|

| |

|

|

| |

Capacitive rotation speed sensor for industrial measurement tasks

|

|

|

| |

|

|

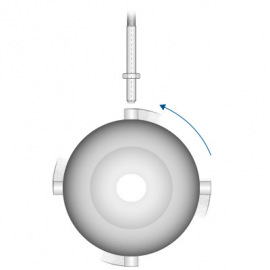

| The capaNCDT CST6110 is a capacitive rotation speed sensor system for counting tasks and rotational speed measurements of any type. The industrial measuring system consists of a dust proof, water tight controller and a compact sensors which can be integrated in confined spaces. The rotation speed sensor is used in centrifugal test benches, balancing machines, generators and engines, as well as shafts and drives. The CST6110 detects and counts blades, gearwheels and nubs with the highest precision and stability even in dusty, oily environments. |

| |

|

|

| |

Material-independent rotational speed measurement for universal use

Regardless of the material, the compact rotation speed sensor offers a high degree of interference immunity and reliability. Electrical conductors (metals) and insulators (plastic, ceramics, ...) are counted from the first detection with high signal quality. The rotation speed measurement is already performed from the first rotation up to a maximum of 400,000 rpm. The adjustable rotary switch supports the rotation output of objects which have several measuring points per rotation, e.g., rotor blades.

|

|

|

|

| |

Ideal for industrial counting tasks

|

|

|

|

|

| Axial installation: rotation speed monitoring on shafts |

|

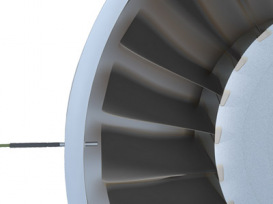

Radial installation: measurement in turbines |

|

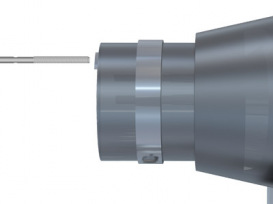

Axial installation: rotation speed in drilling rigs |

|

| |

| |

|

|

|

|

|

|

|

|

Rotation speed sensors

|

|

Rotation speed sensors are used to monitor, regulate and control mechanical drive systems and play a major role when it comes to protecting elements of a rotational system (e.g., in the engine, drive) from mechanical overload. Micro-Epsilon offers two sensor systems for rotation speed measurement. The capaNCDT CST6110 is a universal rotation speed sensor for counting tasks and rotation speed applications of any type. Moreover, the turboSPEED DZ140 measuring system is specifically designed for the detection of turbocharger rotation speeds. |

|

|

|

|

|

|

How do non-contact rotation speed sensors work?

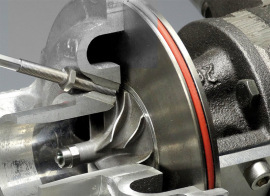

Non-contact rotation speed sensors from Micro-Epsilon use two different measuring techniques for rotation speed measurement. The CST6110 rotation speed sensor is based on the capacitive measuring principle while the inductive measuring principle is used for turbocharger rotation speed measurement using the DZ140. Both measuring techniques impress with their high signal stability and interference immunity. Unlike optical measuring procedures, rotation speed sensors from Micro-Epsilon are insensitive to dust and dirt.

|

|

|

Universal rotation speed measurement

The capaNCDT CST6110 capacitive rotation speed sensor is designed for industrial counting tasks and rotational speed applications. Regardless of the material, the sensor detects blades, gear wheels, nubs and similar objects with the highest precision. The measuring range is 1 to 400,000 rpm. Rotation output is performed from the first detection which means no system run up is required. The robust IP67 controller and a compact sensor design make the rotation speed sensor ideal for confined installation environments.

|

|

|

|

Turbocharger speed sensors

The inductive turboSPEED DZ140 sensor system is specially designed for engine compartment and turbocharger speed measurements. The controller is integrated in an IP65-protected miniature housing intended for operating temperatures up to 115 °C. The sensor resists temperatures up to 285 °C. Therefore, the robust miniature measuring system can be easily installed in the engine compartment. The inductive DZ140 measuring principle offers excellent interference resistance for increased EMC requirements, as well as in test cells and on-road testing, while providing precise measurement results in the range of 200 rpm to 400,000 rpm.

