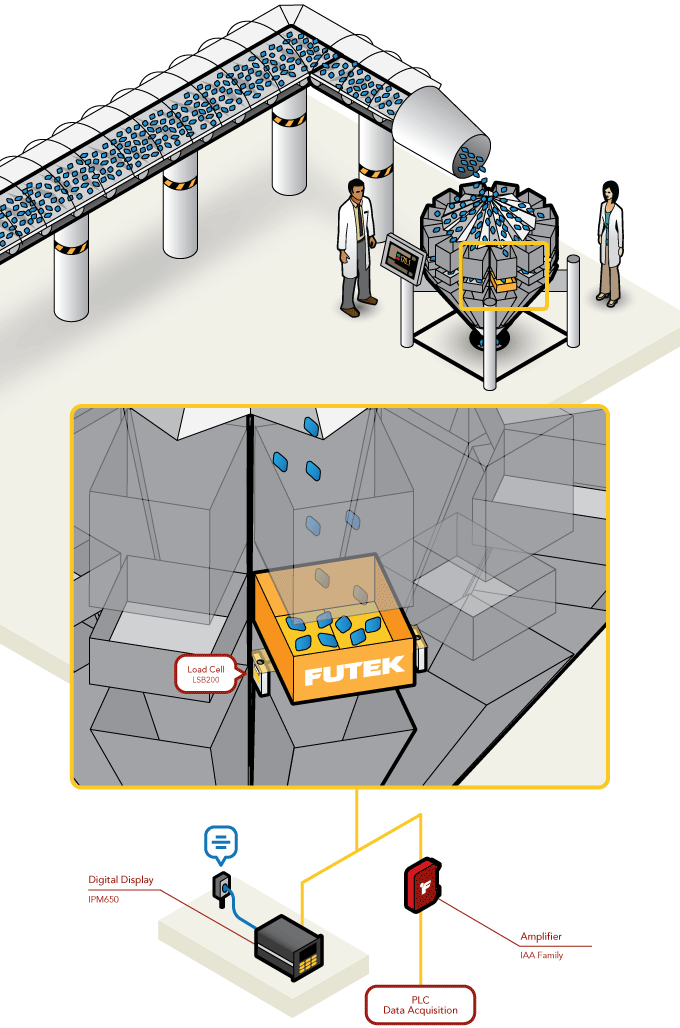

Multihead Weigher

How it Works

- Whether it is in the food or pharmaceutical packaging industry, conveyor belts are used to transport the product from one process to another. At some point, the product itself must be sorted, measured, or verified.

- Therefore, a conveyor will dispense the product into a machine known as a multihead weigher. This weigher is responsible for distributing equal parts per packaged unit.

- In this specific application, FUTEK has attached two LSB200 Jr. Miniature S-Beam Load Cells to each dispenser shaft. The LSB200, which is equipped with built-in overload protection, will measure the content’s load.

- Once the load is at the set package weight, the shutter doors will be triggered to open; thus, releasing the contents into its package container.

