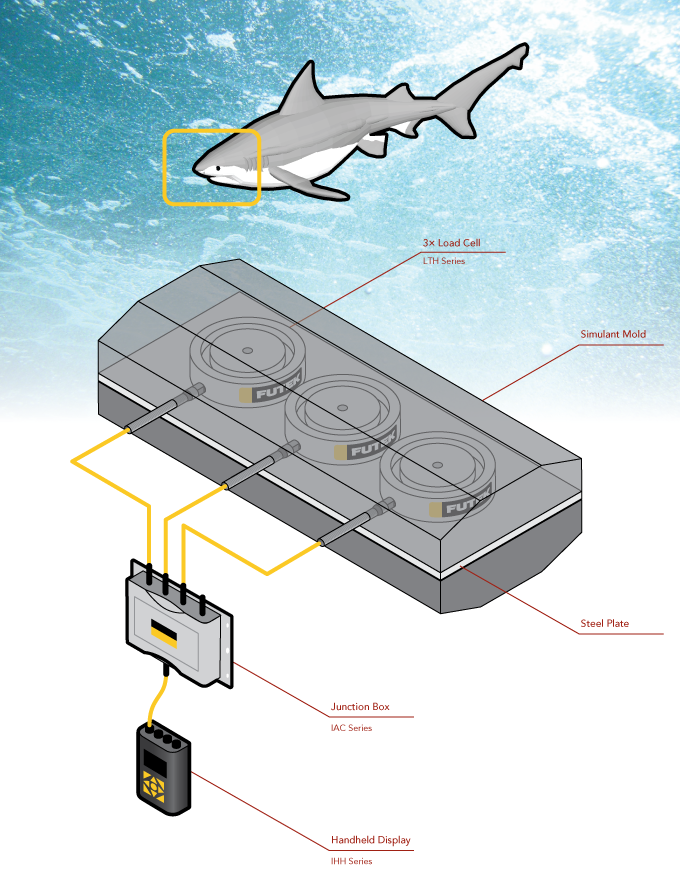

Shark Bite Force Measurement

How it Works

- Using several LTH500 Donut/Through Hole Load Cells, engineers were able to measure the applied force.

- This output was then summed with the IAC200 Summing Junction Box and sent to the IHH500 Digital Hand Held Display where the test engineers monitored and logged all resulting data.

|

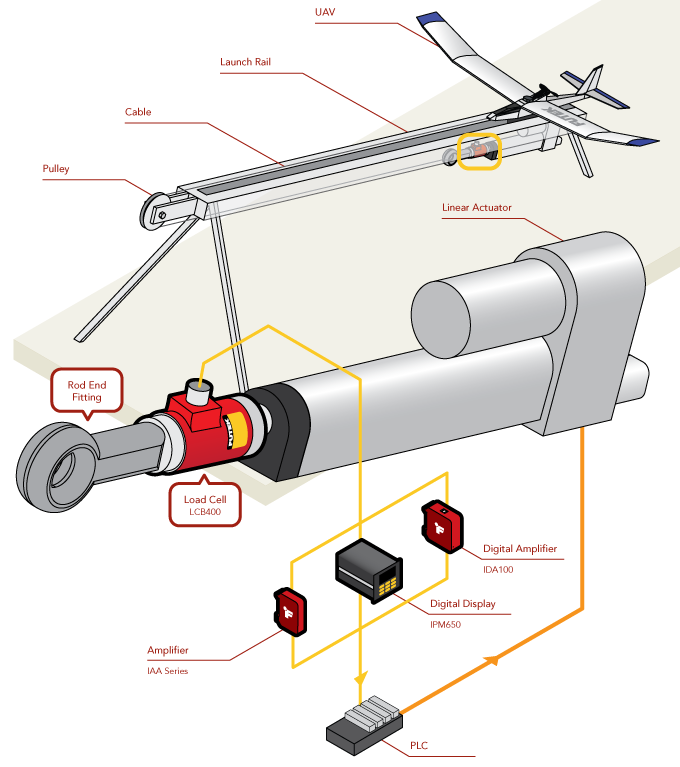

UAV Launcher Force

How it Works

- The fixed end of an LCB400 Rod End Load Cell is mounted to the end of a linear actuator.

