|

|

|

|

|

|

|

Orbit® ACS (SI100 & SI200)

Solartron Metrology, the world leader in linear measurement innovation, introduces two new Orbit® 3 based systems for easy, low cost connections into PLCs and process control systems. The SI100 is a single channel, stand alone system, while the SI200 also connects to an Orbit®3 probe for a two channel reading.

|

|

|

|

|

SI100 & SI200

Intergral Readout with colour LCD Display Intergral Readout with colour LCD Display

Modbus output (RTU or ASCII) over RS485 or RS232 Modbus output (RTU or ASCII) over RS485 or RS232

24V DC Power Supply 24V DC Power Supply

|

|

|

|

|

|

|

|

|

Orbit® ACS Support

|

Solartron Metrology, the world leader in digital gauging probe innovation introduces the SI100 and SI200. The SI100 and SI200 naturally come with all of the standard metrology functions such as zero, preset and TIR. The units can also be programmed to provide limit information.

|

|

|

|

|

|

|

|

Orbit®ACS FAQ's

|

Q.

|

What is Orbit® ACS?

|

|

A. |

Orbit® ACS , which stands for Automation and Control Systems, is a new line of Solartron products designed for quick, easy interfaces into automation and PLC systems. A user can quickly set up the digital probe and process limits on the integral keypad and screen, and then output to a PLC via Modbus or ASCII communication. Seven lines of I/O are also available. The first product is the SI 100 which comes with a probe and is a simple one channel stand-alone unit for quick measurement and PLC output. The SI 200 comes with a probe, integral screen, and PLC output, but can also connect to one Orbit® digital probe via T-con for a two channel system.

|

|

Q. |

Will the SI 100 & SI 200 connect with all Solartron Sensors?

|

|

A. |

Yes. When the SI 100/200 are initially released, they will be available with just standard digital probes, block gauges, ect.

|

|

Q. |

Will a probe connected to an SI 100 or SI 200 have the same accuracy as a standard Orbit® probe?

|

|

A. |

Yes. The probe will carry the same accuracy, repeatability, and resolution as an Orbit® probe. A probe with an SI 100 or SI 200 module is calibrated the same way as an Orbit® probe in the Solartron factory. The probes will also be IP65 rated, with 2 meters of cable.

|

|

Q. |

Do you need an Orbit® power supply interface module (PSIM) for the SI 100 or SI 200? |

|

A. |

No. The modules can be powered by a 24V DC supply through the pins on the back of the module. If the customer does not have their own DC power supply, Solartron will offer a power pack as an option.

|

|

Q. |

Why can’t the SI100 connect onto the Orbit® network?

|

|

A. |

The SI 100 was built to be a stand alone unit that could connect one measurement channel straight into a PLC. For single or dual channel applications, customers either want the direct PLC interface or the Orbit® network interface, but not both.

|

|

Q. |

Can the SI200 connect with more than one Orbit® module? |

|

A. |

No. The SI 200 is built strictly as a two-channel stand-alone system. Like the SI 100, it will not plug into a “stack” of Orbit® modules.

|

|

Q. |

Can I connect any type of probe to the SI200?

|

|

A. |

Yes. As long as it is a digital probe, it will connect to the SI 200.

|

|

Q. |

Can I connect an AIM or EIM module to the SI200?

|

|

A. |

Not yet, but that will be available in the future

|

|

Q. |

Can I program or master the SI 100 or SI 200 via the PLC? |

|

A. |

Yes. Items such as limits can be programmed from the PLC via the Modbus or RS232 format.

|

|

Q. |

Can the SI 100 or SI 200 be used to replace an obsolete Solartron readout?

|

|

A. |

Yes. The SI100 and SI200 will have the SI 1500, SI 3500, DR600/700, and C55 type outputs available.

|

|

Q. |

There is a mini-USB port on the back of the SI 100 and SI 200. What is the purpose of that?

|

|

A. |

The mini-USB port is there so any upgrades to firmware can be done in the field via a laptop and Solartron software. It will also be used on future Orbit® ACS products to program the module.

|

|

Q. |

Can I output data via the mini-USB port?

|

|

A. |

No. The port is not powered in such a way where it can output data.

|

|

Q. |

Will the SI 100 or SI 200 have password protection?

|

|

A. |

Yes. That feature is available

|

|

Q. |

What will the Solartron descriptions be for these Orbit® ACS probes?

|

|

A. |

Solartron descriptions will start out with a SI100 or SI 200 prefix. So, for the SI 100: SI100 (Transducer type)/(Stroke length) / (Spring or Pneumatic).

