|

|

|

|

|

|

|

|

3D laser scanners for inline quality inspection

|

|

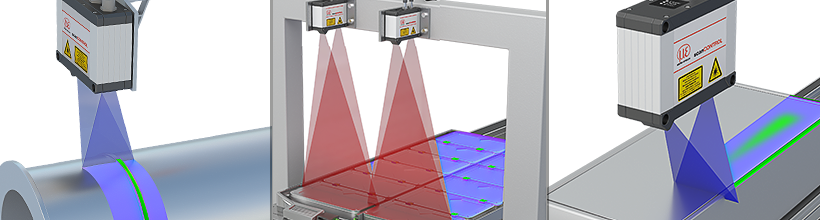

scanCONTROL 3D scanners are used for precise inline 3D measurements in numerous applications. Scans are performed by moving the scanner or the target. Due to their low weight, the scanners are ideally suited both for robotic applications and inline production monitoring. These 3D laser scanners are characterized by high dynamics, absolute precision and their compact size. With the scanCONTROL 3000 and the new scanCONTROL 3002 series, Micro-Epsilon offers a comprehensive portfolio with numerous measurement areas, Red and Blue laser technologies and extensive accessories.

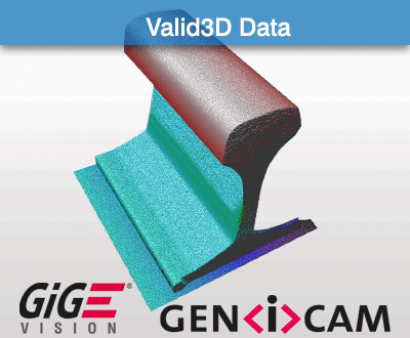

The scanCONTROL 3D laser scanners are based on the latest GigE Vision and GenICam standards and can therefore be integrated into a wide range of image processing environments. The powerful 3DInspect software is available for parameter setting, evaluation and output.

|

|

|

New: scanCONTROL 3D laser scanners

|

|

|

|

|

|

|

3D laser scanners for inline applications

|

|

|

|

|

|

|

The scanCONTROL 3D scanners feature a wide range of different measurement areas from 25 x 15 mm up to 200 x 300 mm. Regardless of the size of the measurement area, these laser scanners impress with fast measurements and high precision at the same time.

The variety of measurement areas allows, on the one hand, both the acquisition of smallest details and structures, and, on the other hand, the measurement of large objects with a large offset distance. For this reason, scanCONTROL 3D scanners are used in various industries.

|

3D scans for integrators and end users

|

|

|

|

|

|

|

|

|

|

|

For the integration into the customer’s environment and image processing programs, the scanCONTROL 3D scanners offer a comprehensive SDK (Software Development Kit) based on the industry standards GigE Vision and GenICam. The unique Valid3D technology enables lossless display and processing of the 3D point clouds. |

|

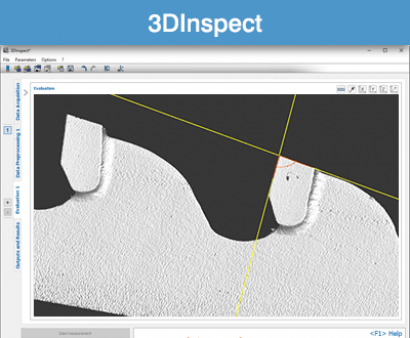

The scanCONTROL 3D scanners can be operated with the powerful 3DInspect software. Numerous tools, automation functions and interfaces enable the creation, processing and output of measured values based on real 3D point clouds.