- The active end of the LCB400 is then attached to the cable that will pull the UAV.

- The actuator piston is then rapidly retracted, pulling the cable that will launch the aircraft into the air.

- The LCB400 measures the force applied to the cable by the actuator.

- The measurement from the LCB400 is sent to the digital display (IHH500, IPM650) or displayed on a PC with our SENSIT software(IDA100)

- An amplified analog signal is then sent to the PLC controlling launcher and enabling force control.

- Additionally, our SENSIT software can be used to log sensor output for our IPM650 and IDA100.

|

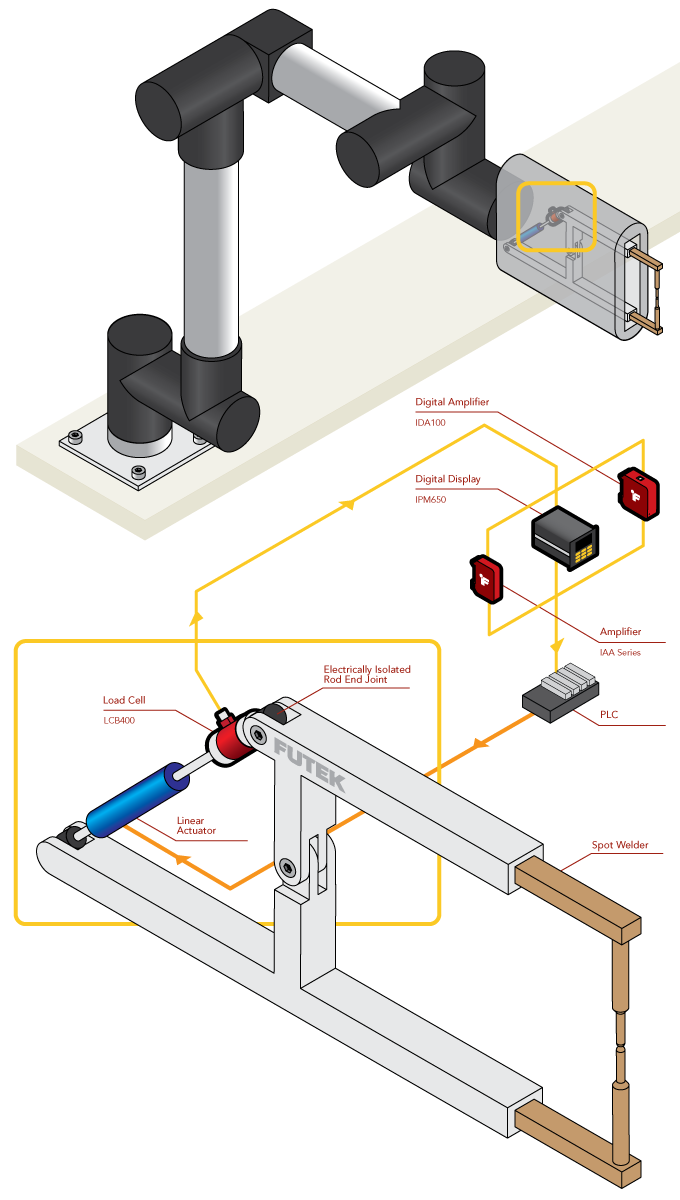

Robotic Spot Welding Force

How it Works

- An LCB400 Rod End Load Cell is installed in line with the actuator controlling the spot welding tongs.

- As the actuator closes the tongs around a part, the LCB400 measures the force applied onto the part.

- The measurement from the LCB400 is then sent to the IAA series or IDA100 Strain Gauge Analog Amplifiers.

- An amplified analog signal is then sent to the PLC controlling the spot welding tongs enabling clamp force control.

