|

General Functionality

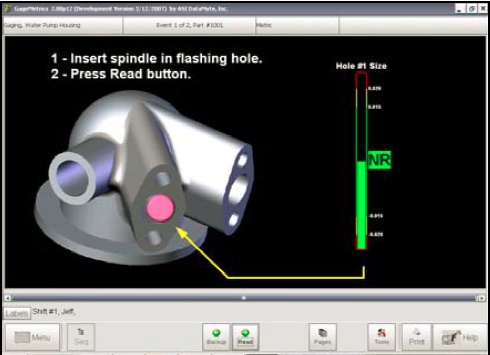

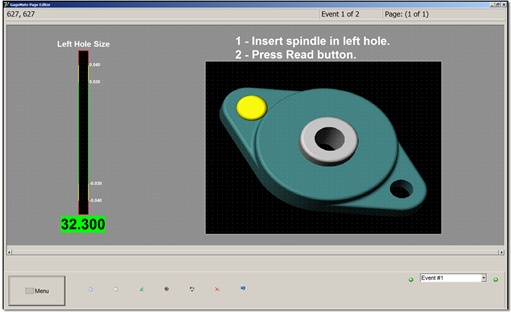

Orbit® Gauge Software Data Collection Module Embedded graphics in Orbit® Gauge Software's Data Collection Module let you customize each measurement screen to simplify training and operation. Part status is indicated by red, green, and yellow graphics, with customizable flashing symbols to guide the operator through the measurement sequence. This also helps users to distinguish which hole to measure when the same gage is inspecting multiple holes

The part status screen shows complete status for all measurements recorded for the part. It’s colour coded summary makes it easy to determine at a glance the status of the part The part status screen shows complete status for all measurements recorded for the part. It’s colour coded summary makes it easy to determine at a glance the status of the part

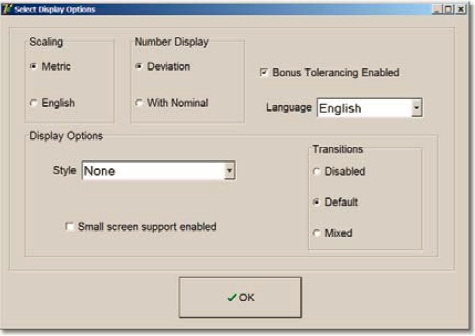

Display Options

The Display Options feature lets you customize the operator screens. It also gives you the ability to change from Metric to English scaling or from deviation from nominal or full engineering number displays on the fly

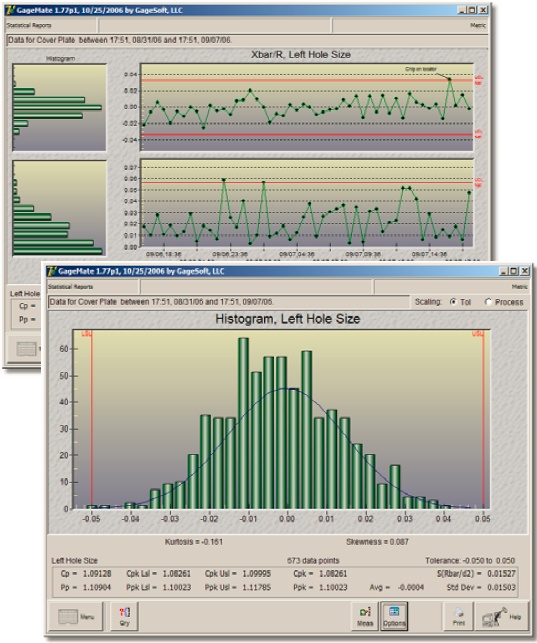

SPC Charting SPC Charting

Orbit® Gauge Software comes equipped with these charts: Statistical Summary, Histogram, X-bar and R,X-bar and S, X and MR, and Run Chart for analysis of data. These charts assist the user by tracking process performance. They also allow for filtering data to find the root cause so the process can be corrected before a part needs to be scrapped

