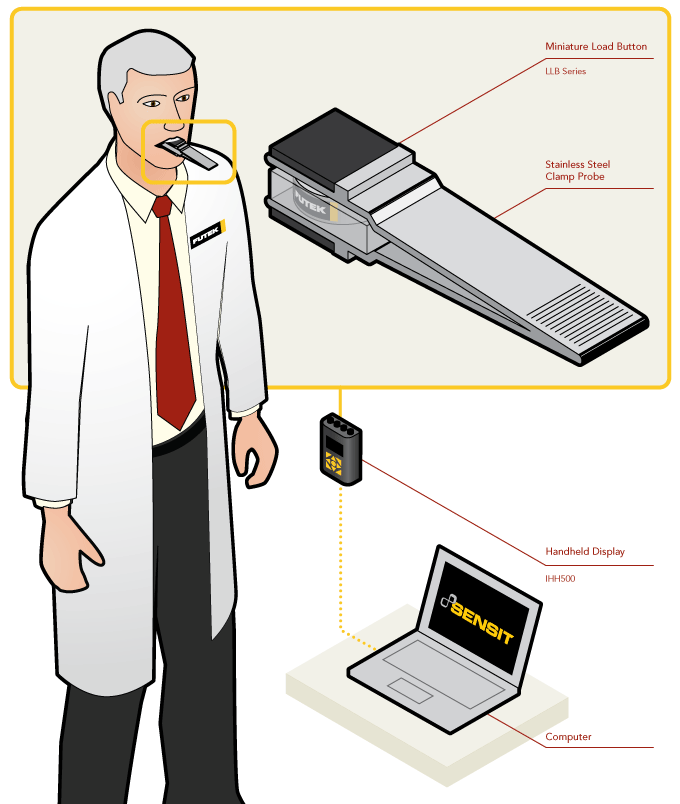

Bite Force Measurement Study

How it Works

- Set up to measure the bite force of dementia patients, researchers at the University of Amsterdam installed FUTEK's Load Buttons between the stainless steel plates of a probe.

- As the patient bites down onto the probe, the force applied is streamed directly to FUTEK's IHH500 Intelligent Digital Hand Held Display where the researchers can monitor the data. If the researchers chooses to utilize FUTEK's SENSIT™ Test and Measurement Software alongside the IHH500, they will then have the ability to live graph and log all the data.

- We should note that FUTEK's Load Buttons are intended for in-line (vertical) measurements.

|

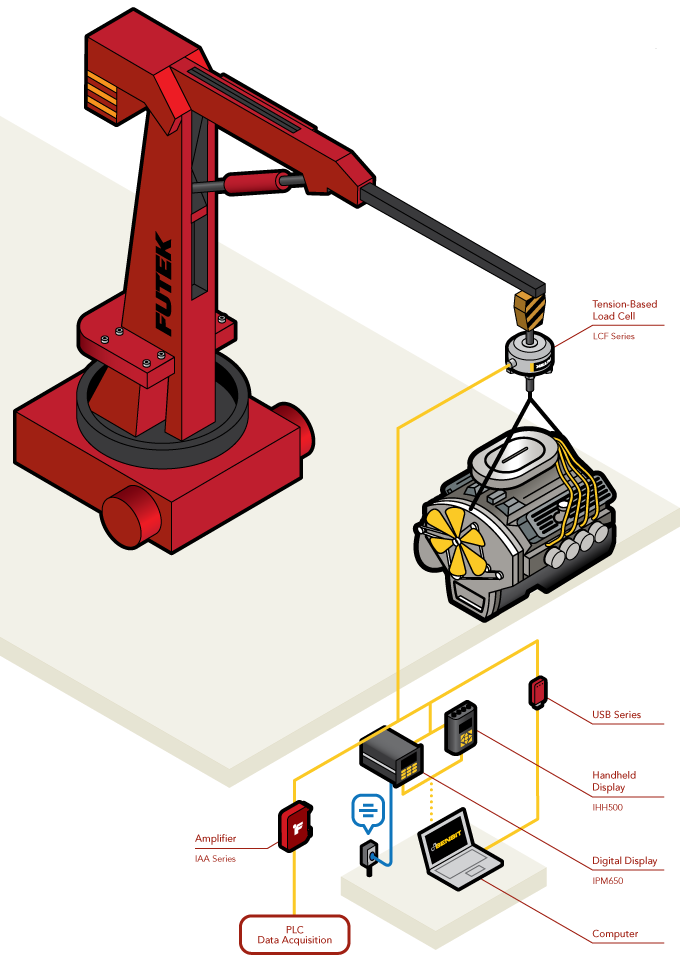

Portable Crane Weighing

How it Works

- Operators and industrial engineers often utilize high capacity, robust load cells to provide the critical verification measurements on portable cranes, as these cranes often endure the weight of a variety of payloads.