- Additionally, our SENSIT software can be used to log sensor output for quality control purposes from the IDA100.

|

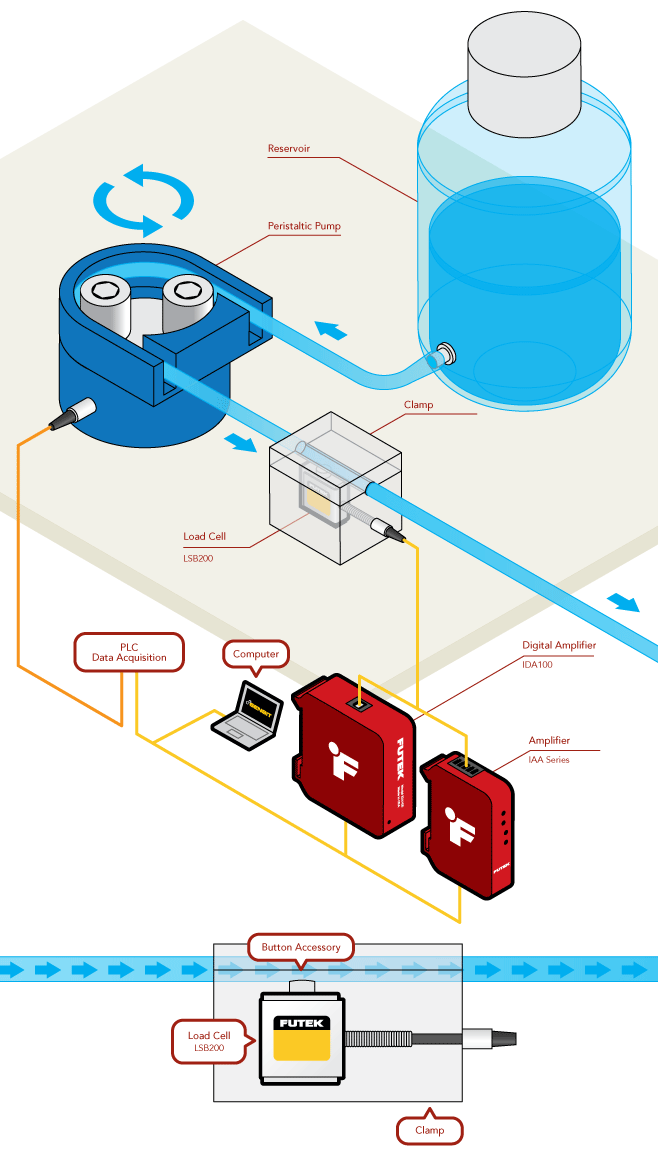

Fluid Flow Rate Measurement

How it Works

- An artificial restriction (occlusion) is placed at the desired point using a clamp.

- One end of the clamp has FUTEK's LSB200 mounted between the clamp and the mount point.

- By creating an artificial flow restriction (an occlusion), the fluid exerts an increased force onto the tubing.

- The LSB200 measures the force applied to the occlusion by the fluid which can be correlated to fluid flow rate.

- The LSB200 was chosen to provide a high accuracy and linearity force measurement with significant overload protection.

- FUTEK's IAA and IDA100 amplify and transmit the load cell signal to the system PLC for flow measurement.

- Additionally, the IDA100 enables logging and monitoring of the load cell output via a PC with FUTEK's SENSIT software.