|

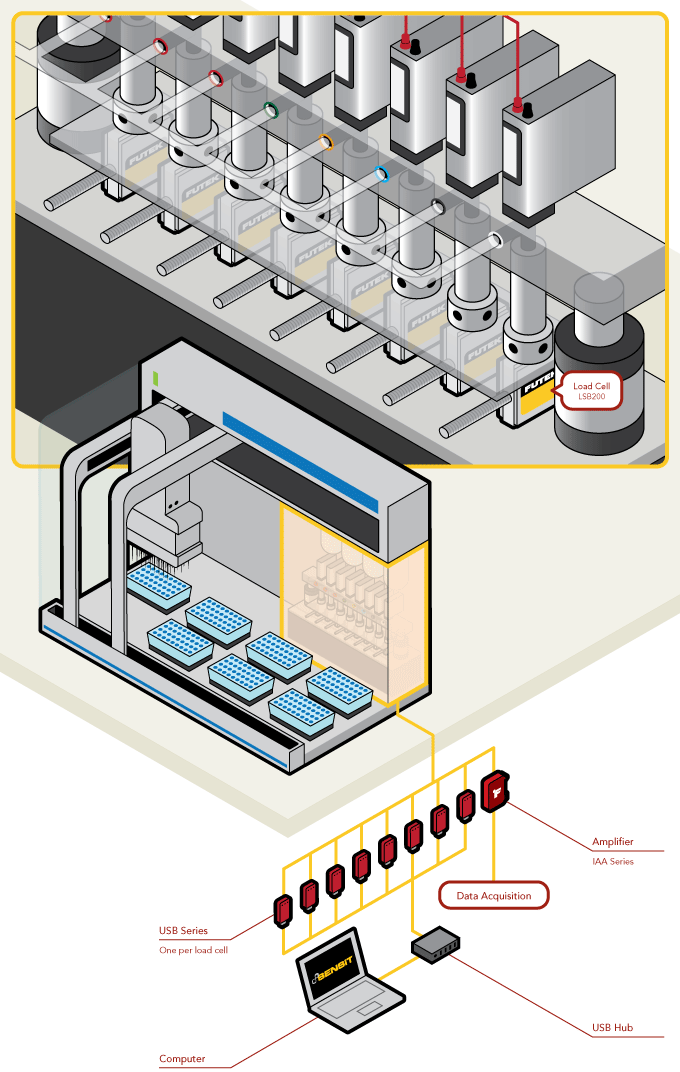

DNA Synthesis

How it Works

- For this application, it is imperative that each dispenser releases an exact amount of fluid for the DNA sequence to be accurate. To ensure this, FUTEK’s LSB200 Jr. Miniature S-Beam Load Cells have been mounted to the base of each fluid dispenser.

- Each LSB200 can measure down to the microgram the fluid as it exits its dispensing tube. These microgram measurements require the use of SENSIT™ Test and Measurement Software alongside FUTEK's USB Solutions.

- Once the allotted amount of fluid has been released from the dispenser, the valve will close until it is time to perform another DNA sequence.

|

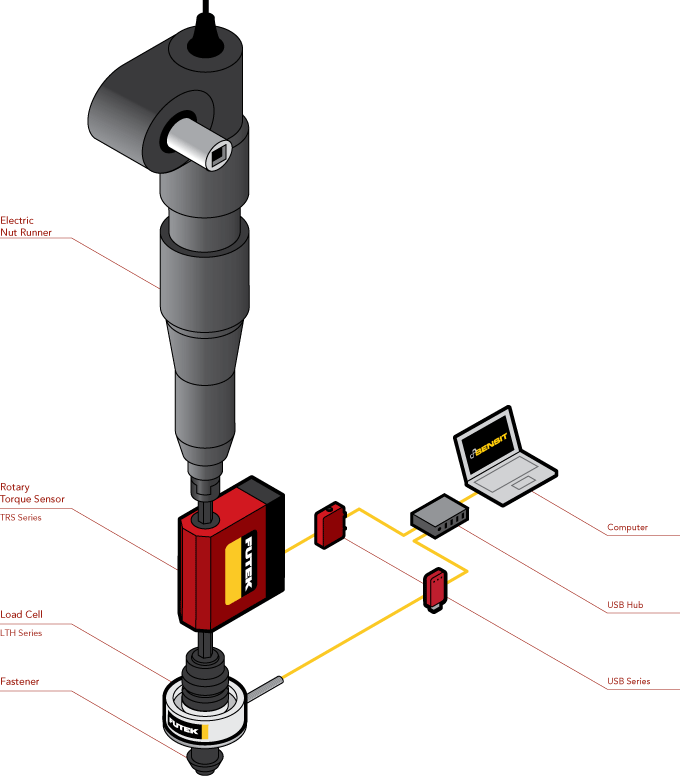

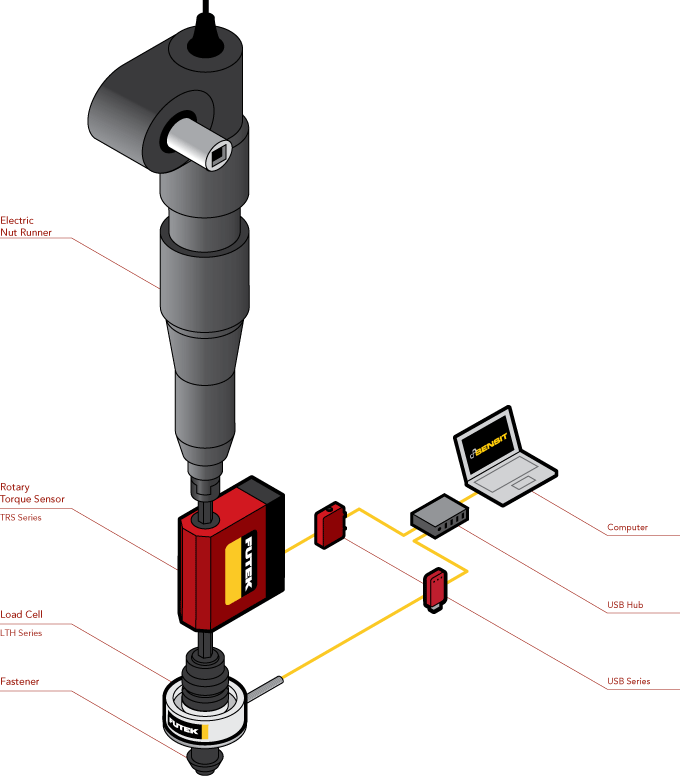

Nut Runner Force/Torque

How it Works

- A standard Donut/Thru Hole Load Cell is used on a bolt and nut assembly, similar to our bolt-fastening application scenario.