|

|

|

|

|

|

|

| |

|

|

| |

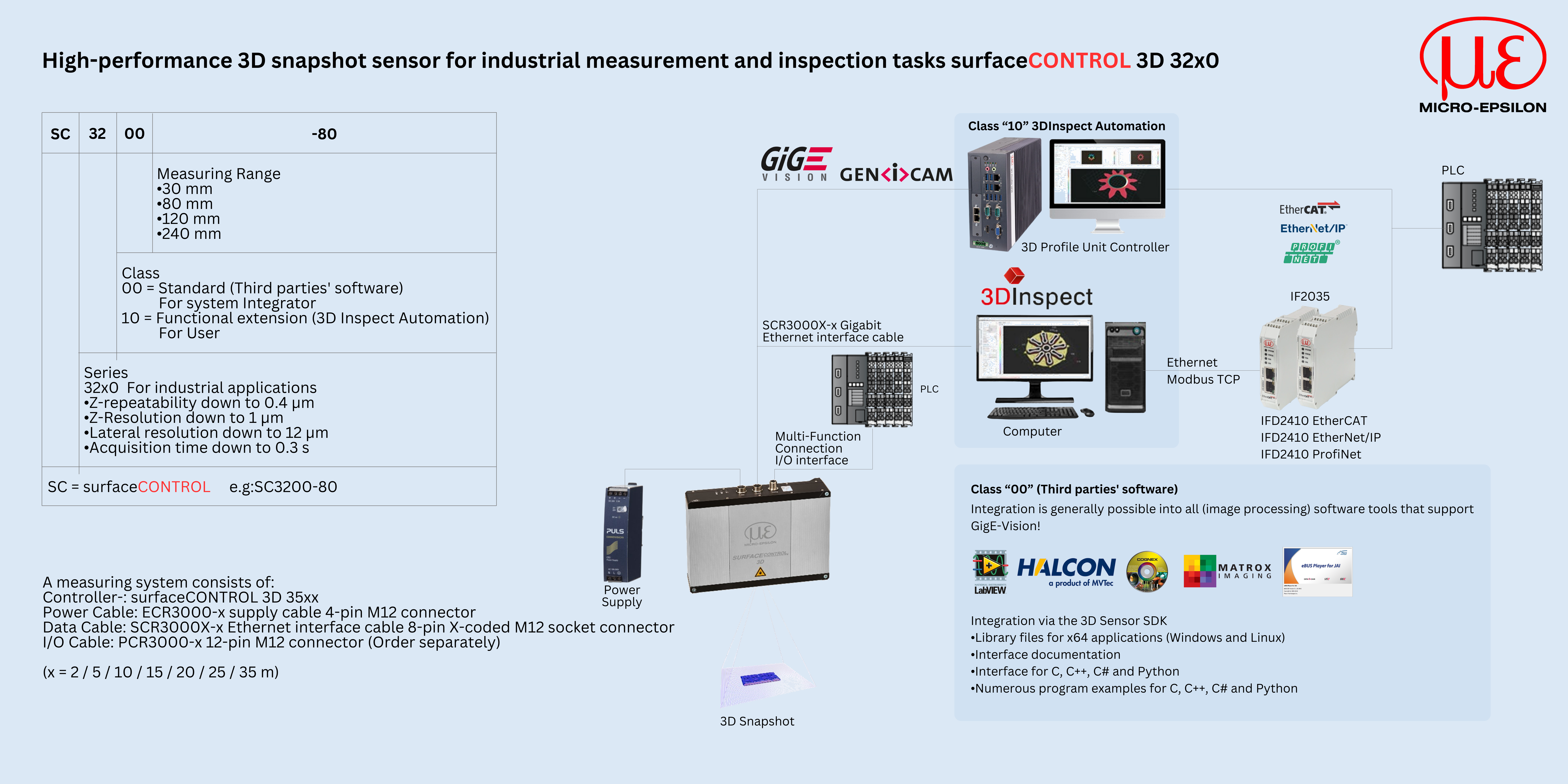

High-performance 3D snapshot sensor for industrial measurement and inspection tasks

|

|

|

|

|

|

|

|

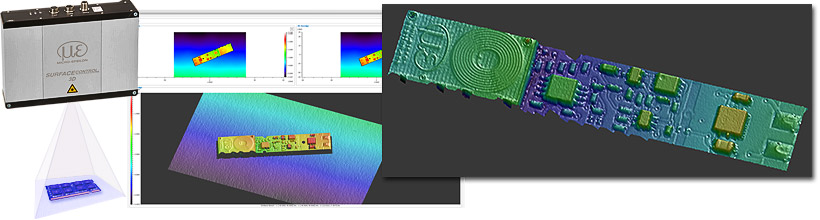

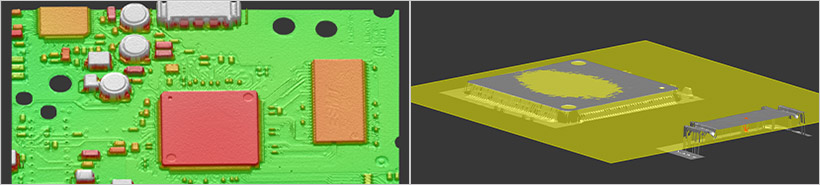

The high-performance surfaceCONTROL 3D 3200 snapshot sensor is ideally suited for use in industrial applications. It performs automated inline 3D measurements for geometry, shape and surface inspection on diffuse reflecting surfaces. The sensor is characterized by its compact design and high measurement accuracy combined with high data processing speed. With a high Z-axis repeatability of up to 0.6 µm, the sensor is ideal for precise 3D measurement and inspection tasks. Two different measuring ranges cover different measuring fields.

