement of powder in dusty applications. The pulse radar sensors provide continuous level data to the PLC, which in turn, monitors the silos and alarms for powder replenishment. Flowline is reliable level measurement. |

Copper Metal Finishing Bath Ultrasonic Level Sensor_________________________________________________________________

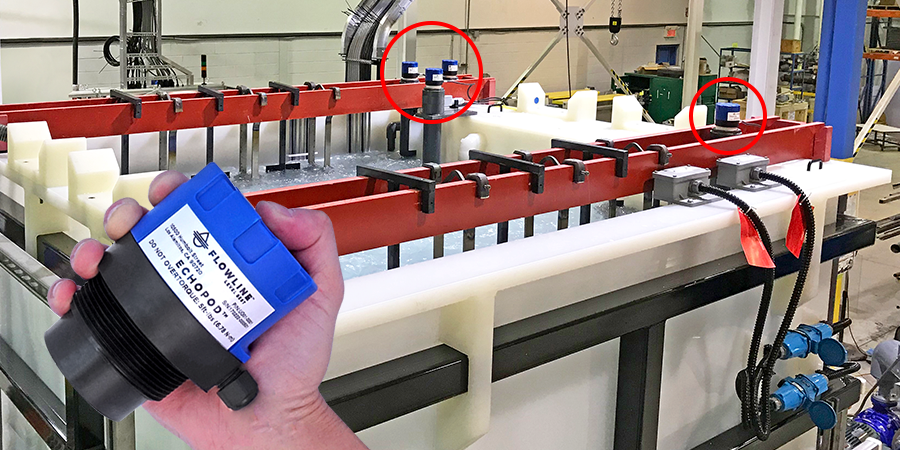

When a North American metal finishing equipment manufacturer needed reliable level measurement of their plating baths, they turned to Flowline. This system has four vessels including the primary, two for plating and one for pump recirculation that each require level control. Tired of ongoing conductance level switch failures, the engineering team wanted non-contact measurement, but found that typical ultrasonic level sensors were equally unreliable due to the acoustic signal attenuating effects of condensation and foam. For this reason, Flowline suggested the use of our proprietary reflective ultrasonic level sensors that are unaffected by condensation, installed in a stand-pipe. The ultrasonic sensors provide continuous level data to the PLC, which in turn, monitors the baths and controls the process. Flowline is reliable level measurement. |

Hydraulic Fluid Oil Tank Ultrasonic Level Sensor_________________________________________________________________

When a Wisconsin steel company needed reliable level measurement of their hydraulic fluid tanks, they turned to Flowline. Thirty-two hydraulic pumps pull the rolled aluminum sheet through their hot-dip galvanization process, and the supply of hydraulic fluid to each pump is critical to avoiding production downtime and/or pump damage. Plant operators were dissatisfied with a different ultrasonic level sensor brand which has an 8″ dead band, that prevented them from filling the shallow reservoirs to capacity. Filled manually, this increased the tasks frequency and labor cost. For this reason, Flowline suggested the use of our EchoPod ultrasonic sensors that are designed for small tanks with dead bands as little as 2″. The ultrasonic sensors provide continuous level data to the PLC, which in turn, monitors the tanks, and alarms for replenishment. Flowline is reliable level measurement. |

Wood Chip And Pellet Silo Radar Level Sensor_________________________________________________________________

When a Gulf Coast wood processing plant needed reliable level measurement of their chip and pellet silos, they turned to Flowline. Harvested logs are stripped, chipped, milled, blended with vegetable oil, and pressed and dried into pellets, prior to rail shipment to power plants, where the pellets are combined with coal and burned. These silos are tall, dusty applications with frequent fill and empty cycles, and their continuous process demands measurement reliability. Further, the operators wanted to directly replace a competitive yellow brand with a gimbal flange installation. For this reason, Flowline suggested the use of our solids radar level sensors that work with chips, pellets or powders in dust with varying angles of repose. The radar sensor provides continuous level data to the PLC, which in turn, monitors the silos and controls the process. Flowline is reliable level measurement. |