|

|

|

|

Flexible Endoscopes - ELTROTEC Flex

Endoscopic tasks often require flexible probes in order to access the desired point in concealed openings, interior cavities or in bent pipes or entrances. ELTROTEC Flex endoscopes are available in a range of lengths and diameters. With a diameter of 2.5 mm and larger they are equipped with a control mechanism for changing the angle of the probe tip.

|

Flexible Micro-Endoscope

ELTROTEC Flex MTFS are miniature flexible fiber-optical endoscopes which serve as valuable tools and inspection devices in many areas of quality assurance. Despite their extremely small outer diameter the flexible micro-endoscopes are high quality instruments with a resolution of up to 30,000 image points suitable for the inspection of miniature components and channels in the fields of microelectronics, precision mechanics and research.

Features:

-

Ø 0.5 to 2.5 mm

-

Lengths: 500 mm to 15,000 mm

-

Inspection of the smallest components

-

70° angular field of view

|

|

|

Top-Line Flexible Endoscopes

Flexible Top-Line endoscopes are equipped with a resolution of 18,000 image points Higher definition and stronger contrast is achieved with the compensated light conductor bundle.

The Top-Line Semi-Flexibel is 1 m long and has a flexible probe. A probe tip with angular offset and lengths of up to 1200 mm characterise the Flexibel Pro model. Unique image brilliance, quality and functionality distinguish Flexibel Pro endoscopes.

Both endoscopes are available as a complete set with light source and mirror head.

Features:

-

Ø 2.5 to 7.9 mm

-

Lengths: 800 mm to 1200 mm

-

Equipment as complete set

-

High resolution, distortion-free images

Complete set:

-

Top-Line flexible endoscope

-

90° mirror head (with Flexibel Pro Ø 5 mm, optional 90° prism head)

-

Top-Line SuperNova light source

-

Robust aluminum case

-

Li-Ion battery with charging device

|

|

|

|

|

|

|

|

|

Rigid endoscopes – ELTROTEC borescopes

ELTROTEC rigid borescopes were developed for the visual inspection of small bore holes and cavities. With diameters ranging from 0.7 to 25mm, they offer excellent image reproduction and with their excellent resolution and brightness facilitate the inspection of the smallest details. The Top-Line premium endoscopes are equipped with graded index lenses (GRIN lenses), providing the highest quality with no appreciable image loss.

|

Standard endoscopes SKF-D

The ELTROTEC SKF-D endoscope is the standard amongst the rigid endoscopes. The most appropriate model for a variety of applications can be selected from the wide product range. With its integrated focussing, a clear image of the target object can be obtained from every distance. If a mirror tube is used the viewing direction can be adjusted by turning the hand wheel. Even with an angled viewing direction large angular fields of view are possible.

Features:

-

Ø 2.8 to 10 mm

-

Lengths: 125 to 1036 mm

-

Optimized light conductors

-

Dioptre adjustment

|

|

|

Endoscope with swing-prism – MKF-D

The unique feature of the ELTROTEC MKF-D is its integrated swing-prism enabling the viewing direction to be changed between -7° and 133° as desired. Using just one finger the viewing direction can be altered using the hand wheel on the control element. The angular field of view of 45° provides a sufficiently large visible region. The entire region in front of the endoscope can be inspected by moving the prism as the lens can also be rotated.

Features:

-

Ø4.3 to 14 mm

-

Lengths: 175 to 1,505 mm

-

Swivelling lens -7° to 133°

-

Rotatable through 370°

|

|

|

Miniature Endoscopes - PFK

The miniature endoscope ELTROTEC PKF is ideally suited for the inspection of miniature components and channels in the field of microelectronics and precision engineering. With only 0.7 mm diameter it is one of the smallest rigid endoscopes. The low light transmission due to its small diameter is compensated for through the use of high quality graded index lenses (GRIN lenses).

Features:

-

Ø 0.7 to 2.0 mm

-

Lengths: 29.5 to 234 mm

-

High quality crisp rigid glass lens optics

-

50° angular field of view

|

|

|

Flexible Miniature Endoscopes - ME

The miniature endoscope ELTROTEC ME is ideally suited for the inspection of miniature components and channels in the field of microelectronics and precision engineering. In distinction to other miniature endoscopes with a gradient index lens, the ME can also be lightly bent without suffering damage. The image quality is comparable to that of all conventional lens systems.

