|

|

|

3D sensors for geometry and surface inspections

|

|

|

|

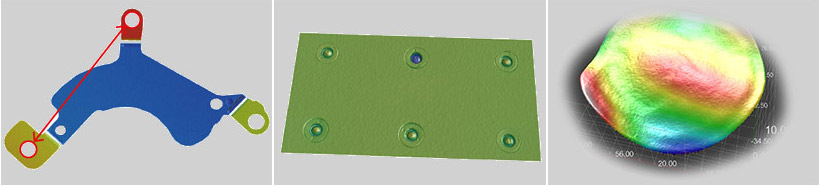

The new generation of Micro-Epsilon’s 3D sensors impresses with high accuracy during measurement and assessment of components and surfaces. The surfaceCONTROL and reflectCONTROL inspection systems from Micro-Epsilon are intended for matt and shiny surfaces respectively. The 3D snapshots are recorded in a short time and provide detailed 3D point clouds.

These 3D sensors are used, e.g., for geometric component testing, position determination, presence checks and the measurement of flatness or planarity. Thanks to their high performance, the sensors are used for inline applications, on robots and also for offline inspection.

|

|

|

|

|

|

|

Inline inspection with high precision

3D systems from Micro-Epsilon are used for a variety of measuring and inspection systems on matt and shiny surfaces. The results can be documented and are comparable. This allows for important conclusions to be drawn for process improvements. All 3D sensors from Micro-Epsilon can be used in offline applications as well as in fully automated operation and on the robot.

|

|

|

|

3D sensors for geometry and surface inspections

|

|

|

|

|

|

|

|

|

|

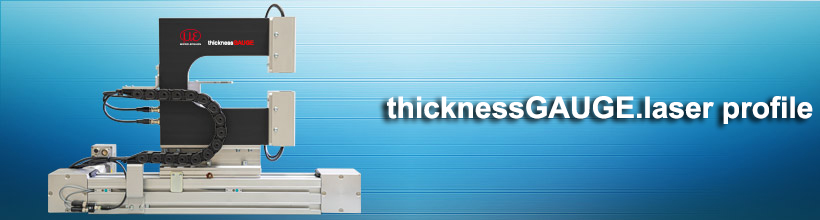

thicknessGAUGE.laser profile

|

|

|

|

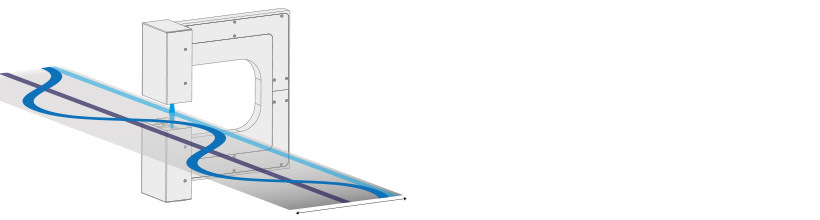

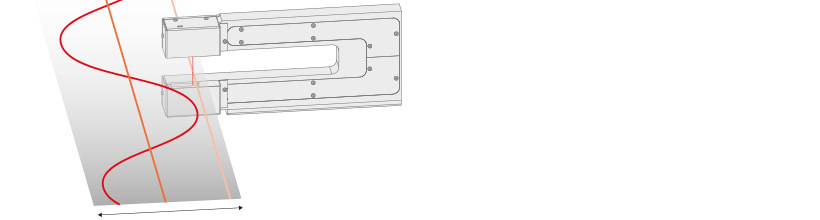

thicknessGAUGE.laser profile sensor systems use laser profile scanners for the thickness measurement. These scanners project a laser line onto the surface to be measured. The laser line compensates for strip tilting and enables profile averaging. The laser line measuring technique makes it possible to measure the thickness of structured materials such as embossed surfaces and perforated plates. |

|

|

|

|

|

|

|

|

|

|

|

|

The thicknessGAUGE.laser profile sensor system is used for precise thickness measurements of strips and plates. It can also be used for fixed track measurements, e.g., for center-line measurements (center thickness) or for thickness measurements on the edges. A linear unit enables traversing thickness measurements up to 400 mm strip width. |