- Installed to the crane's cable, FUTEK's Pancake Load Cell (LCF Series) measures the weight of load, as well as the endurance of the cable as it maneuvers the load.

- These measurements can be amplified through an IAA Series Analog Amplifier to a PLC, shown on a digital display (IPM650 or IHH500) or streamed directly to a PC using FUTEK's USB Solutions.

- If the instrument is paired with FUTEK's SENSIT™ Test and Measurement Software operators can log, and graph all the data on the PC.

|

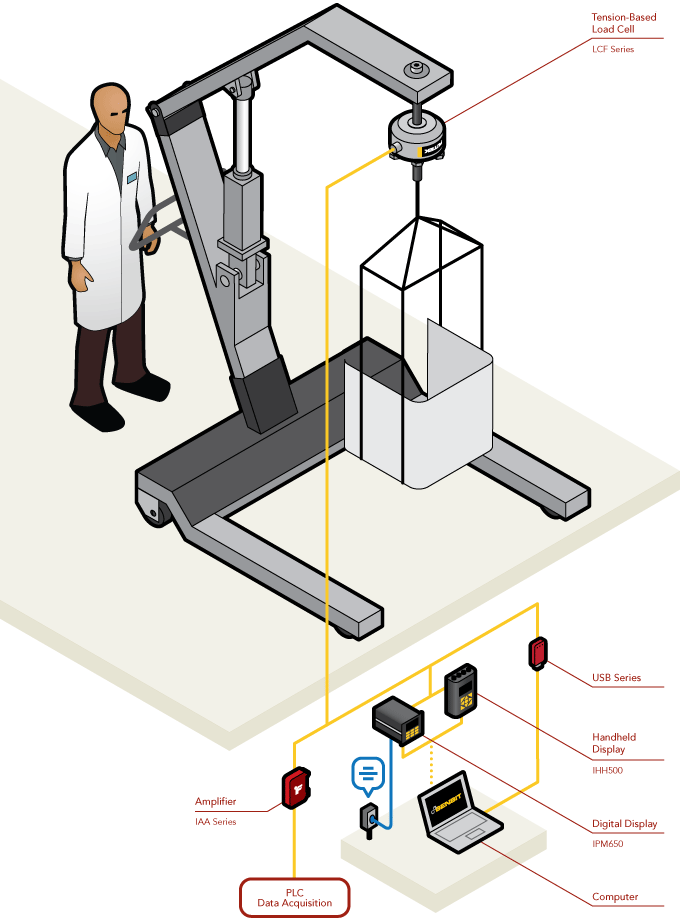

Medical Patient Lift

How it Works

- Medical device engineers often utilize robust load cells to provide the critical verification measurements on patient lifts, being as these lifts support patients of various weights.

- Installed on the lift's cable, FUTEK's Pancake Load Cell (LCF Series) measures the weight of load, as well as the endurance of the cable as it maneuvers each patient.

- These measurements can be amplified through an IAA Series Analog Amplifier to a PLC, shown on a digital display (IPM650 or IHH500) or streamed directly to a PC using FUTEK's USB Solutions.

- If the instrument is paired with FUTEK's SENSIT™ Test and Measurement Software operators can log, and graph all the data on the PC.