- Additionally, a rotary torque sensor is used to measure the torque that is also applied by the electric nut runner within the assembly.

- To monitor each sensors measurements, operators can pair the Donut/Thru Hole Load Cell and Rotary Torque Sensor with FUTEK's USB Solutions.

- Utilizing FUTEK's SENSIT™ Test and Measurement Software alongside the USB520 External USB Kit (mV/V, amplified and encoder input) will allow operators the ability to capture, live graph and interpret the data.

- The USB520 is the ideal data exchange solution for systems that require translation of rotary torque encoder readings, such as angle and speed. Its compact and robust design also makes the USB520 fitting for this type of industrial application.

- Thus, the end user can measure and monitor the thrust using the LTH series. In parallel, the rotary torque sensor will measure the torque, angle, and speed.

|

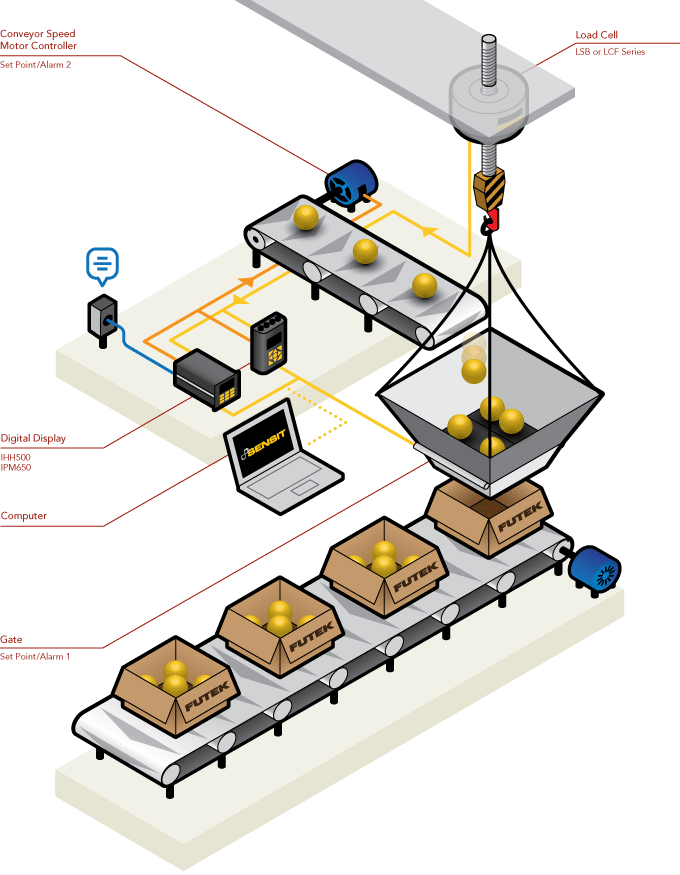

Industrial Automation Container Filling

How it Works

- To ensure equal quantities of a product are distributed into each box, a load cell in conjunction with specific instrumentation has been installed.

- The load cell itself is connected to the hanging distribution container to monitor the weight of each load released into each box.

- Once the upper conveyor belt has dispensed enough product into the distribution container, the instrument connected to the load cell will trigger a relay causing that upper conveyor to stop.

- This then immediately causes another relay to trigger, which releases the gates of the hanging distribution container allowing its contents to fill the box below.

- As soon as the gates of the distribution container close, the upper conveyor resumes motion, allowing for this automation process to begin again.