|

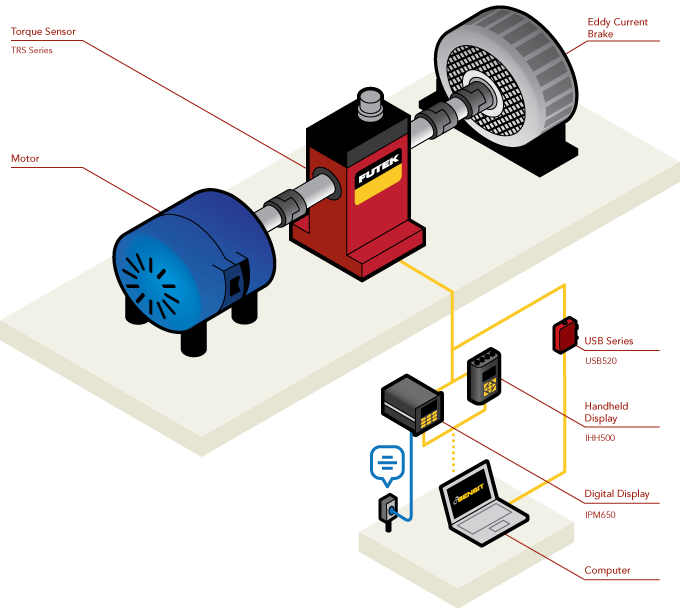

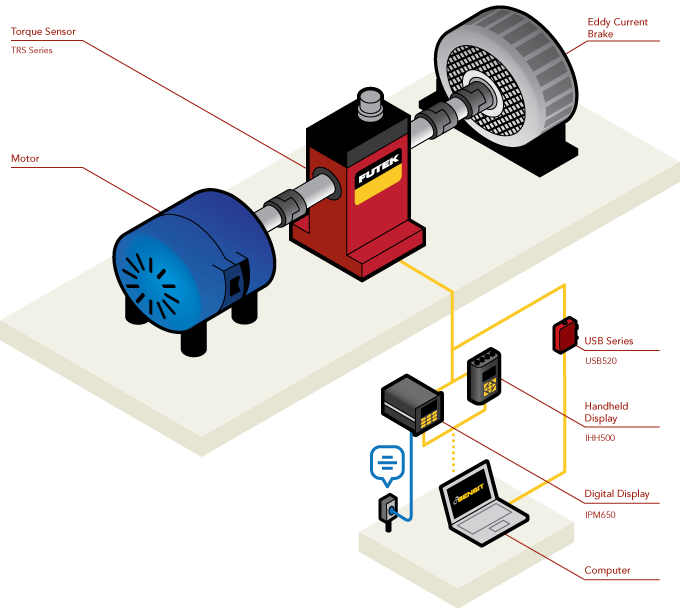

Torque/Motor Test Stand

How it Works

- FUTEK's TRS Series is an effective tool for motor testing/auditing, feedback control, monitoring torque, and analyzing the efficiency of test stands.

- In this application, the TRS Rotary Torque Sensor is coupled between an eddy brake and motor.

- As the motor rotates, the TRS Sensor measures the torque produced between by the motor.

- FUTEK developed certain models of the TRS Series with built-in encoders. These encoders measure the angle/speed produced during this test.

- Torsion measurements can successfully be monitored on a digital display, such as FUTEK's IPM650 Panel Mount Display or IHH500 Intelligent Hand Held Display, or streamed to a PC using FUTEK's USB520.

- The USB520 is the ideal data exchange solution for systems that require translation of rotary torque encoder readings, such as angle and speed. Its compact and robust design also makes the USB520 fitting for this type of industrial application.

- Applying FUTEK's SENSIT™ Test and Measurement Software to this test platform will allow the operator to live graph and data log the results.