|

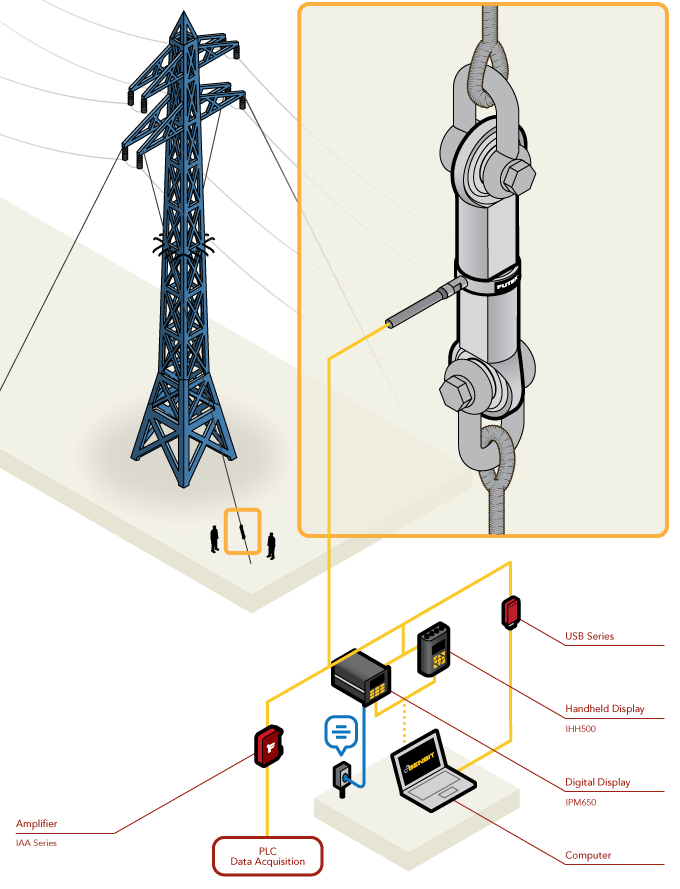

Industrial Wire Tension Measurement

How it Works

- Utilizing FUTEK's LCM Series Miniature Threaded In Line Load Cell coupled with rod end bearings, provides any cable manufacturer with a high-endurance feedback solution.

- Due to its compact size, the LCM Series integrates easily into various cable tension applications.

- As the operator or manufacturer performs this particular cable tension test, results can then be displayed on various instruments or amplified utilizing an IAA Series Analog Amplifier.

- The analog output of the sensor can be taken to either of FUTEK's digital displays - the IHH500 Intelligent Digital Hand Held Display or IPM650 Panel Mount Display - or digitally streamed to FUTEK's USB Solution.

- Pairing any of these instruments with FUTEK’s SENSIT™ Test and Measurement Software allows the collection of all the results.

- Note: For outdoor use, protection from the elements is required. FUTEK offers optional encapsulation to protect from moisture.

|

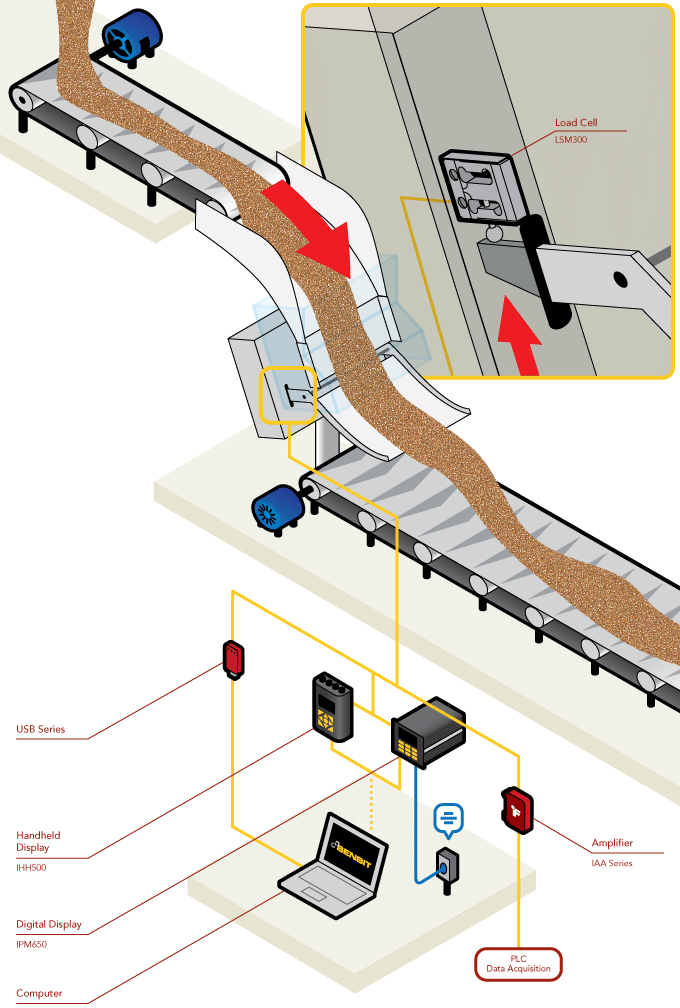

Mass Flow Meter

How it Works

- FUTEK partners with several manufacturers of control devices to design and develop OEM load cells to constantly measure the flow of particles.

