|

|

|

RS422/USB Converter IF2001/USB

|

|

The RS422/USB converter transforms digital signals from a laser-optical sensor into a USB data packet. The sensor and the converter are connected via the RS422 interface of the converter. Data output is done via USB interface. The converter loops through further signals and features such as laser on/off, switch signals and function output. The connected sensors and the converter can be programmed through software. |

|

|

|

|

|

|

|

|

|

|

|

Interface module IF1032/ETH

|

|

The IF1032/ETH interface module now enables to run sensors with analog interfaces with the proven web interface. With the Ethernet interface, measured data can be easily displayed on a PC. Moreover, sensors can be connected to an EtherCAT bus. The RS485 interface allows connection of new sensors using the Micro-Epsilon specific RS485 protocol. |

|

|

|

|

|

|

|

|

|

|

|

C-Box/2A controller for conversion and evaluation of up to 2 sensor signals

|

|

C-Box/2A is used for fast D/A conversion of two digital input signals or for evaluating two digital sensor signals. Output of the sensor signals is possible via two configurable analog outputs, Ethernet or USB. Handling of the C-Box/2A and of the connected sensors are performed via web interface. Averaging functions, thickness, diameter, step and inclinations can be calculated. The D/A conversion is executed with 16 Bit and max. 70 kHz. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Paint thickness measurement

|

Measuring paint thickness on CFRP and other substrates

|

|

|

|

The FSC is a non-destructive measurement device for fast thickness measurement of paint and other electrically insulating layers on substrates such as carbon fiber-reinforced plastics (CFRP), CFRP with metallic lightning protection and metals. This mobile device consists of a sensor and a controller for operating and display purposes. The system operates in a non-destructive manner using microwaves in the ISM band without requiring any coupling medium. The FSC is, among other things, used in the aviation industry and is certified for use by renowned aircraft manufacturers. |

|

|

|

|

|

|

|

|

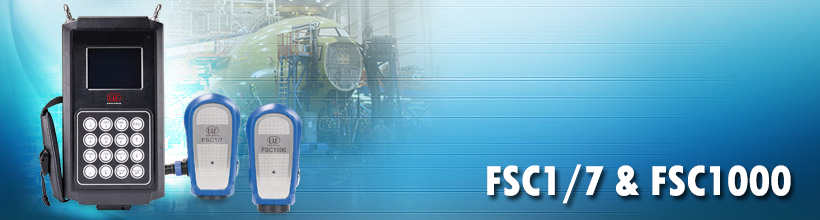

New: Paint thickness measurement of layers up to 500 μm – FSC1/7

|

|

|

|

The FSC1/7 is used to determine paint thickness on CFRP and other substrates and has a measuring range of 500 µm. In contrast to other measuring procedures, no minimum thickness is required which enables to detect even low layer thicknesses reliably. The measurement only lasts for approx. 1 second. The scope of supply includes reference films with known thickness based on which the measurement object can be calibrated. The calibration data can be stored and loaded at any time. The measurement can be exported via a USB connection for external further processing. |

|

|

New: Paint thickness measurement of layers up to 1000 μm – FSC1000

|

|

|

|

The FSC1000 is used to determine paint thickness of CFRP and other substrates. It offers a measuring range of 1000 µm. In contrast to other measuring procedures, no minimum thickness is required. The measurement only lasts for approx. only 1 second. The plastic films included with known thickness allow for the substrate material used to be calibrated. The calibration data can be stored and loaded later. The measurement data can be exported via USB for further processing. |

|

|

|

|

|

|

|

|

|

|

|

|

|

Some measurement tasks require large measuring ranges or a large measurement distance from the target object to be measured. For these types of applications, Micro-Epsilon offers long-range laser sensors that combine high accuracy with a large measurement distance. |

|

|

|

|

|

|

Precise laser sensor for measuring ranges up to 750 mm – optoNCDT 1750

|

|

The optoNCDT 1750 laser sensor offers measuring ranges of 500 mm and 750 mm and provides maximum accuracy and dynamics thanks to innovative evaluation algorithms. The sensor offers real-time surface compensation, which determines and controls the reflectance of the target during the exposure in real time. This enables reliable measurements on changing surfaces. Its universal setting and evaluation options allow the sensor to meet all requirements for use in highly dynamic industrial applications.reliable measurements on changing surfaces.

|

|

|

|

|

|

Industry standard laser sensor – optoNCDT 1760-1000

|

|

The optoNCDT 1760-1000 long-range laser sensor with a measuring range of 1000 mm is designed for applications where a high measurement distance is required. The sensor offers real-time surface compensation, which determines and controls the reflectance of the target during the exposure in real time. This enables reliable measurements on changing surfaces.

|

|

|

|

|

|

Large stand off laser sensors – optoNCDT 1710/2310

|

|

The optoNCDT 1710 and 2310 long-range laser sensors are designed for applications where a high measuring distance is required. However, the relatively small measuring range facilitates extremely precise measurement at a large distance.

|

|

|

|

|

|

|

|

|