Measuring the surface shape of contact lenses and molds

In order to control and optimize processes, the front and back of the contact lens are measured with incident light during the production process. Molds and tools are measured as well as the calculation of tool offsets. |

Measuring the optical quality of flat optics

High demands are often placed on the quality of optical filters and windows. Optocraft offers turnkey solutions for measuring wavefront errors in transmitted light and surface defects. |

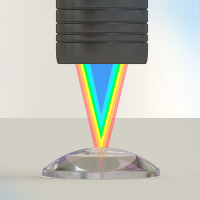

Measuring the curvature of lenses

In order to meet production tolerances, the contour of optical lenses such as eyeglass lenses or objectives, confocal chromatic sensors are used. Based on the distance values, statements about the surface properties can also be made. The sensors enable a large tilt angle which means they can also detect highly curved surfaces. |

Camera auto focus measurement

Confocal sensors measure the distances between the auto focus lenses to provide the camera with the highest possible image quality. |

Surface inspection of mirrors

With optical components such as mirrors, a high degree of surface homogeneity is required. reflectCONTROL sensors are used to test the reflecting surfaces of these reflecting surfaces. They detect and classify surface deviations on the mirror surface. |

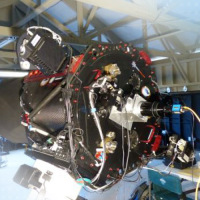

Quality assurance based on multi-functional optical testing

Optical systems are used in a wide variety of industries and applications, including a wide range of products from micro-optics with dimensions in the μm range to telescope lenses with diameters of several meters. Optocraft delivers multifunctional systems based on the Shack-Hartmann wavefront technology for optics testing. Providing information about the quality of the optics based on precise wavefront measurements, these measuring systems contribute to the optimization of development and manufacturing processes. |

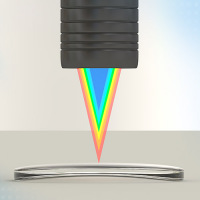

Measuring the center thickness of lenses

In order to meet production tolerances, the center thickness of optical lenses such as eyeglass lenses or objectives is measured using confocal chromatic sensors. The measurement is performed from one side and can also be carried out with very thin lenses. |

Nanometer positioning in lithography machines

To illuminate individual components on the wafer, the lithographic devices move the wafer to the respective position. Capacitive displacement sensors measure the position of the travel path in order to enable nanometer-accurate positioning. |

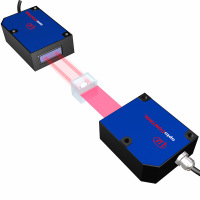

Measurement of contact lenses

Contact lens manufacturers have a need to conduct various material tests on clear, flexible polymer samples. The material samples must be submerged during testing in a saline solution for hydration. The highly sophisticated ThruBeam model ODC2600-40 is uniquely capable of making dimensional measurements with high accuracy and speed. |

High precision thickness measurement of silicon wafers

Capacitive displacement sensors are used for the exact thickness measurement of wafers. Two opposing sensors detect the thickness and also determine other parameters such as deflection or sawing marks. The position of the wafer in the measuring gap may vary. |