- FUTEK's LSM Series are side mounting load cells proficient at both tension and compression measurements with built-in overload protection.

- This application concept illustrates the LSM Load Cell attached to a counterbalance assembly, in which the force sensing point engages with the surface of the pan.

- The measurement output can be taken to either an amplifier, a digital display, or streamed via USB technology.

- Both the digital display or USB route allow operators the additional use of FUTEK's SENSIT™ Test and Measurement Software, in which they can live graph and data log results.

|

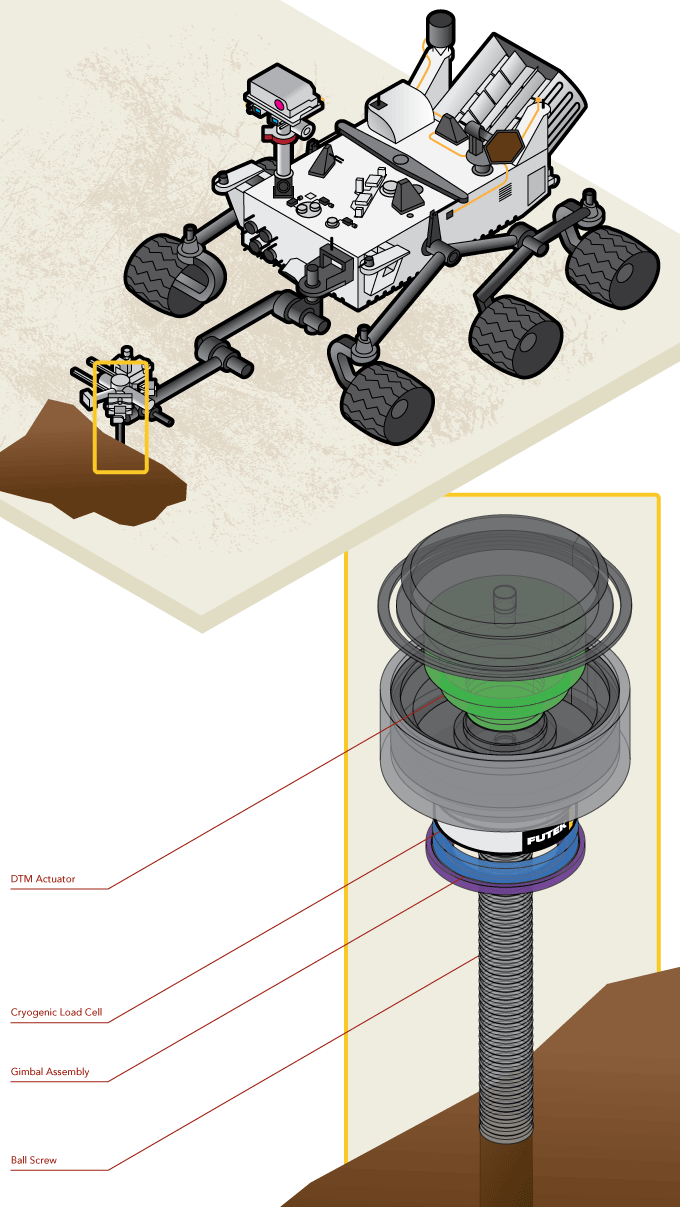

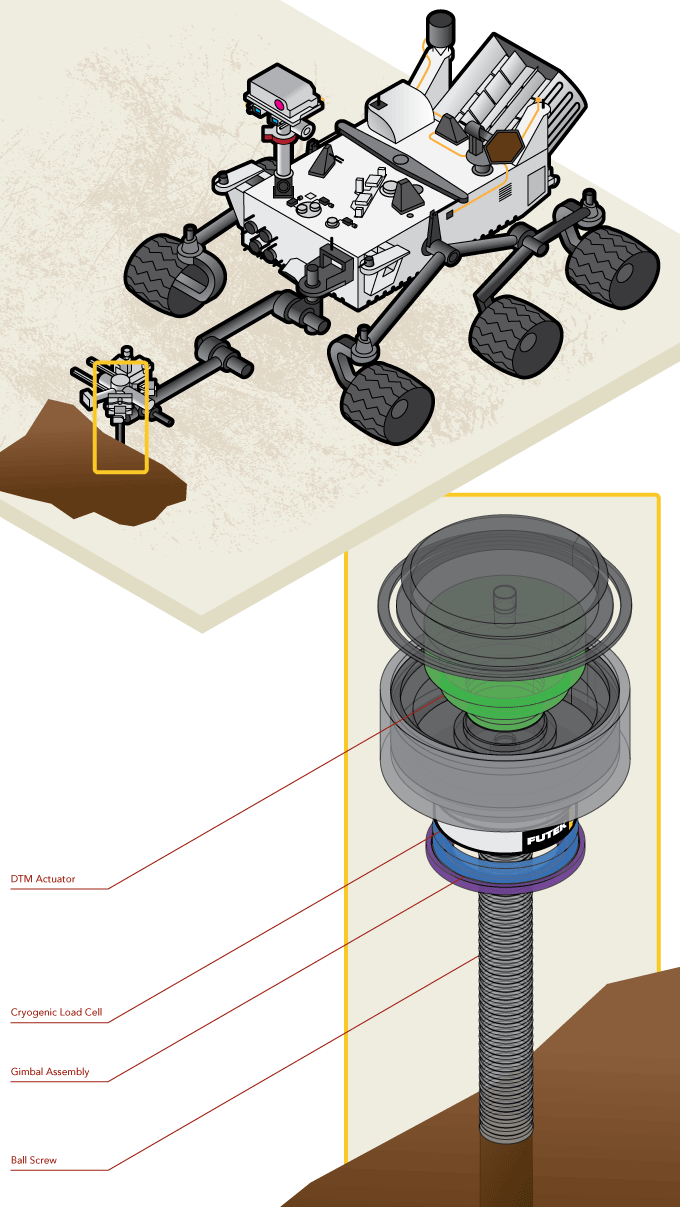

MSL Mars Rover Cryogenic Load Cell

How it Works

- Many applications require customized solutions. Thus, FUTEK knows that when NASA approaches us, a standard off-the-shelf product won't fully fit their bill of requirements. But being that we are in the business of providing solutions, if there's a will there's a way for FUTEK to design and develop the necessary sensor needed for the job. And that's exactly what we did.

- For the MSL Mars Rover Curiosity mission, FUTEK was commissioned by NASA JPL to develop a space/flight qualified cryogenic dual-bridge Thru-Hole Load Cell. This specific sensor sits within the drilling mechanism on the rover. It is responsible to measure the forces of the drill bit at a high level of accuracy and resolution that a current controlled motor drive system cannot achieve. The inclusion of a dual-bridge was a necessity to allow redundancy in the system, which reduces risk of the system becoming inoperable in the extreme conditions.

- If you have a custom application in need of a sensor solution, please visit our Custom Sensor Solution Page to learn more about FUTEK’s capabilities.