|

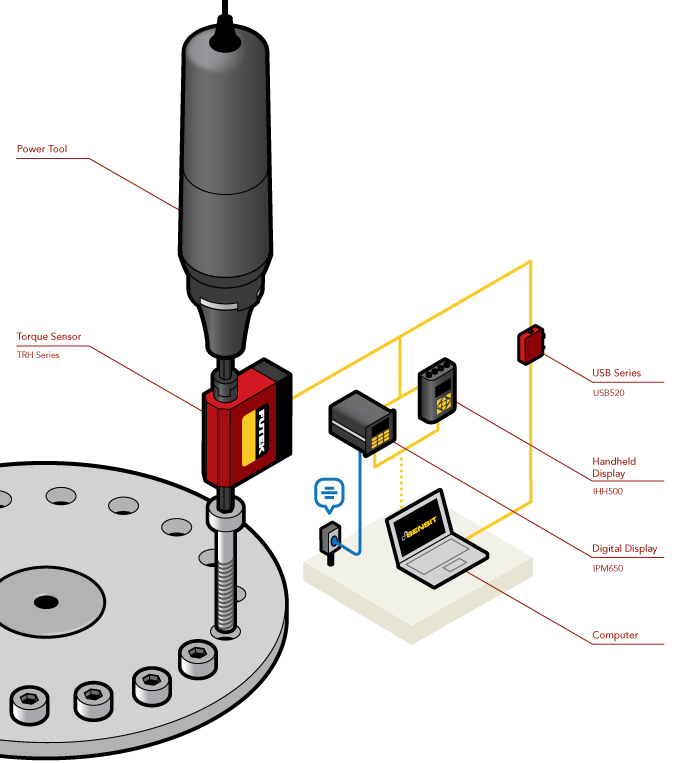

Power Tool Measurement

How it Works

- Under quality assurance standards, rotary torque sensors are used to verify the bolt fastening of power tools and screw spindles.

- In this application, FUTEK’s TRH Hex-Drive Rotary Torque Sensor has been coupled to a power tool to verify its torque and rotational angle as it fastens a bolt into a fixed plate.

- These measurements can be read on either FUTEK's digital displays, the IHH500 or IPM650, or streamed directly to a PC using FUTEK’s USB520.

- The USB520 is the ideal data exchange solution for systems that require translation of rotary torque encoder readings, such as angle and speed. Its compact and robust design also makes the USB520 fitting for this type of industrial application.

- Operators also can utilize FUTEK's SENSIT™ Test and Measurement Software to log and graph all data.

|

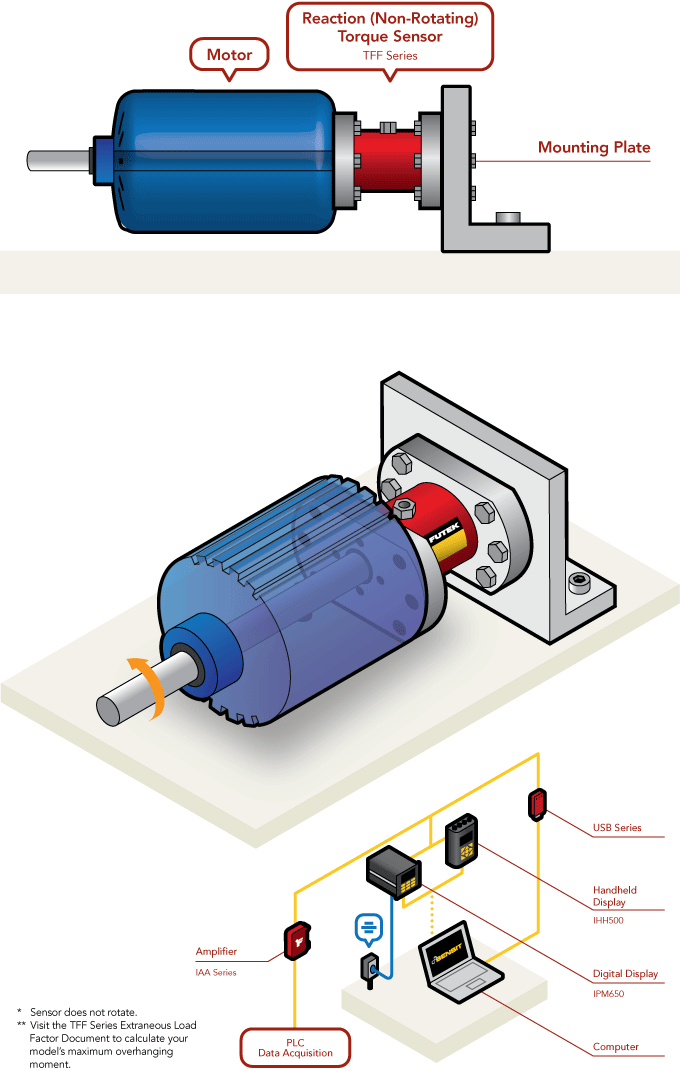

Motor Test Stand

How it Works

- Reaction Torque Sensors can be used to audit rotary torque measurements.