So, a 5 mm spring probe would be SI100P/5/S. A 10mm Jet Probe would be SI100J/10/P. A 2mm Pneumatic flexure would be SI100U/2/P. The SI 200 will be the same way: SI200(Transducer type)/(Stroke length)/(Spring or Pneumatic).

So, a 2mm pneumatic probe would be SI200P/2/P. A 10mm Block Gauge would be SI200K/S.

|

|

Q. |

How will part numbers be created?

|

|

A. |

To keep the part numbering system simple, the same base part number as a digital Orbit® probe will be used, but a suffix of “S100” or “S200” will be added at the end.

For example, the part number for a DP/2/S is 971100-3. The part number for am SI100 version of that probe will be 971100-S100. The part number for an SI200 version of that probe would be 971100-S200. Future product variations for Orbit® ACS will mean new suffixes as well.

|

|

|

|

|

|

|

|

|

Orbit ACS Applications

Solartron Metrology, the world leader in linear measurement, introduces Orbit® ACS, which stands for Automation and Control Systems. Available to both end users and automation OEMs, the new units verify key dimensions to support quality control in electronic, semiconductor, automotive and other manufacturing applications. Users can quickly set up the digital probe and process limits on the integral keypad and screen; no programming is required. Output to a PLC can be accomplished by several protocols including Modbus over RS232 or RS485,or RS232 output. Three lines of discrete digital output and four lines of discrete digital inputs are available.

|

|

Related products:

SI100 / 200 SI100 / 200

Download Application Story:

|

|

|

|

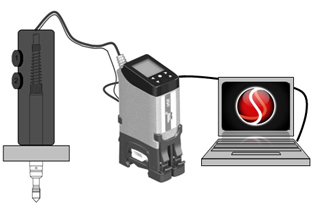

Manual measuring station with SI100

The time consuming and error ridden method of hand writting measurements from vernier callipers can be replaced with a Digital Probe. This construction combined with an SI100 enables the measurement station to supply the values to a PC via R232 directly into the table.

|

|

|

|

|

|

|

|

|

|

|

|

SI400 - Specification

|

Product

|

|

|

|

|

|

|

Spring Push Axial Cable

|

SI400P/1/S

|

SI400P/10/S

|

SI400P/10/S

|

SI400P/20/S

|

SI400P10/2S

|

|

Spring Push Radial Cable

|

|

SI400PR/5/S

|

SI400PR/10/S

|

SI400PR/20/S

|

SI400PR10/2/S

|

|

Spring Push Axial Cable Feather Touch

|

|

SI400T/5/S

|

SI400T/10/S

|

SI400T/20/S

|

SI400T10/2S

|

|

Spring Push Radial Cable Feather Touch

|

|

SI400TR/5/S

|

SI400TR/10/S

|

SI400TR/20/S

|

SI400TR10/2S

|

|

Pneumatic Axial Cable

|

|

SI400P/5/P

|

SI400P/10/P

|

SI400P/20/P

|

SI400P10/2S

|

|

Pneumatic Radial Cable

|

|

SI400PR/5/P

|

SI400PR/10/P

|

SI400PR/20/P

|

SI400PR10/2/P

|

|

Pneumatic Axial Cable Feather Touch

|

|

SI400T/5/P

|

SI400T/10/P

|

SI400T/20/P

|

SI400T10/2S

|

|

Pneumatic Radial Cable Feather Touch

|

|

SI400TR/5/P

|

SI400TR/10/P

|

SI400TR/20/P

|

SI400TR10/2S

|

|

|

|

|

|

|

|

|

Measurement Performance

|

|

|

|

|

|

|

Measurement Range

|

1

|

5

|

10

|

20

|

2

|

|

Accuracy (% of Reading) (Note 1)