|

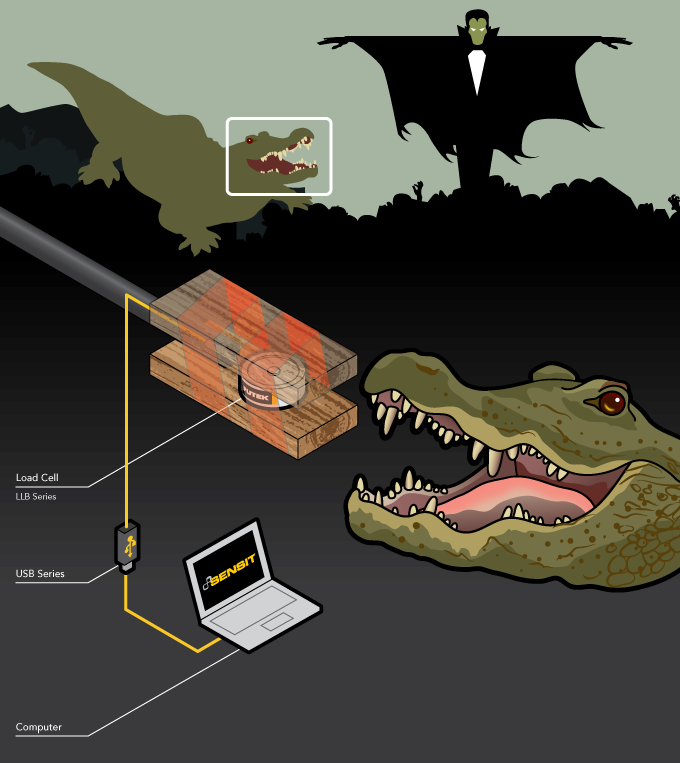

Vampire Bite Force

How it Works

- Pairing the FUTEK LLB450 with our USB Solution and SENSIT™ Test and Measurement Software, the Deadliest Warrior experts were able to instantaneously measure/view the force applied by the alligator.

- In an attempt to bring a source seemingly comparable to that of a vampire, Deadliest Warrior called upon the assistance of a four-legged friend: an alligator.

- Determined to have a strikingly proportionate jaw strength resemblance, the Deadliest Warrior crew taunted our reptile ally with a planked rod enclosing a LLB450 - a miniature 5,000 lb. capacity load button load cell.

- With sheer grit, the alligator chomped down onto this apparatus with a recorded force of 1,723 lb.

|

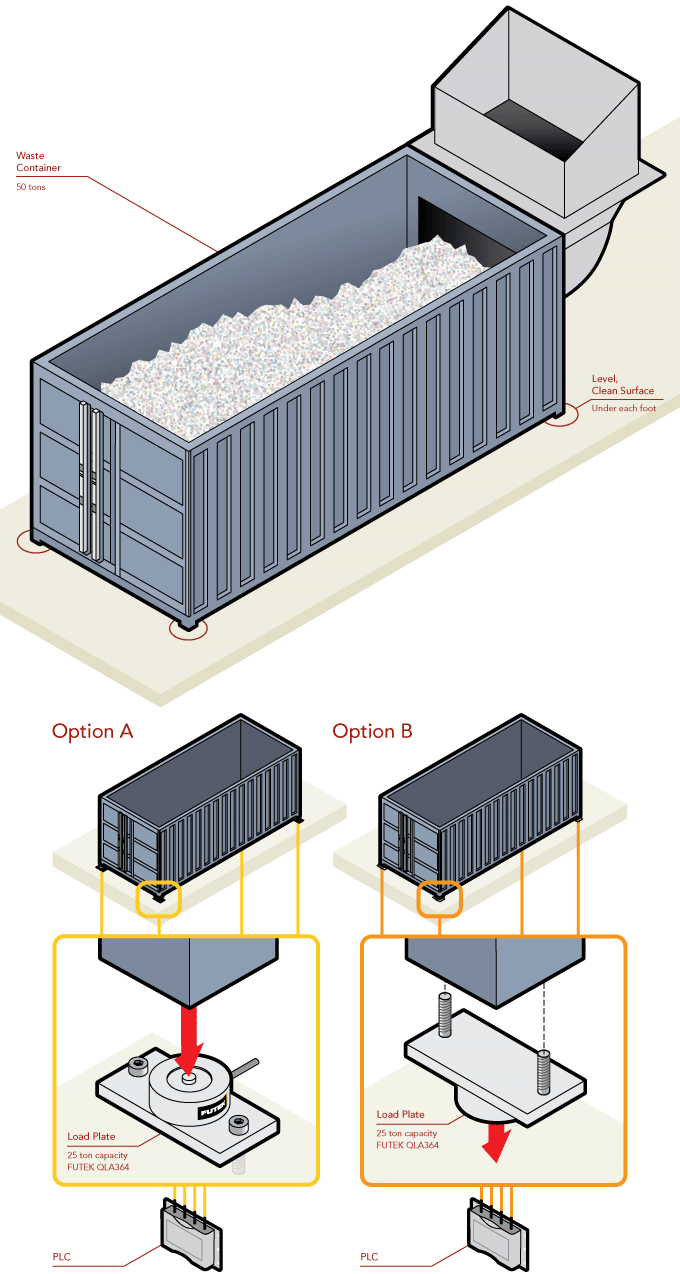

Waste Management Load Measurement

How it Works

- Industrial sized waste containers are able to hold 50 tons. Disposal of the contents only occurs once the container itself has reached its maximum capacity.

- Installing load cells at the base of the container monitors the increases in the capacity of the container.

