|

|

|

|

|

|

|

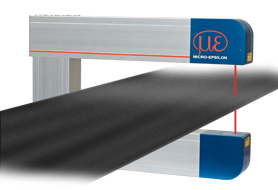

Non-contact inline profile measurement of inner liner material (thickness 1mm to 18mm)

|

|

During the production of inner liner, the thickness profile of inner liner material is measured immediately after the calender using systems of the thicknessCONTROL TIP series. Accurate precision of the non-contact optical system ensures high quality and security of the product produced. Sensors belonging to the thicknessCONTROL RTP series can also be applied for this application.

|

|

|

Benefits

|

-

Permanent high product quality while reducing raw material use Permanent high product quality while reducing raw material use

-

Fast controlling during warm up or product change due to adaptive traversing speed and high-dynamically measurement Fast controlling during warm up or product change due to adaptive traversing speed and high-dynamically measurement

-

No consequential costs due to isotopes or X-rays No consequential costs due to isotopes or X-rays

-

Wear-free measurements instead of half time of radiometric tests Wear-free measurements instead of half time of radiometric tests

-

Highest temperature stability due to in-situ calibration Highest temperature stability due to in-situ calibration

-

Customer-specific adjustable interface Customer-specific adjustable interface

|

|

|

Material parameters

|

-

Material width from 50 mm to 3,800 m Material width from 50 mm to 3,800 m

-

Material feed to 25 m/min Material feed to 25 m/min

-

Permitted material surface temperature max.: 100°C Permitted material surface temperature max.: 100°C

|

|

|

|

Products of the RTP family are designed as C- or O-frames which are equipped with application-specific sensor technology (thru-beam, triangulation or laser line triangulation). |

|

|

|

|

|

|

|

|

The system TIP 8301.EO operates according to a combination principle consisting of a thru-beam sensor, an eddy current sensor and a measuring roller. The eddy current sensor and the thru-beam sensor are applied on an innovative measuring clamp. Since the sensor measures the distance from the clamp to the roller, the lower side of the material is detected. Since the sensor performance is specially aligned with the measuring task a huge measuring gap is possible while offering highest precision. The thru-beam sensor detects the upper side of the material. The thickness of the target is the difference between the two signals. The measuring clamp is equipped with a pneumatically cleaning mechanism and therefore ideal for the application in harsh environment.

Special features:

-

Linearity ±5µm Linearity ±5µm

-

Measuring gap 15mm Measuring gap 15mm

-

Dimensional thickness measurement, independent from material components Dimensional thickness measurement, independent from material components

|

|

|

|

|

|

|

|

|

The TIP 8301.CT is based on the laser triangulation sensors and therefore ensures the measurement being independently from material constants. The system is designed as O-frame, both sensors detect the thickness according to the differential method. In order to ensure highest precision, the laser beams of the sensors are accurately adjusted during the production process using optoelectronic tools which have been specially developed. The system is ideal for monitoring high-dynamically processes due to its high measuring rate. The O-frame mechanics of the system dispose of a compensation frame which does not vary with temperature and which is used in order to avoid temperature fluctuations of the measuring frame using further sensors.

Special features:

-

Linearity ±5µm Linearity ±5µm

-

Measuring gap 18mm Measuring gap 18mm

-

Dimensional thickness measurement, independent from material components Dimensional thickness measurement, independent from material components

|

|

|

TIP 8301.ET

|

|

|

|

|

The TIP 8301.ET is based on the laser triangulation sensors and therefore ensures the measurement being independently from material constants. The system is designed as O-frame, both sensors detect the thickness according to the differential method. In order to ensure highest precision, the laser beams of the sensors are accurately adjusted during the production process using optoelectronic tools which have been specially developed. The system is ideal for monitoring high-dynamically processes due to its high measuring rate. The triangulation sensor applied on the upper side is combined with an eddy current sensor which monitors the distance of the two optical measuring sensors while allowing a software-technical compensation of temperature-induced changes of the measuring gap. Additionally, the compensation sensor is applied according to a special alignment with the measuring task in order to ensure both, a huge measuring gap and highest precision.