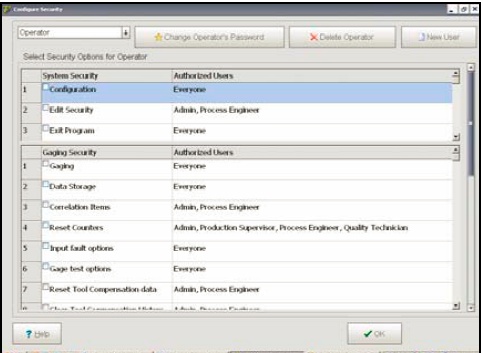

Security

Complete Security is designed into Orbit® Gauge Software, preventing any unwanted changes to the setup. This security protects the integrity of the measurement system and can be customized to meet your needs Complete Security is designed into Orbit® Gauge Software, preventing any unwanted changes to the setup. This security protects the integrity of the measurement system and can be customized to meet your needs

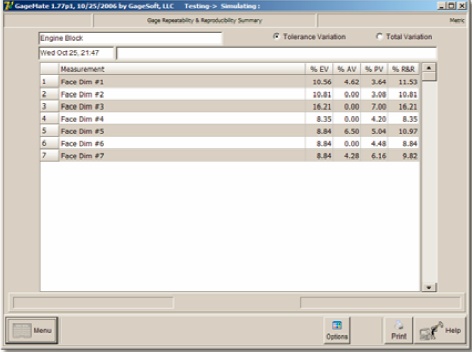

Gage Repetability and Reproducibility Gage Repetability and Reproducibility

Orbit® Gauge Software has the capability to perform gage repeatability and reproducibility studies in compliance with the AIAG MSA Fourth Edition. You can select Operator, Trial, and Part inspection order as well as maintain a history for all GR&R studies performed.

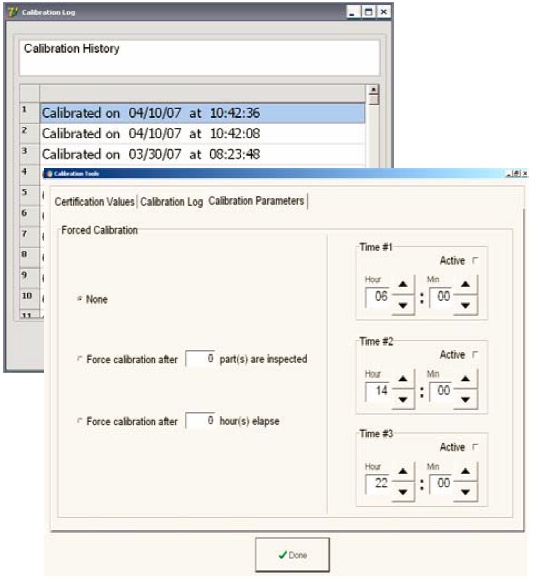

Mastering Orbit® Gauge Software can prompt you when to master the gage based on time or number of parts manufactured. Consistent timed mastering procedures ensure that the gage will be properly calibrated to check the parts produced. Orbit® Gauge Software also saves each mastering sequence with a date and time stamp. This feature lets you track the mastering events to assist in troubleshooting the gage and to see if mastering has been completed on a timely basis. Multiple master sets are supported with different certification values for each allowing you to select which set is to be used without any additional changes to the program Orbit® Gauge Software can prompt you when to master the gage based on time or number of parts manufactured. Consistent timed mastering procedures ensure that the gage will be properly calibrated to check the parts produced. Orbit® Gauge Software also saves each mastering sequence with a date and time stamp. This feature lets you track the mastering events to assist in troubleshooting the gage and to see if mastering has been completed on a timely basis. Multiple master sets are supported with different certification values for each allowing you to select which set is to be used without any additional changes to the program

Orbit® Gauge Software Set Up Editor

The Orbit® Gauge Software Setup Editor (Orbit® Gauge Software SE) provides access to the Orbit® Gauge Software configuration tools. Orbit® Gauge Software SE provides everything necessary to define inspection sequences and part measurements, including custom gauge screens to lead the operator through the inspection process. Orbit® Gauge Software SE can be used to create applications for manual, semi-automatic, and automatic gauge applications.

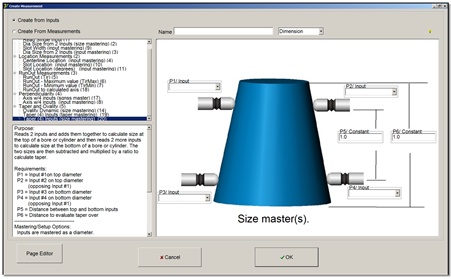

Creating Measurements Creating Measurements

Orbit® Gauge Software incorporates measurement templates to assist you with measurement formulas. Users can create equations simply by selecting the desired template and entering the required values. This reduces the need for operator training and speeds up the measurement creation process.