- In this application, a Reaction Torque Sensor is installed between a motor and a fixed plate.

- The TFF Series Reaction Torque Sensor is intended to measure any torsion produced by the motor itself while in operation. This test is also known as measuring torque moments.

- The data produced by this test stand can be viewed on a digital display, such as FUTEK's IHH500 Hand Held Display or IPM650 Panel Mount Display, or streamed directly to a PC using FUTEK's USB Solutions.

- If more detailed data is required, utilizing FUTEK's SENSIT™ Test and Measurement Software allows operators the ability to live graph and log all data collected.

|

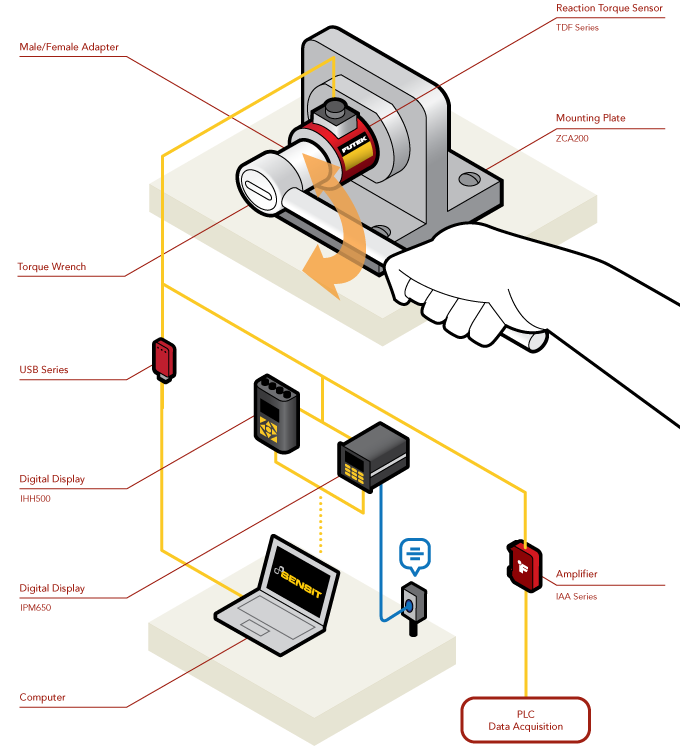

Torque Verification/Calibration

How it Works

- FUTEK’s TDF Series is an efficient tool to use when auditing torque wrenches.

- In this application, the TDF Reaction Torque Sensor is fixed to a mounting plate and coupled to a torque wrench using a male/female adapter.

- As the operator ratchets the torque wrench up and down, FUTEK’s TDF Sensor will measure the torque being applied.

- These measurements are sent directly to a paired instrument. Depending on instrument selection, the operator can either view the data on a digital display or stream the data directly onto a PC.

- If the data shows any anomalies, the torque wrench may be in need of recalibration to meet its intended spec.