|

|

|

|

|

|

|

thicknessGAUGE.confocal

|

|

|

|

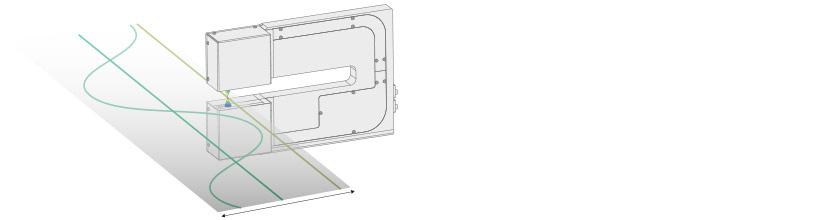

The thicknessGAUGE.confocal sensor systems use confocal chromatic displacement sensors for the thickness measurement. The sensors allow for measurements to be performed with outstanding accuracy and high measuring rates. In addition, this innovative measuring technique enables measurements of reflective and shiny surfaces as well as (semi-)transparent measuring objects. |

|

|

|

|

|

|

|

|

|

|

|

|

The thicknessGAUGE.confocal sensor system is used for precise thickness measurements of strips and plates. It can also be used for fixed track measurements, e.g., for center-line measurements (center thickness) or for thickness measurements on the edges. A linear unit enables traversing thickness measurements up to 400 mm strip width. |

|

|

|

|

|

|

|

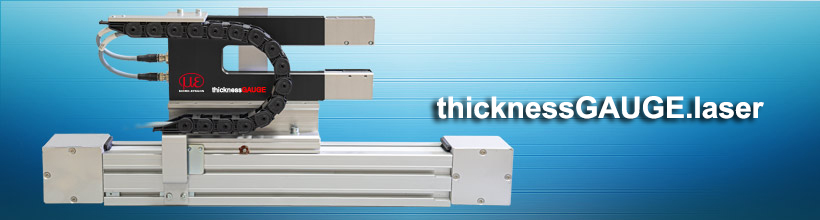

thicknessGAUGE.laser

|

|

|

|

thicknessGAUGE.laser sensor systems use laser triangulation sensors for the thickness measurement. These laser sensors enable high measuring rates at high speeds. The thicknessGAUGE.laser series impresses with a favorable price/performance ratio and is preferably used for thickness measurements of common surfaces such as plastics, wood and metals. |

|

|

|

|

|

|

|

|

|

|

|

|

The thicknessGAUGE.laser sensor system is used for precise thickness measurements of strips and plates. It can also be used for fixed track measurements, e.g., for center-line measurements (center thickness) or for thickness measurements on the edges. A linear unit enables traversing thickness measurements up to 400 mm strip width. |

|

|

|

|

|

|

|

|

|

|

|

Sensor system for precise thickness measurements

|

|

|

|

thicknessGAUGE sensor systems are used for precise thickness measurements of strip materials, plates and sheets up to 25 mm. Several models with different sensor types, measuring ranges and measuring widths enable inline thickness measurements of different materials and surfaces based on an unmatched price/performance ratio.

This fully assembled system comprises a stable frame on which two optical distance sensors are fixed, which detect the thickness of the measuring object according to the difference principle. The sensors are perfectly aligned to each other during the assembly. Furthermore, thickness calibration at the factory enables high precision thickness measurements.

A linear axis moves the sensor system from the parking position to the measuring position. A measurement standard for fully automatic calibration is in the parking position.

|

|

|

|

|

|

|

|

|

|

|

Thickness measurement with high precision

thicknessGAUGE sensor systems are used in industrial environments for precise thickness measurements of strip and plate materials. A linear unit with electromechanical drive enables thickness measurements in traversing mode. Alternatively, fixed track measurements are possible for center-line measurements (center thickness) or for thickness measurements on the edges.

|

|

|

|

Powerful analysis and control software

-

Multi-touch user interface Multi-touch user interface

-

Article database Article database

-

Production archive Production archive

-

Statistical evaluations Statistical evaluations

-

Limit value monitoring with return back to prodcution (optional fieldbus interfaces) Limit value monitoring with return back to prodcution (optional fieldbus interfaces)

-

Verification of gauge/test equipment capability Verification of gauge/test equipment capability

|

Automatic calibration & temperature compensation

thicknessGAUGE systems are equipped with in-situ calibration in order to compensate, e.g., for the effects of fluctuating temperatures. The calibration cycles are individually adjustable. In addition to temperature compensation, in-situ calibration enables proper functioning of the system to be verified cyclically and at any time.

|

|

|

100 % quality control during production

The thicknessGAUGE sensor systems are used in strip processes and plate production in order to measure the thickness continuously. Based on high precision and equipped with intelligent sensor technology, these sensor systems are used in various industries.

|

|

|

|

|

|

|

Thickness measurement of film, plastic plates, woven materials, wood and ceramics |

|

Thickness measurement of fuel cells and battery film (coated and uncoated) |

|

Thickness measurement of metal film, metal strips and metal plates |

|

|

|

Sensor system for precise thickness measurements

|

|

|

|

|

|

|

|

|

|