Special features:

-

Linearity ±5µm Linearity ±5µm

-

Measuring gap 18mm Measuring gap 18mm

-

Dimensional thickness measurement, independent from material components Dimensional thickness measurement, independent from material components

|

|

|

RTP 8302.T

|

|

|

|

|

The RTP 8302.T is based on the laser triangulation sensors and therefore ensures the measurement being independently from material constants. In order to ensure highest precision, the laser beams of the sensors are accurately adjusted during the production process using optoelectronic tools which have been specially developed. The system is ideal for monitoring high-dynamically processes due to its high measuring rate. The C-frame mechanics of the system disposes of an automated in-situ calibration in order to avoid interferences caused by temperature.

Special features:

-

Linearity from ±5µm Linearity from ±5µm

-

Measuring ranges up to 20mm Measuring ranges up to 20mm

-

Immersion depth from 50° to 1,000mm Immersion depth from 50° to 1,000mm

-

Special sizes on request Special sizes on request

-

Measuring rate to 20kHz Measuring rate to 20kHz

|

|

|

RTP 8302.LLT

|

|

|

|

|

The RTP 8302.LLT is based on the laser line triangulation sensors and therefore ensures the measurement being independently from surface characteristics of the target material. Combined to point sensors, the system offers more precision in the case of gap width. The C-frame mechanics of the system disposes of an automated in-situ calibration in order to avoid interferences caused by temperature.

Special features:

-

Linearity ±10µm, 40mm measuring range Linearity ±10µm, 40mm measuring range

-

Gap width 300mm Gap width 300mm

-

Immersion depth from 50° to 1,000mm Immersion depth from 50° to 1,000mm

-

Special sizes on request Special sizes on request

-

Measuring rate to 2kHz Measuring rate to 2kHz

|

|

|

|

|

|

|

|

|

Measuring and inspection systems for rubber and tires

The rubber processing industry, as well as the tire production process is supported by Micro-Epsilon with a range of systems for inspection, monitoring and control of miscellaneous processes.

|

|

|

|

|

|

|

|

|

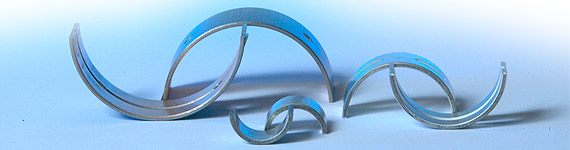

Bearing shells thickness measurement

The quality assurance of bearing shells is determined by the extremely precise specification of several characteristics. Dimensional measured values such as thickness and diameter are also included with the surface quality in the quality inspection. Micro-Epsilon provides several systems using different technologies for the determination of the respective quality criteria.

Advantages:

-

Short cycle times for in-line process

-

No mechanical damages

-

Wear free measurement

-

Easy adaption to diffferent bearing shell diameters

Material parameter:

-

Diameter 30mm to 85 mm

-

Width 15mm to 60mm

-

Thickness 1.5mm to 5mm

|

|

|

|

BS 8251.I

The system for bearing shells thickness measurement is an in-line system for non-contact wall thickness and profile measurement of bearing shells for automotive use. The air cushioning and the completely automatic transport make it possible to inspect up to 60 shells per minute.

|

|

|

|

BWS 8202

The system for bearing shells thickness measurement is an in-line system for non-contact wall thickness and profile measurement of bearing shells for automotive use. The air cushioning and the completely automatic transport make it possible to inspect up to 60 shells per minute.

|

|

|

|

back to product group "Measuring and inspection systems for metal" |

|

|

|

|

|

|

|

|

Non-contact inspection of extruder bores

Applying the IDS 8100.C the diameter of case bores of extruders can be detected precisely. The wear of the machine which has been generated due to abrasive raw material, temperature and pressure can be controlled without contact.

Advantages:

-

Significant reduction of the service time

-

Allows the exchange of defective segments

-

Suitable for all metals without further calibration

-

Local evaluation with touchscreen controller

Material parameter:

-

Housing diameters from 40 mm to 180 mm

-

Diameter variantions 8 or 16 mm

-

Suitable for all metals

|

|

|

|

IDS 8100.C

The IDS 8100.C works with integrated capacitive displacement sensors. The actual bore diameters are detected over the whole process part length. As the axial sensor positions are detected as well using a cable-length measurement system, local deviations in diameter can be reliably and quickly found. In doing so, each sensor position is related to a diameter in the longitudinal axis of the bore hole.

Features:

-

Accuracy 0.04mm

-

Resolution 5mm

-

Max. speed 5 m/s

|

|

|

|

back to product group "Measuring and inspection systems for metal" |

|

|

|

|

|