|

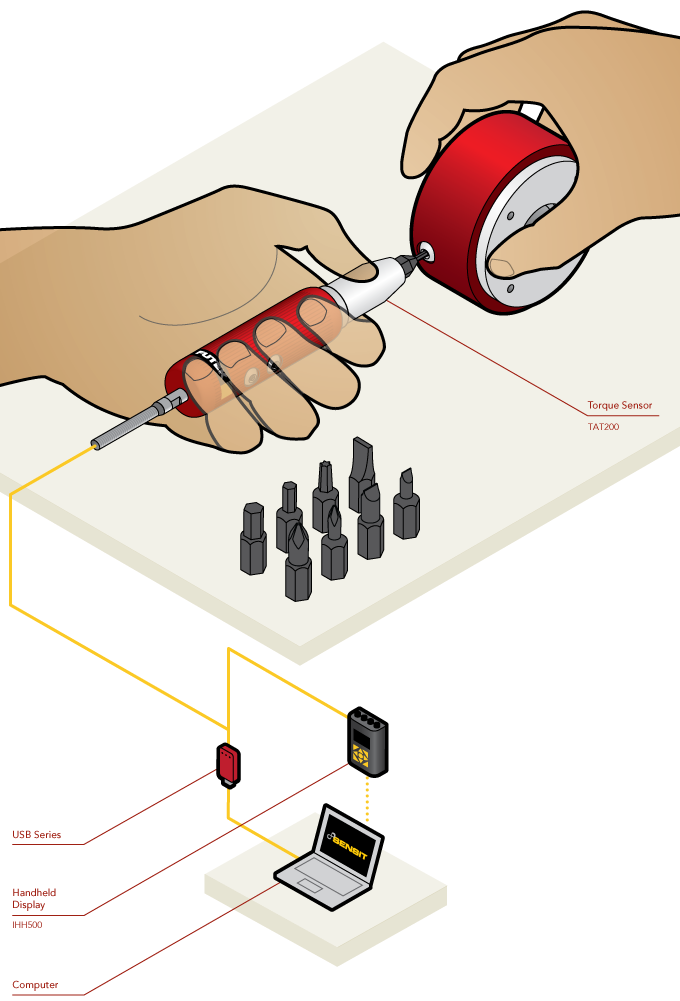

Miniature Torque Screwdriver

How it Works

- During the assembly of more delicate products, operators may be required to use Torque Screwdrivers to monitor the torque applied to nuts and/or bolts.

- FUTEK's Miniature Reaction Torque (TAT200) lends itself as a perfect auditing tool to monitor such torsional measurements.

- Pairing the TAT200 with our USB Solutions and SENSIT™ Software creates the perfect laboratory platform for data logging and live graphing measurements straight onto that operator's computer screen.

- Pairing the TAT200 with our IHH500 Intelligent Digital Hand Held Display lends this tool for more industrial uses, as a production device.