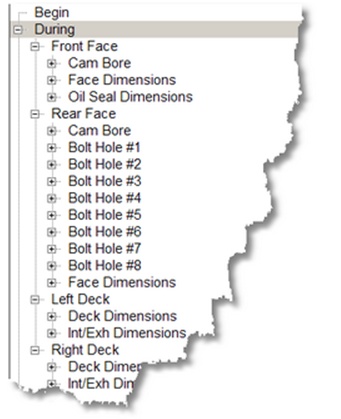

Inspection Sequence

-

The inspection sequence is displayed visually allowing for an easy understanding of the inspection process. The inspection sequence is displayed visually allowing for an easy understanding of the inspection process.

-

Inspection sequences can be easily modified using drag and drop operations. Features, Feature Groups, Events, and measurements can all be moved using drag/drop operations. When an object is dragged to another location of the sequence, all pages and measurements go with it. What use to take many hours can now be done in minutes. Inspection sequences can be easily modified using drag and drop operations. Features, Feature Groups, Events, and measurements can all be moved using drag/drop operations. When an object is dragged to another location of the sequence, all pages and measurements go with it. What use to take many hours can now be done in minutes.

-

All sequence objects can also be copied. Copying an event also copies all pages and measurements belonging to the event. This virtually eliminates time consuming repetitive operations. All sequence objects can also be copied. Copying an event also copies all pages and measurements belonging to the event. This virtually eliminates time consuming repetitive operations.

-

Events can be named for easy reference. Events can be named for easy reference.

-

The sequence can be created so that the operator can dynamically select which portions of it he wishes to perform when inspecting the part The sequence can be created so that the operator can dynamically select which portions of it he wishes to perform when inspecting the part

-

Faulty inputs can be disabled. The input is then automatically removed from the master sequence and all measurements using the input are also disabled. If all measurements taken on an event are disabled, the event is automatically suppressed. This can be of great use for those customers unable to maintain spare parts inventory Faulty inputs can be disabled. The input is then automatically removed from the master sequence and all measurements using the input are also disabled. If all measurements taken on an event are disabled, the event is automatically suppressed. This can be of great use for those customers unable to maintain spare parts inventory

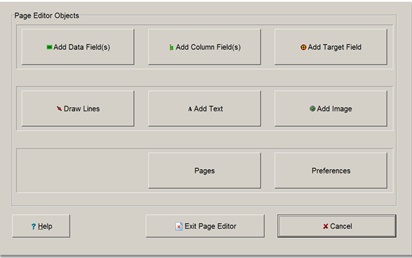

Page Editor Page Editor

-

Custom pages can be created for operators to view. Custom pages can be created for operators to view.

-

All measurements are colour coded for easy determination of measurement accept/reject status. All measurements are colour coded for easy determination of measurement accept/reject status.

-

Pages allow all measurement data to be viewed in a format of your choice. Pages allow all measurement data to be viewed in a format of your choice.

-

Multiple pages are allowed for each event for display of reference information such as probe locations and gage maintenance recommendations Multiple pages are allowed for each event for display of reference information such as probe locations and gage maintenance recommendations

-

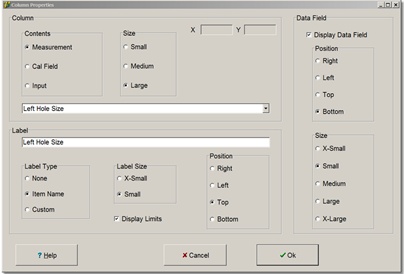

Dynamic page objects include data fields, column fields, and Dynamic page objects include data fields, column fields, and  target fields for use with true position measurements. target fields for use with true position measurements.

-

Static page objects include lines, text, and images Static page objects include lines, text, and images

-

Data and column fields are available in a variety of sizes and can automatically display measurement names and limits. Data and column fields are available in a variety of sizes and can automatically display measurement names and limits.

-

Measurement names and limits are automatically positioned to the top, bottom, left, or right of a field. Measurement names and limits are automatically positioned to the top, bottom, left, or right of a field.

-

If a measurement name or limit is changed, all screens automatically update. If a measurement name or limit is changed, all screens automatically update.

|