|

0.2

|

0.15

|

0.15

|

0.15

|

0.2

|

|

Repeatability (worst case) μm (Note 2)

|

0.15

|

0.15

|

0.15

|

0.15

|

0.15

|

|

Repeatability (typical) μm (Note 3)

|

0.05

|

0.05

|

0.07

|

0.07

|

0.05

|

|

Resolution (μm)

|

0.01

|

0.05

|

0.05

|

0.1

|

0.01

|

|

Pre Travel (mm)

|

0.15

|

0.15

|

0.15

|

0.15

|

0.15

|

|

Post Travel (mm)

|

0.35

|

0.85

|

0.85

|

0.85

|

8.85

|

|

Tip Force (N) at Middle of Range ±20%

|

|

|

|

|

|

|

Spring Push

|

0.7

|

0.7

|

0.7

|

0.7

|

0.7

|

|

Spring Push Feather Touch

|

0.3

|

0.3

|

0.3

|

0.3

|

0.3

|

|

Pneumatic at 0.4 bar

|

N/A

|

0.7

|

0.7

|

0.7

|

0.7

|

|

Pneumatic 1 bar

|

N/A

|

2.6

|

2.6

|

2.6

|

2.6

|

|

Pneumatic Feather Touch ±30% at 0.3 bar

|

N/A

|

0.18

|

0.18

|

0/18

|

0.18

|

|

Pneumatic Feather Touch ±30% at 1 bar

|

N/A

|

1.1

|

1.1

|

1.1

|

1.1

|

|

Pneumatic Jet

|

N/A

|

0.85

|

0.85

|

0.85

|

0.85

|

|

Temperature Coefficient %FS/ºC

|

0.01

|

0.01

|

0.01

|

0.01

|

0.01

|

|

|

|

|

IP65 with gaiter or IP50 without gaiter

|

Sealing for Probe Interface Electronics

|

Top and Front: IP41, Rear: IP20, In line connector: IP67

|

|

|

-20 to +70

|

Probe Operating Temperature with Gaiter (ºC)

|

+5 to +80

|

Probe Operating Temperature without Gaiter (ºC)

|

-10 to +80

|

Electronics Operating Temperature (ºC)

|

0 to 60

|

|

|

Emissions EN61000-6-3, EN61326

|

|

|

Immunity EN61000-6-2, EN61326

|

|

|

18 to 32 VDC @ 0.07A typical

|

|

|

|

|

Stainless Steel

|

|

|

Nylon, Ruby, Silicon Nitride, Tugsten Carbide

|

|

|

Fluoroelastomer

|

|

|

PUR

|

|

|

ABS

|

|

Electronics interface (Orbit® ACS)

|

Alarm Outputs - selectable High, OK, Low

|

3 outputs either NPN, PNP, logic Programmable Active Hi or Lo

|

Discrete inputs - user selectable

|

4 inputs user configurable eg. Print, Zero, Preset

|

Update Rate for I/O Discrete (ms)

|

5

|

Bandwidth of Electronics (Hz) - User selectable

|

460, 230, 115, 58, 29, 14, 7, 4

|

|

Communications interface protocol

|

MODBUS (RTU or ASCII) or Solartron Serial Formats

|

|

Communications interface Hardware

|

RS485 or RS232 (User selectable) Up to 115,200 Baud

|

Update Rate for Serial Data (ms)

|

25

|

Note 1: Accuracy 0.1 μm or % reading whichever greater

Note 2: Obtained by repeated operation against a carbide target with side load applied to the bearing using max-min

Note 3: Obtained by repeated operation against carbide target standard devotion from average (68%)

|

|

|

|

|

|