Features:

-

Ø 0.9 to 2.0 mm

-

Lengths: 20 mm to 450 mm

-

Flexible

-

High quality silica fibers

|

|

|

Mobile Endoscopes with Halogen Illumination

The ELTROTEC SWS is equipped with a light intensive halogen lamp on the probe tip. This enables large cavities to be effectively illuminated. It is used e.g. for inspecting insulation in cavity walls, beams and wooden constructions. This model is also frequently employed for building refurbishment, stone drill holes and for inspecting exhaust gas paths. The integrated accumulator allows the endoscope to be flexibly transported to all deployment sites. Alternatively mains operation is possible.

Features:

-

Ø 8 mm

-

Length: 400mm

-

Accumulator operation possible

-

Warm light source in probe tip

|

|

|

Top-line rigid standard endoscopes

Top-line endoscopes are highly sophisticated endoscopy devices. The mature technology provides a high light yield and sharply defined objects. This is supported by a multi-coated objective lens and modern GRIN lens technology.

Thus it is possible to generate better imaging with a smaller endoscope diameter. Top-Line endoscopes are supplied with a comprehensive range of accessories as standard in the form a complete set. The endoscopes are equipped with a Mini Maglite light source.

Features:

-

Ø 2.4 to 6.35mm

-

Lengths: 102 mm to 560 mm

-

Larger, brighter images

-

Newly designed and multi-coated objective lenses

-

Focal point: 2mm to ∞

Shot-Kit:

Top-Line endoscopes with a Ø of 4.2 mm are ideal for inspecting gun barrels for rust, scoring, chatter marks and signs of abrasion.

|

|

|

Eltrotec Pro rigid endoscopes

Rigid ELTROTEC Pro precision endoscopes complete the proven advantages of the Top-Line series by first-class quality of the special multi-coated lenses combined with modern GRIN lens technology. These endoscopes are designed for the professional user. Other high quality characteristics include a focus ring and an optimized fiber optic connector for high light yield. This is why these endoscopes are ideal for adapting to a camera.

Features:

