|

|

|

|

|

|

|

|

Air Gauge to Orbit

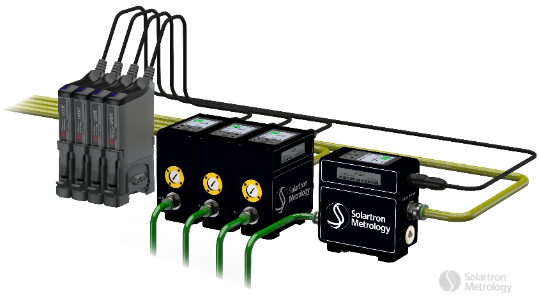

Solartron Metrology’s Orbit Air Gauge Interface Module (AGM) makes connecting air gauge Measurement Probes to Orbit simple, allowing the user to mix air gauges with all of our contact and non contact sensors to fully utilise the full performance of the Orbit Digital Measurement Network

Combining multiple sensors using the Orbit Digital Measurement network is easy and data can be read using a Solartron readout or the Gauge Computer Software making system integration simple.

Attention to detail in both design and manufacture of the displacement sensor ensures precision measurement throughout the linear displacement transducer's life.

Solartron Metrology offers a large range of displacement sensors to suit multiple applications with different cable outlets (radial or axial), multiple measuring ranges, different cable types like steel braided which provides additional protection for displacement sensors that are being used in harsh environments.

|

|

|

|

|

-

Interfaces to most Air Gauge spindles, mandrels or bore heads Interfaces to most Air Gauge spindles, mandrels or bore heads

-

High stability Air to Orbit Converter High stability Air to Orbit Converter

-

Resolution better than 0.1 µm Resolution better than 0.1 µm

-

Pressure 30 psi Pressure 30 psi

-

Simple set up and Mastering using Orbit or integral screen Simple set up and Mastering using Orbit or integral screen

|

|

|

|

|

|

|

|

|

|

|

|

|

|

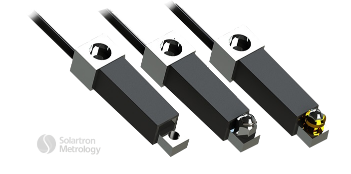

Spring, Pneumatic Push and Vacuum Retract Probes

Contact gauge probes often provide the most cost effective solution for a wide range of measuring and positioning applications.

In a conventional pencil probe the tip is pushed out using an internal spring. When installed in a fixture it is frequently required to design a mechanism to bring the probe into contact with the part being measured.

A pneumatic probe (either pneumatic push or vacuum retract) allows the number of parts in the fixture to be reduced resulting in improved reliability and reduced fixture cost. It also allows for fast automatic loading of the part into the gauge as the probe tip can be in the fully ‘retract position’ when this is occurring. Probes such as the AX/5/1 have a mechanical movement of 10 mm with a calibrated range of ±1 mm at the beginning of the movement.

|

|

|

|

|

-

Displacement transducer measuring ranges ±0.25, ± 0.5, ± 1, ± 1.5, ± 2,5, ± 5, ± 10 mm Displacement transducer measuring ranges ±0.25, ± 0.5, ± 1, ± 1.5, ± 2,5, ± 5, ± 10 mm

-

Linearity better than 0.5% of measurement Linearity better than 0.5% of measurement

-

Repeatability precision better than 0.05 µm Repeatability precision better than 0.05 µm

-

Range of contact sensor tips for different applications Range of contact sensor tips for different applications

-

Spring actuation Spring actuation

-

Standard contact sensor tip force of 0.7 N (options available) Standard contact sensor tip force of 0.7 N (options available)

-

IP65 sealing (fully sealed options available) IP65 sealing (fully sealed options available)

-

Inductive sensors with excellent side load capability Inductive sensors with excellent side load capability

-

Linear Variable Differential Transformer (LVDT) or Half Bridge options Linear Variable Differential Transformer (LVDT) or Half Bridge options

|

|

|

|

|

-

± 1, ± 2,5, ± 5, ± 10 mm displacement transducer measuring ranges ± 1, ± 2,5, ± 5, ± 10 mm displacement transducer measuring ranges

-

Linearity better than 0.5% of precision measurement Linearity better than 0.5% of precision measurement

-

Repeatability precision better than 0.05 µm Repeatability precision better than 0.05 µm

-

Range of contact sensor tips available Range of contact sensor tips available

-

Pneumatic actuation Pneumatic actuation

-

Standard contact sensor tip force of 0.7N (options available) Standard contact sensor tip force of 0.7N (options available)