|

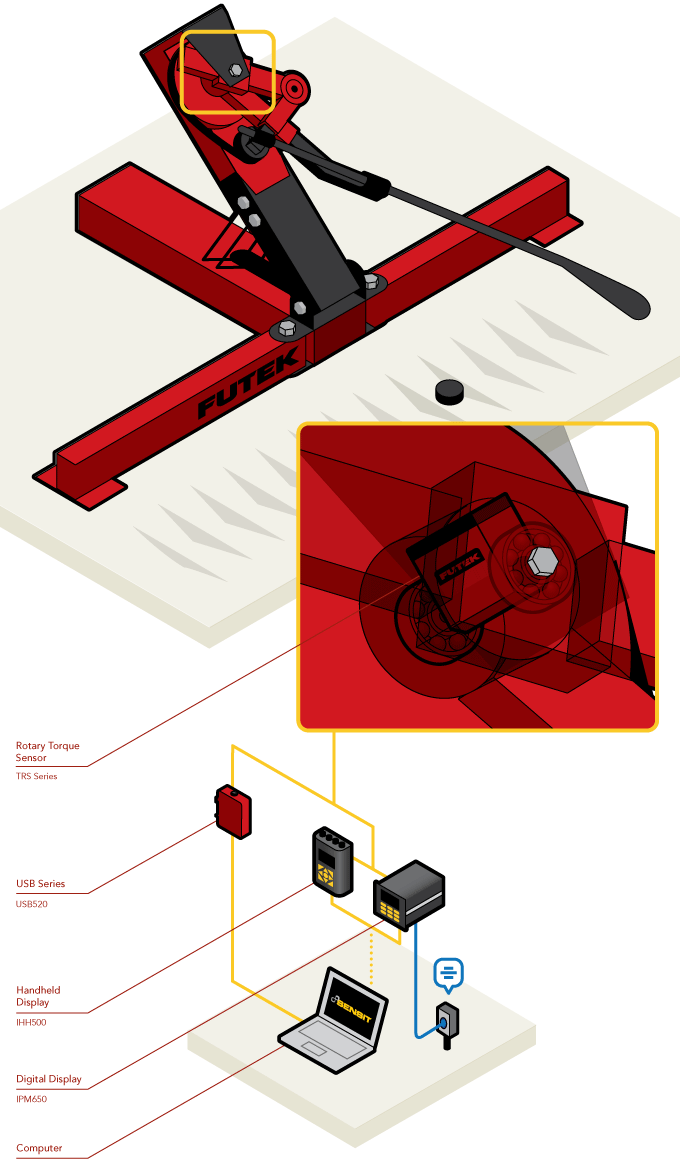

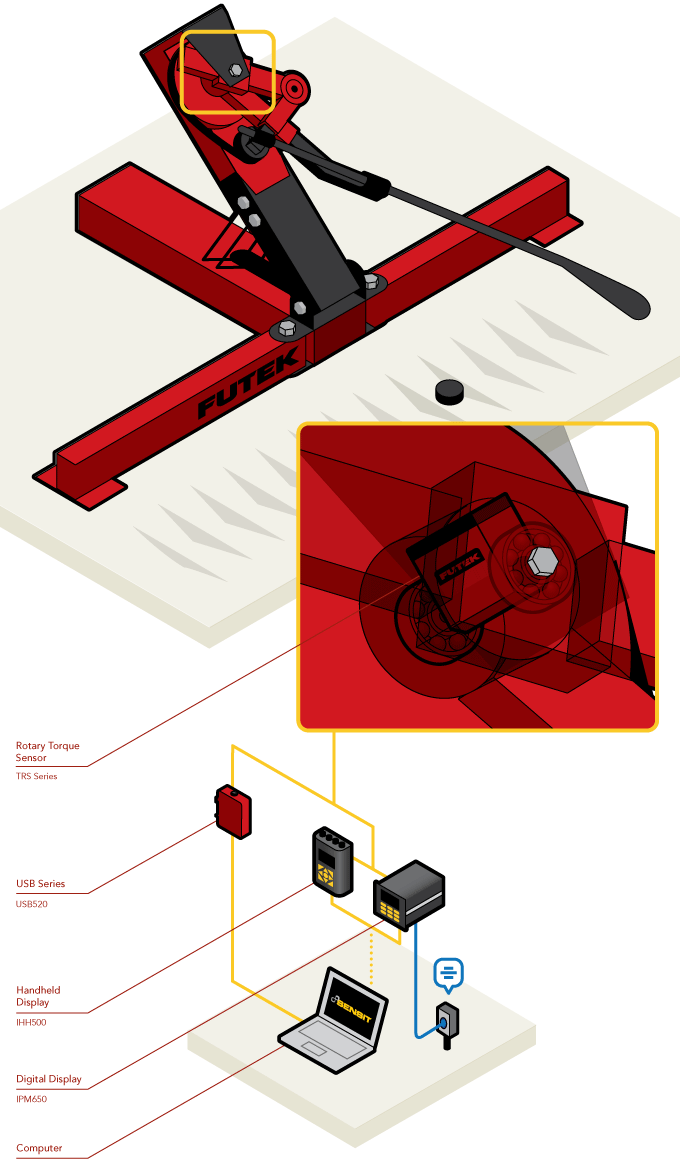

Industrial Robotic Automation

How it Works

- The above application illustrates a commercial test stand for professional-grade hockey sticks.

- Utilizing a Rotary Torque Sensor within the assembly of this robotic automation machine, engineers can measure the breaking point - rotational force - of each slap shot.

- Whether to robotic arm winds to 180 degrees or to a full rotation of 360 degrees, the installed Rotary Torque Sensor will measure the exact torque exerted as the hockey stick strikes the puck.

- This data can be view on a digital display, such as FUTEK's IHH500 Intelligent Digital Hand Held Display or IPM650 Panel Mount Display, or streamed directly to a PC via USB520.

- The USB520 is the ideal data exchange solution for systems that require translation of rotary torque encoder readings, such as angle and speed. Its compact and robust design also makes the USB520 fitting for this type of industrial application.

- If the test engineers wish to collect, graph and interpret these results, they can apply FUTEK's SENSIT™ Test and Measurement Software.

|