|

|

|

|

|

|

Rotational speed sensors for industrial measurement tasks

|

|

|

|

|

|

|

|

|

| |

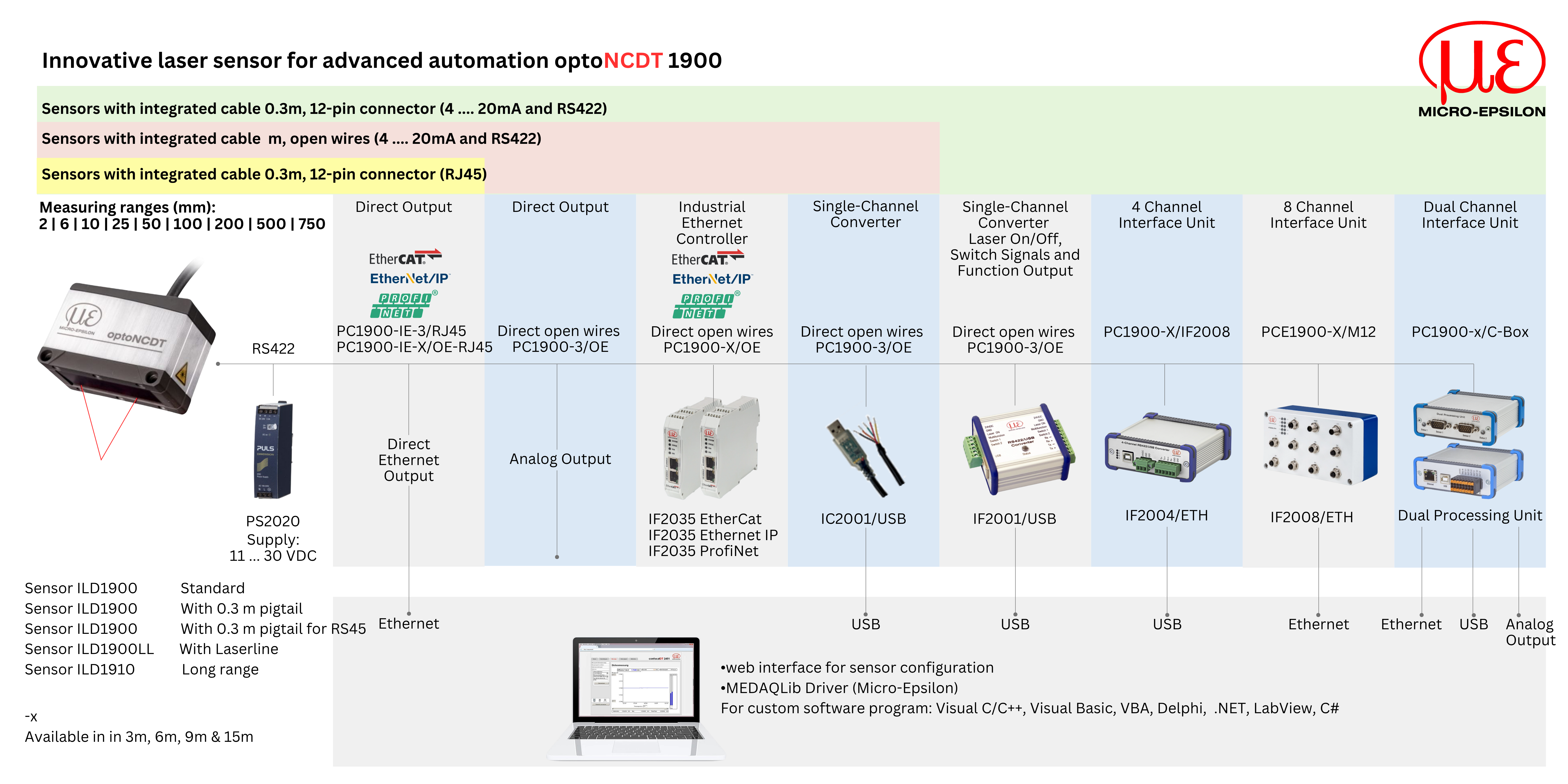

Laser displacement sensors for Advanced Automation  Product Technology Product Technology

|

| |

|

|

| |

|

| |

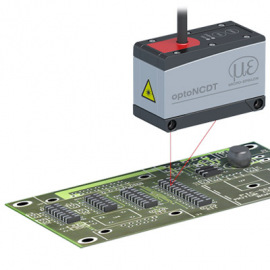

| The optoNCDT 1900 offers a unique combination of speed, size, performance and application versatility for displacement, distance and position measurements. This compact triangulation sensor achieves a high measurement accuracy and measuring rates of up to 10 kHz. The high-performance optical system generates a small light spot which enables to even detect the finest of details and structures reliably. |

| |

|

|

| |

|

|

Next-generation laser sensors

The optoNCDT 1900 is the latest model of Micro-Epsilon laser sensors. This innovative sensor is used for dynamic displacement, distance and position measurements and impresses with high speed, design and accuracy. The integrated high-performance controller enables fast and highly precise processing and output of measurement values. The innovative optoNCDT 1900 laser triangulation sensor is used whenever maximum precision is combined with the latest technology, e.g., in Advanced Automation, the automotive industry, 3D printing and coordinate measuring machines.

|

|

| |

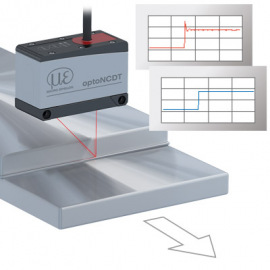

Highest stability based on intelligent signal optimization

For the first time, a two-step measurement value averaging is available to optimize the signal. This enables a smooth signal at edges and steps. Especially for high speed measurements of moving parts, the high-performance averaging enables a precise signal course.

|

|

|

|

| |

|

|

Advanced Surface Compensation - The intelligent exposure control for demanding surfaces

The optoNCDT 1900 is equipped with an intelligent surface control feature. New algorithms enable stable measurement results even on demanding surfaces presenting changing reflections. In addition, the sensor is extremely resistant to ambient light and can also be used in strongly illuminated environments. New algorithms compensate for ambient light up to 50,000 lux.

|

|

| |

Simple installation and initial operation

Mounting the sensor using fitting sleeves automatically aligns the sensor in the correct position. This enables both easy sensor replacement and even higher precision in solving measurement tasks. Thanks to its small dimensions, the laser sensor can also be integrated in confined spaces.

|

|

|

|

| |

Modern interfaces for integration into machines and systems

The laser sensor is equipped with an RS422 interface and analog outputs. The Micro-Epsilon interface modules also offer EtherNet/IP and PROFINET.

|

| |

| |

|