- In this specific application scenario, four 25 ton load plates have to be mounted to the base of each leg of the container via two mounting options.

- The first mounting option is to mount the load button atop a load plate to a clean, level surface upon which the container will sit. The second mounting option is to mount the load button atop a load plate under each foot of the container.

- Through which ever loading methodology, the data collected by each load cell can be streamed through a summing junction box to a digital display or directly to a PC.

|

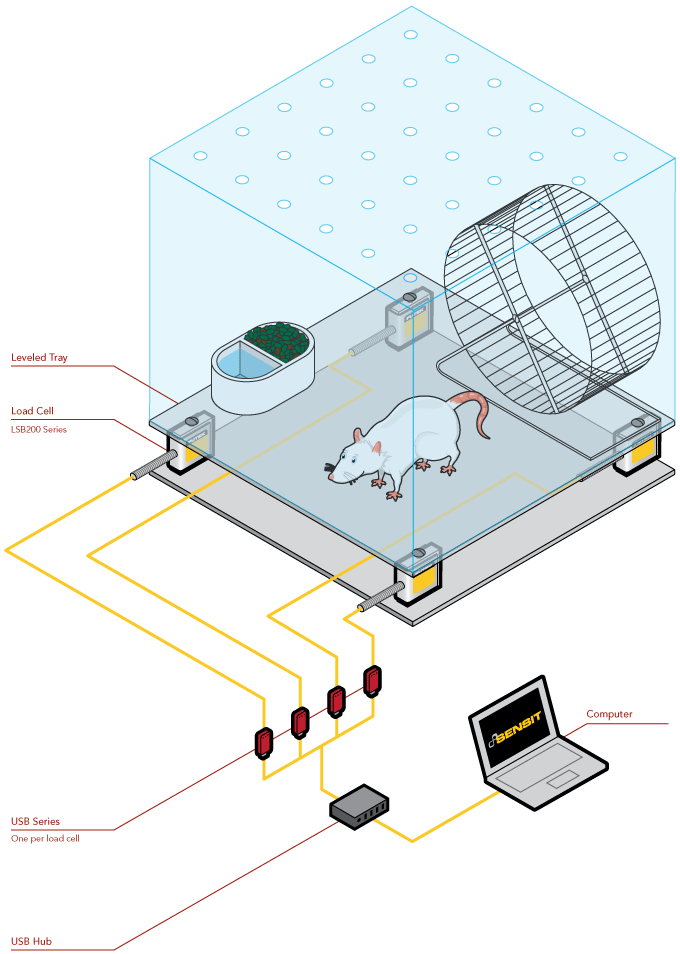

Test Subject Behavioral Phenotyping

How it Works

- Home cage environment systems for behavioral phenotyping demand precise and reliable measurement instruments.

- Precise spatial measurement of home cage behavior is necessary in order to evaluate different products including large scale pharmaceutical designs and genetic lesion programs.

- Installed at all four corners of the home cage, FUTEK's LSB200 will measure the behavioral patterns of the subject as it undergoes testing.

- As the test subject moves throughout the cage, the LSB200s will stream the load forces produced to individual USB Modules.

- SENSIT™ Test and Measurement Software data logs these results on four different channels.

- Researchers can then compare the results of each load cell and effectively gauge the behavioral patterns of the subject.