-

Ø 1.85mm to 7.2m

-

Lengths: 50mm to 940mm

-

Latest endoGRINs® image transmission lense

-

Separate focus ring for user-friendly video and image recordin

-

Temperature range - 20 °C to 120 °C, up to 300 °C as an option

-

Focal point from 2mm to ∞

|

|

|

|

|

|

| |

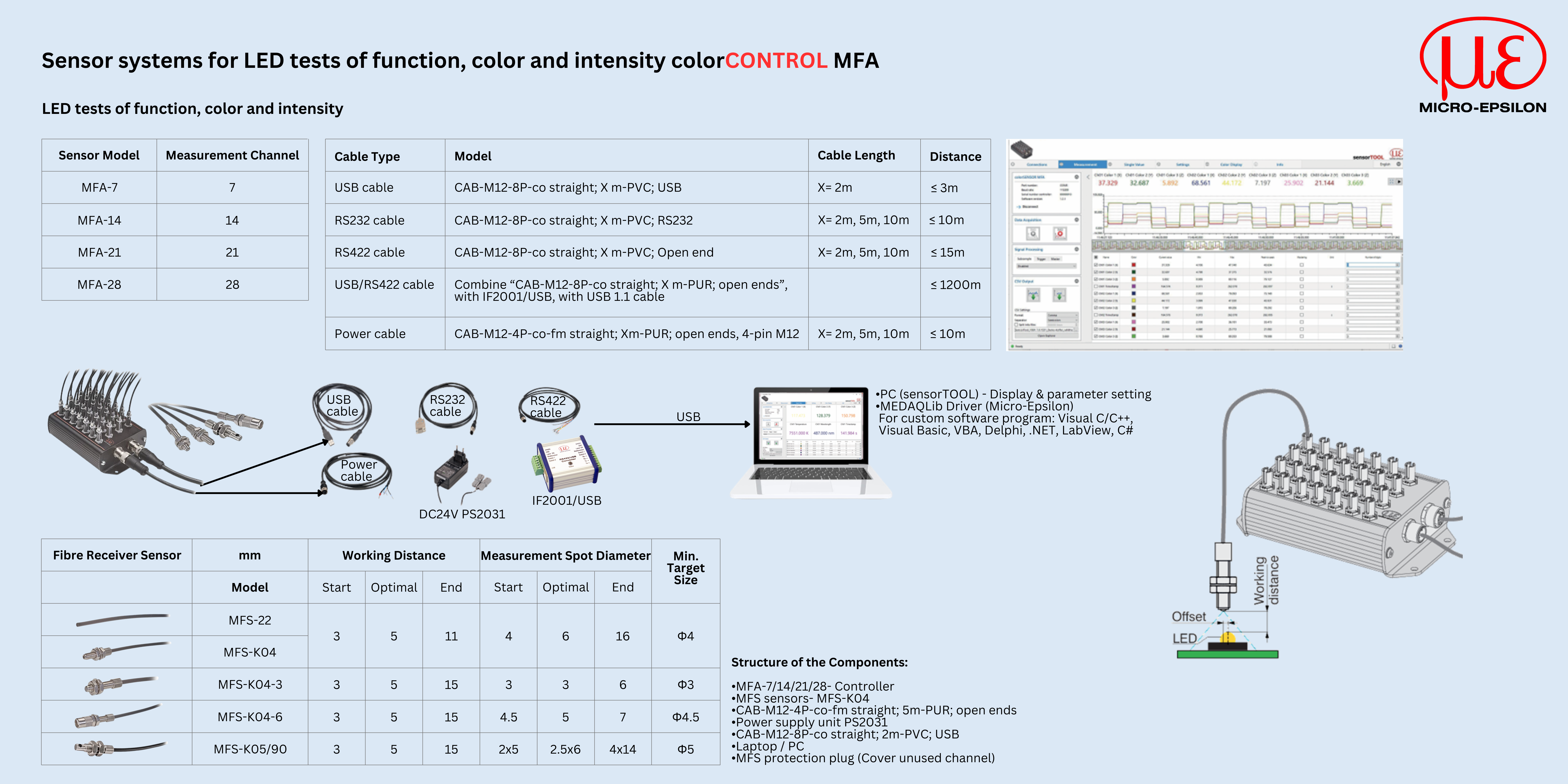

Sensor systems for LED color and intensity tests

|

| |

|

|

| The colorCONTROL MFA is used for flexible color inspections and intensity testing of LEDs, displays and colored objects. The flexible positioning of the sensors in relation to the objects, as well as their high repeatability, measuring rates and dynamics are particularly favorable. One colorCONTROL MFA monitors up to 28 test objects simultaneously. |

| |

|

|

| |

Sensors

Operating the colorSENSOR MFA controller requires sensors that are used on the measuring point. The sensors reliably detect small light spots from 3 mm and can be individually combined depending on the measurement task. The high-quality receiver sensors with plastic fiber optics are particularly characterized by their small installation dimensions. This enables highly accurate testing at different points for individually arranged test specimens. The sensor portfolio covers a wide range of working distances and spot sizes. Other versions in different lengths and temperature ranges are available as options.

|

| |

| |

|

|

|

Fixed lens color sensors for special targets

|

|

|

|

colorSENSOR OT are fixed lens sensors with True-Color detection. The sensor illuminates the surface with white light and captures and analyzes the reflected color values. They all share the same electronic and utilize different optics for various challenging targets. The internal illumination can be disabled by software so the y can be used on self-luminous tagets as well. |

|

|

|

|

|

Model selection

|

|

|

|

|

|

|

|

|

Universal color sensors with optical fibers

Color sensors of the LT series capture the color in TrueColor quality. This is comparable in quality to the human eye. The electronics consist of a controller to which a variety of optical fibers can be connected. Object distances of up to 100 mm can be realized, thanks to the flexibility of using different optical fibers. Only a very small optical fiber is located on the test object itself. The LT series offers universal sensors in a variety of performance classes.

Optical fibers

Fiber-optic cables are necessary to operate colorSENSOR LT sensors. The Fasop series of optical fibers offers a comprehensive range, which can be individually compiled from the many different versions, depending on the measuring application.

Refer to the optical fiber brochure with advice on selecting the optical fiber for your measuring application.

|

|

|

|

|

|