|

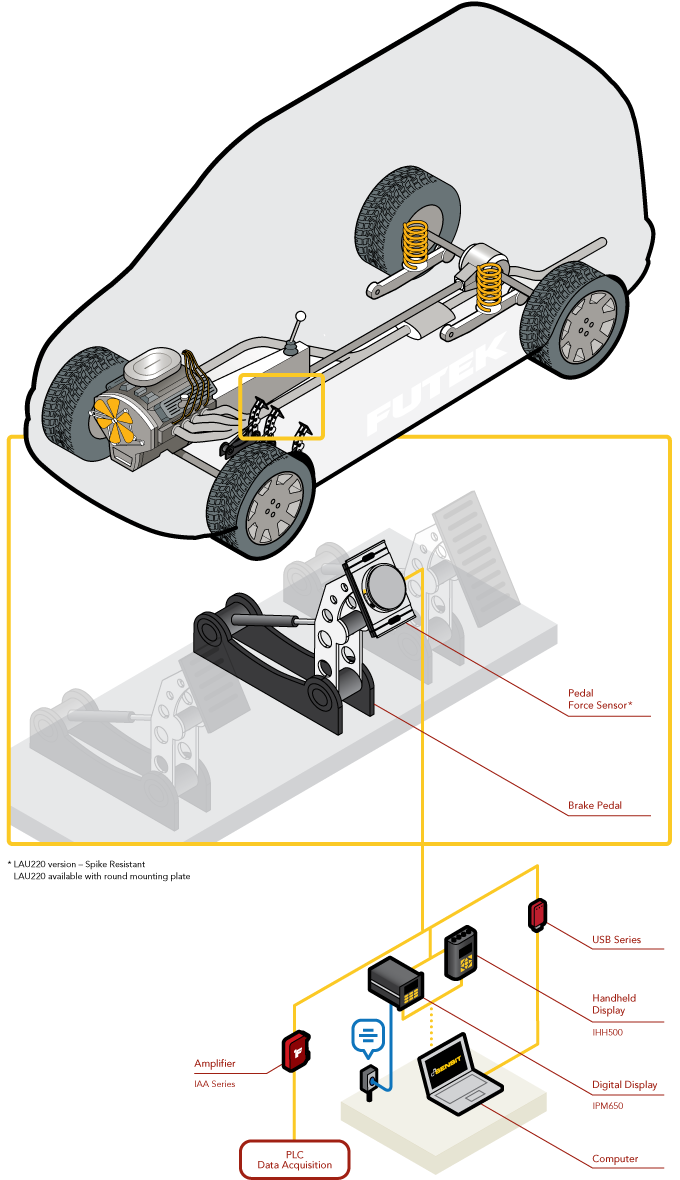

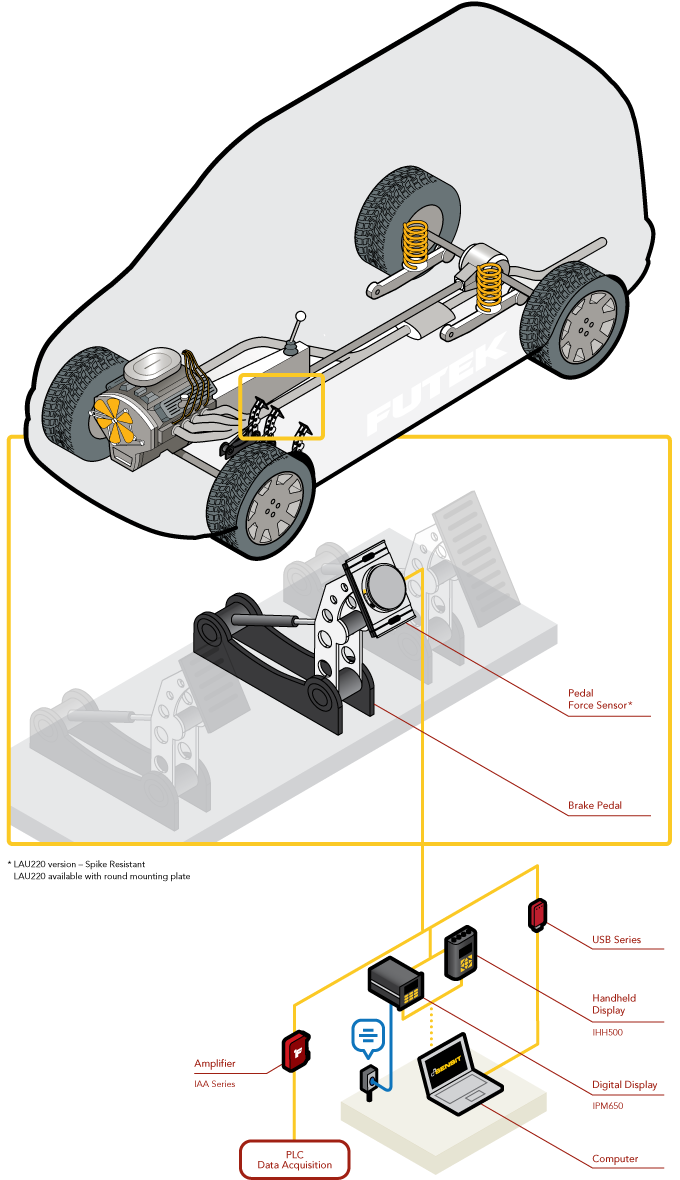

Automotive Pedal Force Testing

How it Works

- Brake system testing is normally carried out during various stages of the manufacturing process. It starts in the initial development stage, followed by endurance, lab and track testing, and continues through the production process for added quality assurance.

- In this particular application, operators may utilize FUTEK's LAU220 Pedal Force Sensor, which is equipped with a mounting plate to ease installation.

- Mounted to the top of the automobile's brake pedal, this pedal force sensor accurately measures and records applied forces during scheduled tests. These tests are carried out to validate the integrity of the brake system.

- The top surface of the sensor is spherical, centralizing the impact force.

- Operators can monitor the data via FUTEK’s IHH500 Intelligent Digital Hand Held Display or IPM650 Panel Mount Display; or it can be streamed to a computer via FUTEK’s USB Solutions.