|

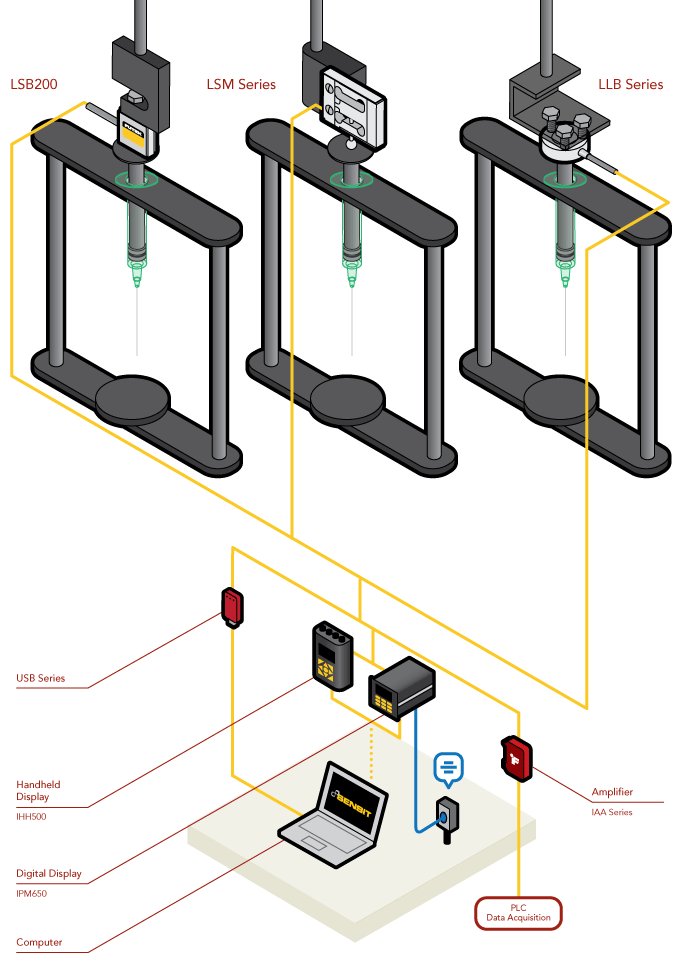

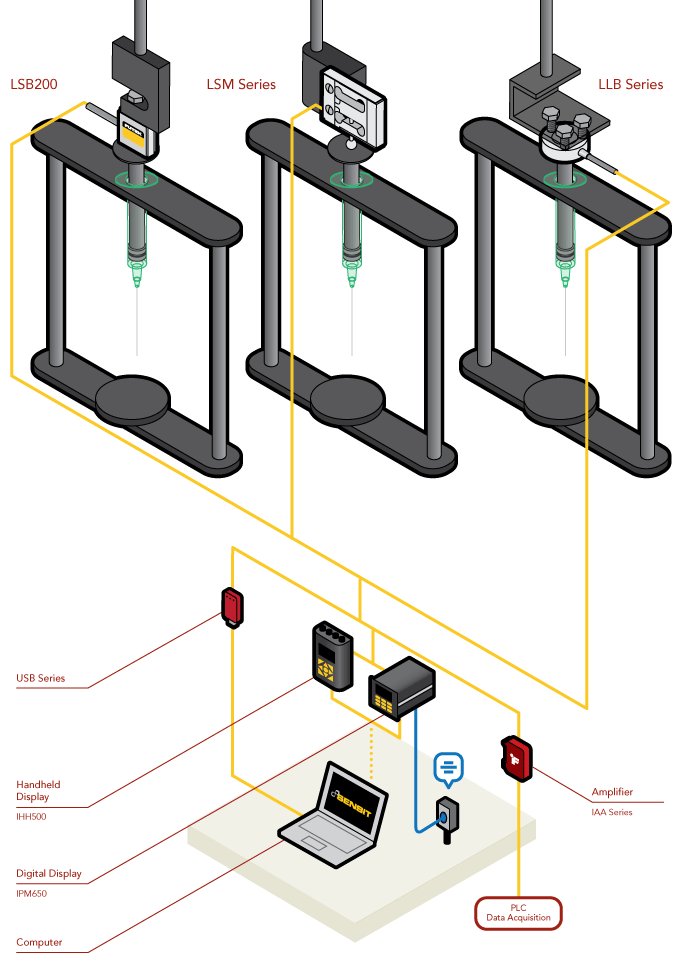

OEM Test Stand

How it Works

- In delicate application such as this, it becomes vital to perform accurate quality audits on equipment used in health-care practices. Therefore, utilizing OEM load cells to audit syringes (infusion pumps) provides medical quality inspectors with assurance that these apparatuses will perform up to code.

- Mounted to a mechanical lever, one of FUTEK's LSB200, LSM Series, or LLB Series load cells will measure the force applied to the syringe pump as it dispenses fluid. Product versatility allows for technicians to select the sensor that works best within their required test environment.

- Each of these measurements can be taken to a number of instruments for evaluation. They can be amplified and taken to a PLC using an IAA Series Analog Amplifier. Alternatively, they can be interpreted by either of FUTEK's digital displays, or streamed via FUTEK's USB Solutions.

- Executing SENSIT™ Test and Measurement Software alongside these digital displays or USB Solutions allows the quality inspector to data log these results. Furthermore, SENSIT™ enables technicians to analyze displacement vs force.

|