|

| |

New: surfaceCONTROL 3D 3200

|

| |

|

|

| |

|

* Evaluations from 3DInspect can be transmitted to a PLC via these fieldbuses. Sensor settings can be loaded by a controller via 3DInspect using parameter set mapping.

|

New generation of 3D measurements

|

|

| |

|

In addition to the fast data output, the surfaceCONTROL 3D 3200 also has an IO interface. EtherNet/IP, PROFINET and EtherCAT are available by using the 2D/3D Gateway II. 3D GigE Vision compatibility also allows easy integration into third-party image processing software. The comprehensive SDK for customer software integration rounds off the software package.

Application examples:

3D geometry inspection and form detection 3D geometry inspection and form detection Inspection of electronic components Inspection of electronic components Automation, production and process monitoring and quality control Automation, production and process monitoring and quality control Non-contact measurement of diffuse reflecting surfaces in the Stop&Go process Non-contact measurement of diffuse reflecting surfaces in the Stop&Go process Form, position and surface inspections Form, position and surface inspections

|

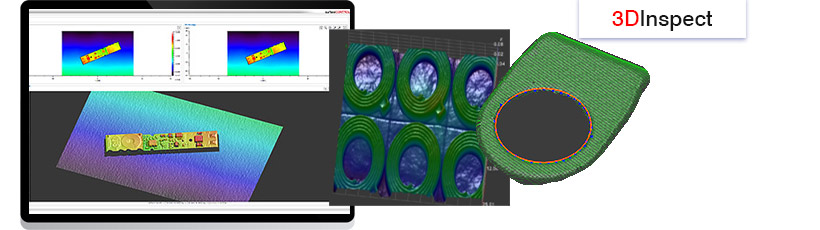

3DInspect software for 3D measurement tasks and inspection

|

|

| |

| The 3DInspect software is a powerful tool for sensor parameter set up and industrial measurement tasks. This software transmits the measurement data from the sensor via Ethernet and provides the data in three-dimensional form. This 3D data is further processed, evaluated and assessed with 3DInspect measuring programs on the PC and, if necessary, logged and transmitted via Ethernet to a control unit. If required, this 3D data can be saved with the software. Furthermore, the set up and configuration of the sensor is possible via the software. For connection to an automation interface, the functions of the 3DInspect Automation software add-on enables use of the SC3210 sensors, which also includes comprehensive data logging. |

| |

| |

|

|

|

|

|

|

|

|

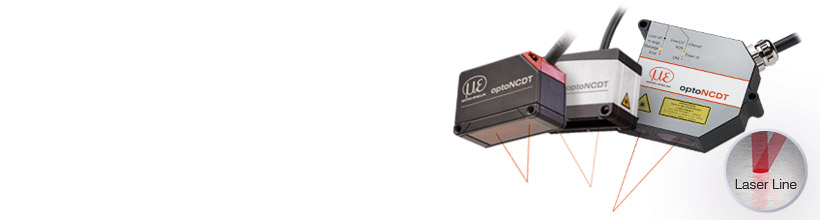

New: High precision Blue Laser displacement sensor – optoNCDT 2300-2DR

|

|

The optoNCDT 2300-2DR high precision laser triangulation sensor is designed for measurements on reflective and shiny targets. Due to its blue laser light, the measurement signal is extremely stable, i.e. the sensor measures down to the nanometer range. An extremely small laser spot size enables reliable detection of very small objects.

The sensor is, for example, used for thickness measurement of flat glass, assembly monitoring of extremely small parts and for distance measurements on annealed glass.

Operation is via a web browser that is addressed via an Ethernet interface. This interface enables making settings for the processing of measured values and signals, e.g., peak selection, filtering and masking features for video signals.

|

|

|

optoNCDT 2300-2DR

|

|

|

|

|

|

|

|

|

|

|

|

|

|

IC2001/USB Single-channel converter cable RS422/USB

|

|

|

|

The IC2001/USB single-channel converter cable is used for the USB connection of optical sensors equipped with an RS422 interface. The cable is easy to install and can therefore be used in machines and facilities.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

New: Smart laser sensor for shiny metallic objects – optoNCDT 1420LL

|

|

|

|

The compact optoNCDT 1420 LL laser sensors are designed for measurements of shiny metallic and rough surfaces. The oval light spot, which resembles a short laser line, can better compensate for unevenness such as texture and roughness. Special software algorithms filter out interference caused by surface roughness, defects, depressions or the smallest holes. |

|

|

|

|

|

|

|