- The data can then be monitored through FUTEK's SENSIT™ Test and Measurement Software. SENSIT™ can monitor up to 16 channels of measurement readings, as well as live graph and data log.

- This system can also be utilized for accelerator, clutch, and parking brake pedal testing.

|

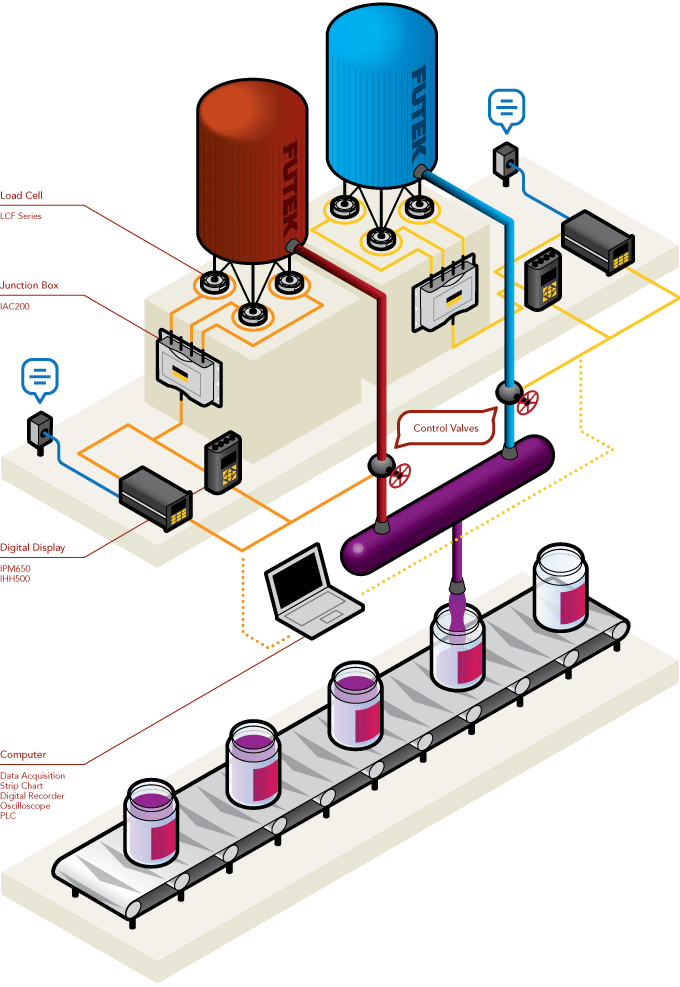

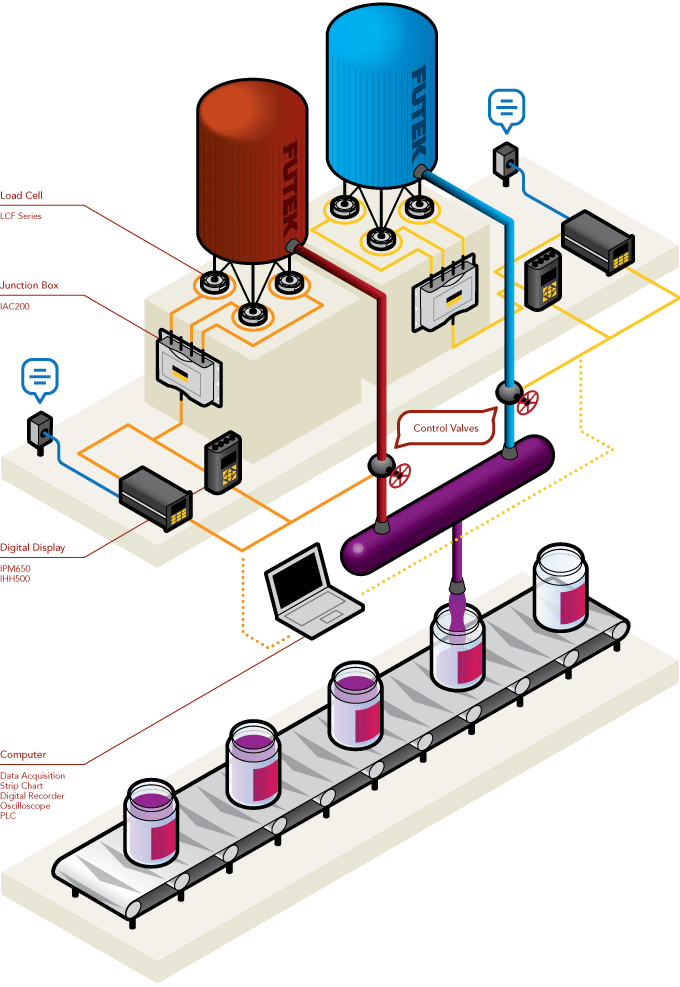

Dual Tank Level Controller

How it Works

- In this particular application, specific ratios of each liquid must be dispensed into mixing container prior to its release into each jar.