-

IP65 sealing (fully sealed options available) IP65 sealing (fully sealed options available)

-

Inductive sensors with excellent sideload capability Inductive sensors with excellent sideload capability

-

Linear Variable Differential Transformer (LVDT) or Half Bridge options Linear Variable Differential Transformer (LVDT) or Half Bridge options

-

Displacement sensors available with vacuum retract Displacement sensors available with vacuum retract

|

|

|

|

|

-

± 1, ± 2,5, ± 5, ± 10 mm displacement transducer measuring ranges ± 1, ± 2,5, ± 5, ± 10 mm displacement transducer measuring ranges

-

Linearity better than 0.5% of precision measurement Linearity better than 0.5% of precision measurement

-

Repeatability precision better than 0.05 µm Repeatability precision better than 0.05 µm

-

Range of contact sensor tips available Range of contact sensor tips available

-

Pneumatic actuation using piston - still operates if gaiter damaged Pneumatic actuation using piston - still operates if gaiter damaged

-

Standard contact sensor tip force of 0.7N (options available) Standard contact sensor tip force of 0.7N (options available)

-

IP50 sealing (fully sealed options available) IP50 sealing (fully sealed options available)

-

Inductive sensors with excellent sideload capability Inductive sensors with excellent sideload capability

-

Linear Variable Differential Transformer (LVDT) or Half Bridge options Linear Variable Differential Transformer (LVDT) or Half Bridge options

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Orbit Power Supplies and Accessories

Solartron supply quality regulated power supplies for the Orbit® Measurement System in a number of configurations. We highly recommend the use of these to ensure optimum performance.

|

|

|

|

|

-

AC Power In, 5 VDC Out AC Power In, 5 VDC Out

-

DC Power (24 VDC) In, 5 VDC Out DC Power (24 VDC) In, 5 VDC Out

-

Power up to 32 Modules depending on type Power up to 32 Modules depending on type

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Single Leaf flexures & Mini probes

The Miniature Single Leaf Flexure is another variant of flexure based contact probes. The miniature single leaf flexure has a calibrated range of 0 – 500 microns and provides the means for alternative configurations of contact tip mounting. The gauge body mounting to the fixture is accomplished using a single M2.5 screw. Contact tip mounting is attached by using either the integral M3 locking thread insert, primarily intended for use with length extensions, OEM’s fixed length contact tips or with Solartron’s tip adapter, which when applied with Solartron’s dedicated tip allows for 1 mm of height adjustment. OEM tips may be fitted to either option, but it is advised that the height be limited to a maximum of 6 mm above the gauge top surface, to avoid significantly prejudicing gauge life and repeatability. Mid adjustment range is the reference point for the calibration using the standard tip. Length extensions may be applied to this style of gauge but should be used with care. A maximum length of 12 mm, between tip and mounting thread, is advised, but this does depend on other variables such as tip height approach angle and measurement deflection – extremes of these conditions will significantly reduce the gauge life and severely degrade the repeatability. To enable direct reading of the gauge using extensions, the use of a software multiplier will be necessary. However, as the reference dimension for the gauge is 18 mm by using a 12 mm extension, a range of 833 microns is achieved but a reading of only 500 microns is observed.

Combining multiple sensors using the Orbit Digital Measurement network is easy and data can be read using a Solartron readout or the Gauge Computer Software making system integration simple.

Attention to detail in both design and manufacture of the displacement sensor ensures precision measurement throughout the linear displacement transducer's life.

Solartron Metrology offers a large range of displacement sensors to suit multiple applications with different cable outlets (radial or axial), multiple measuring ranges, different cable types like steel braided which provides additional protection for displacement sensors that are being used in harsh environments.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Single Leaf flexures & Mini probes

With the same advantages as the parallel flexure the single leaf flexure offers the gauge builder access to even more measurement points. With careful use of extension arms measurements can be made inside slots or between features where a conventional pencil probe cannot reach.

Combining multiple sensors using the Orbit Digital Measurement network is easy and data can be read using a Solartron readout or the Gauge Computer Software making system integration simple.

Attention to detail in both design and manufacture of the displacement sensor ensures precision measurement throughout the linear displacement transducer's life.

Solartron Metrology offers a large range of displacement sensors to suit multiple applications with different cable outlets (radial or axial), multiple measuring ranges, different cable types like steel braided which provides additional protection for displacement sensors that are being used in harsh environments.

|

|

|

|

|

|

|

|

|

|