- The selection of load cells can vary from pancake type to donut/thru hole or load button depending on the preferred mounting configuration and required precision. Equally important is the selection of electronics to build this platform.

- To ensure that these liquids ratios are exact, several load cells have been installed at the base of each liquid dispensing silo.

- Each silo has been paired with either FUTEK’s IHH500 Intelligent Digital Hand Held Display or IPM650 Panel Mount Display. These instruments will monitor the measurements captured by the load cells.

- In such setups, electronic options such as output options (analog vs. voltage), alarms/relays, and high resolution measurement can ease installation and improve system readings.

- Once a specific ratio of liquid has been released from each silo, the IHH500 or IPM650 will trigger the control valve to close.

- Then the contents in the mixing container can be released into the jar below.

|

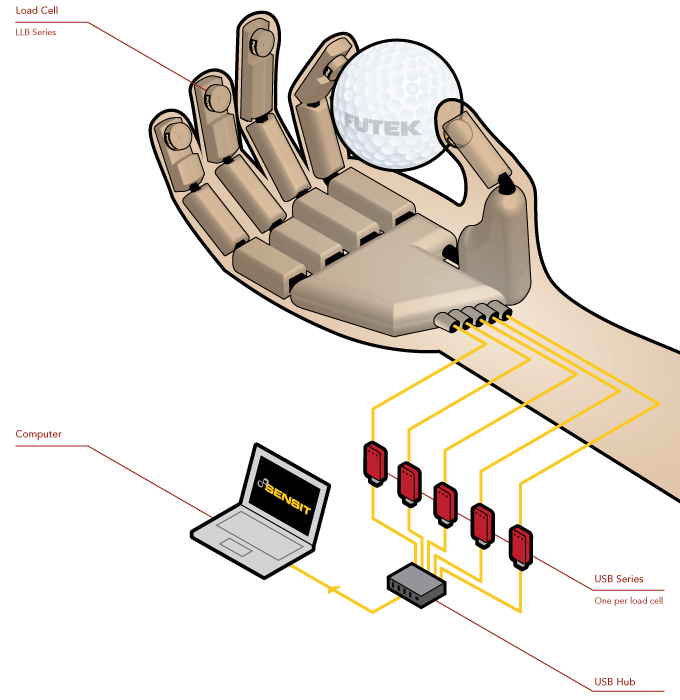

Robotic Tactile Sensing

How it Works

- As research laboratories continue to explore the world of robotics, there exists a greater necessity for high precision test and measurement products.

- This application illustrates five Miniature Load Buttons mounted to the tip of each robotic finger. As the robotic hand manipulates different objects, the force require to handle those particular objects is collected.

- Pairing FUTEK's USB Solution with these Load Buttons, research engineers can stream the multiple force directly onto their PC.

- If their PC utilizes FUTEK's SENSIT™ Test and Measurement Software, the engineers will be able to live graph and log all the data.

|

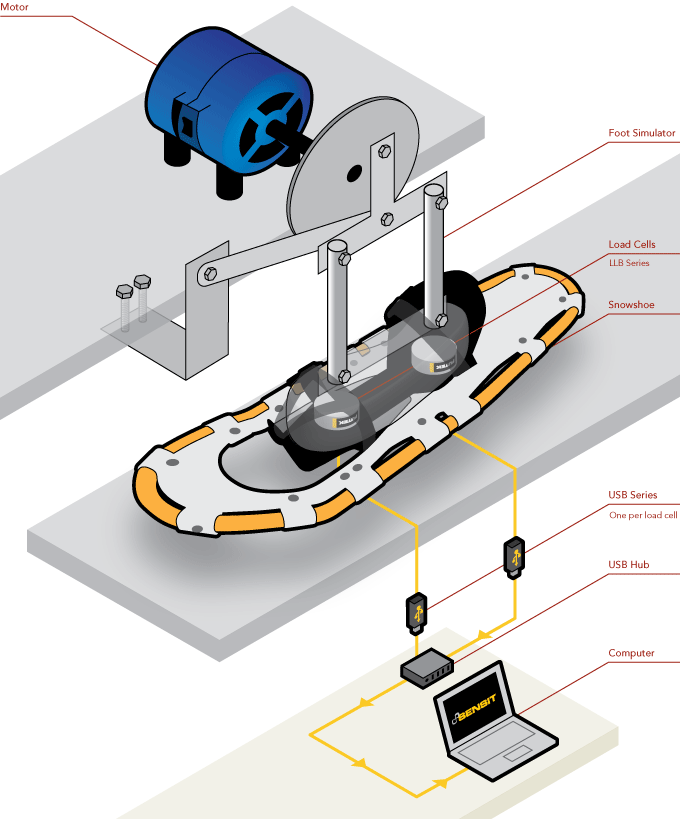

Snow Shoe Testing

How it Works

- In this application, a test stand is used to mimic the movements made during walking. Such tests are very common in commercial product testing to verify product integrity or quality.

- By utilizing a simulation test module, these snow shoes will undergo endurance and durability tests.

- To capture the data results from the aforementioned tests, two load buttons (LLB Series) are placed at the bottom of the foot simulator to measure the force of the heel and toe while in motion.

- Each load cell is paired to a FUTEK USB Solution, allowing the operator to stream the data directly onto his/her PC.

- Using FUTEK's SENSIT™ Test and Measurement Software, the operator then can collect, log, graph, and analyze the results.

|

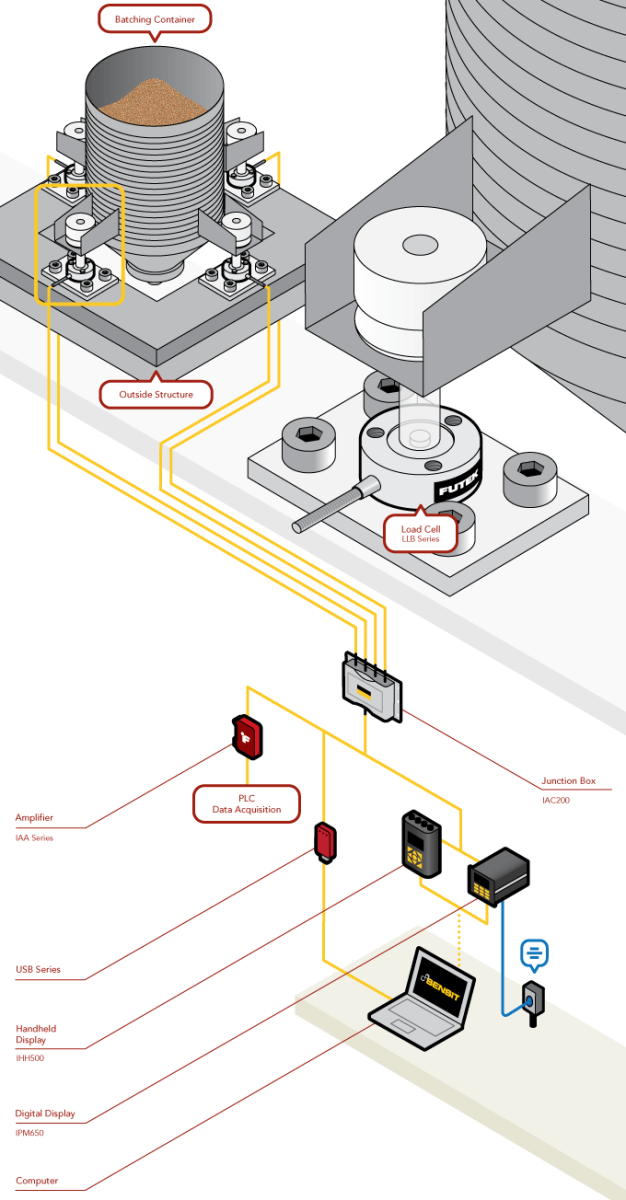

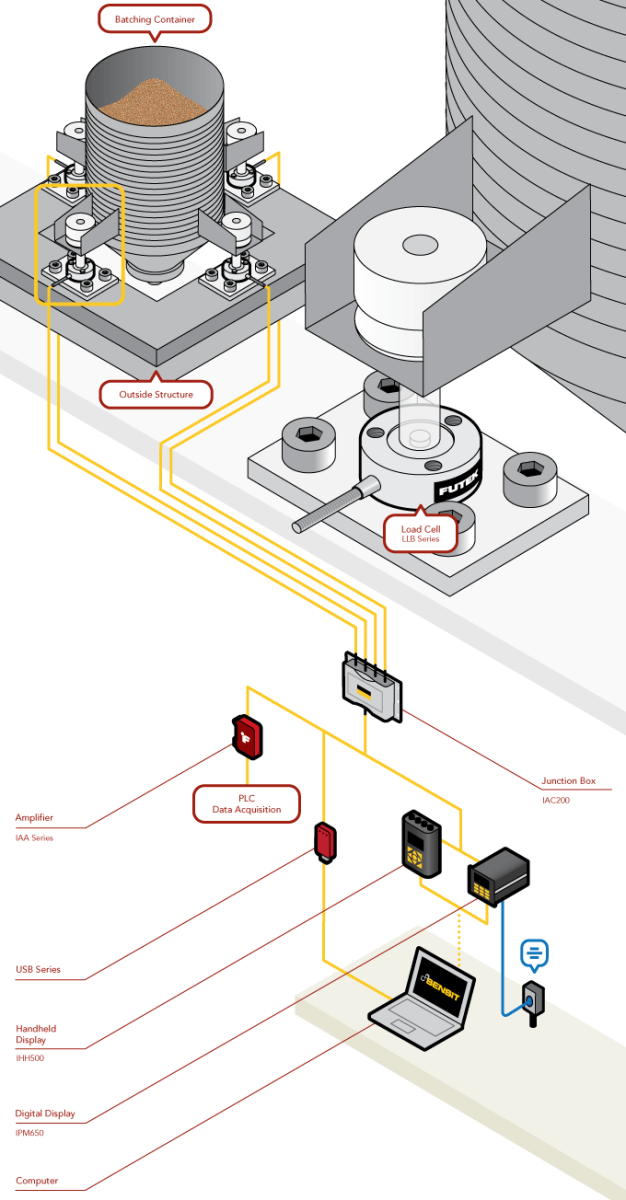

Batch Weighing

How it Works

- Utilizing Load Buttons, the contents of a small-scale silo/industrial container can be monitored.

- Installed at the base of each leg of the container, these compression-based Load Buttons will measure the contents of the container as it increases and decreases.

- As an in-line based load cell, FUTEK's LLB Series requires direct vertical loading on it's loading surface - the button - for precise measurements.

- The data from each load cell can be collected and streamed through a Summing Junction Box, such as FUTEK's IAC200 2–4 Channel Summing Junction Box, to a digital display. Both FUTEK's IPM650 Panel Mount Display and IHH500 Intelligent Digital Hand Held Display are compatible with this testing platform.

- When equipping the platform with either FUTEK's IPM650 or IHH500, Alarms and/or Relays may be utilized to automate the process.

- Operators may also utilize FUTEK's USB Solutions - one USB Module per load cell - to stream the data directly onto a PC.

- FUTEK's SENSIT™ Test and Measurement Software can further the testing platform, allowing the operator the ability to collect and live graph all data.

|

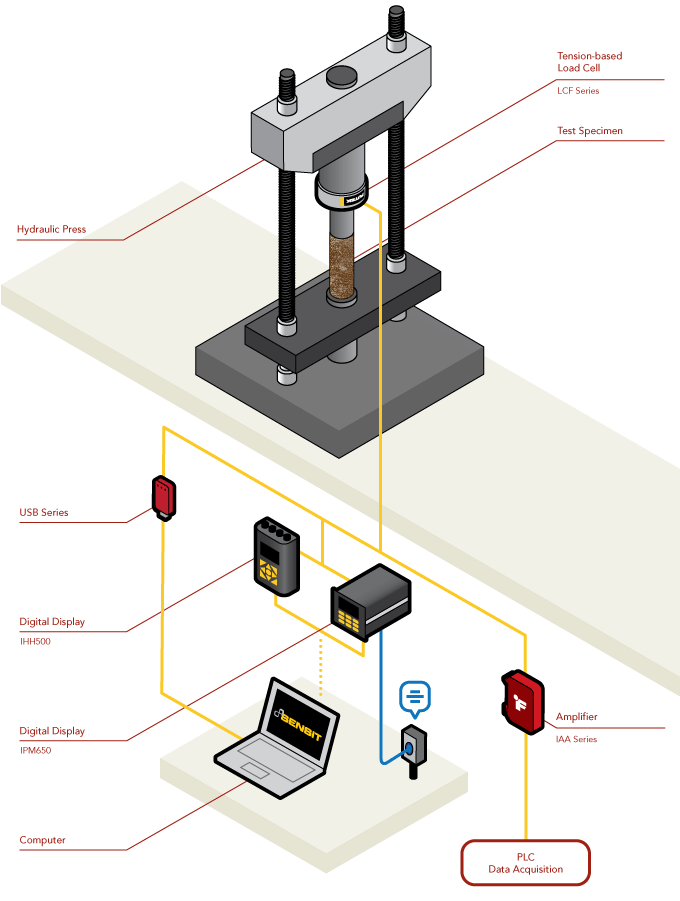

Material Force Testing

How it Works

- Operators have installed a high capacity pancake load cell (LCF Series) into this hydraulic press material test stand.

- Intended for tension-based measurements, the load cell will monitor the force applied to the test specimen - in this case a concrete pillar.

- As the hydraulic press bears down on the concrete pillar, the LCF Load Cell's measure will be streamed to one of three instruments or amplified to a PLC via FUTEK's IAA Strain Gauge Analog Amplifier.

- The LCF Series Load Cell's data can streamed to either of FUTEK's digital displays: the IHH500 Intelligent Digital Hand Held Display or the IPM650 panel mount display, or it can be streamed directly to the operator's PC via FUTEK's USB Solutions.

- Any of these instruments can be paired with FUTEK's SENSIT™ Test and Measurement Software, which can perform data logging, live graphing, and monitoring up to 16 channels.

|