|

|

|

|

|

|

|

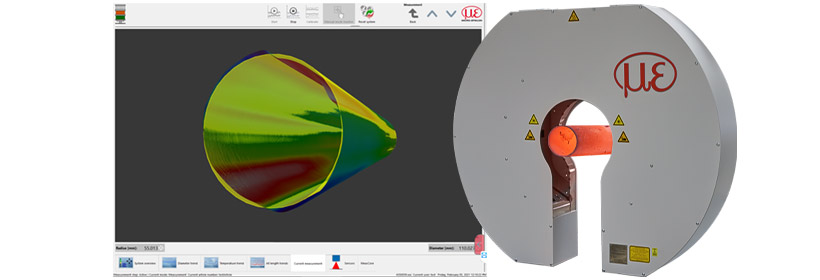

3D profile measurement of long products

|

|

Long products such as profiles, billets, etc., which are produced by rolling, drawing or forging, often have complex cross-sectional geometries. DimensionCONTROL measuring systems are used for geometrical inspection of long products. Depending on the application, these can be equipped with ThruBeam sensors, red and blue laser profile scanners to provide the optimal solution for the application. The systems operate with impressive precision even under the toughest hot rolling conditions. Integrated, fully automatic calibration compensates for the temperature-related, potential long-term drift of the mechanical structure.

The dimensionCONTROL MPG 8208 and MPG 9208 systems are designed as horseshoe frames and generate real 3D data with which the target values are calculated.

|

|

|

|

|

|

|

Profile measurement of red-hot glowing tubes with dimensionCONTROL MPG 9208

|

|

|

|

|

|

-

Measuring range up to 500 mm Measuring range up to 500 mm

-

Compact design for easy integration into the line Compact design for easy integration into the line

-

Can be equipped with ThruBeam sensors, red or blue laser line profile sensors Can be equipped with ThruBeam sensors, red or blue laser line profile sensors

-

Pneumatic protection of sensor optics, optional water cooling Pneumatic protection of sensor optics, optional water cooling

-

Flexible interface for communication with production Flexible interface for communication with production

|

|

|

|

|

|

|

|

|

|

|

|

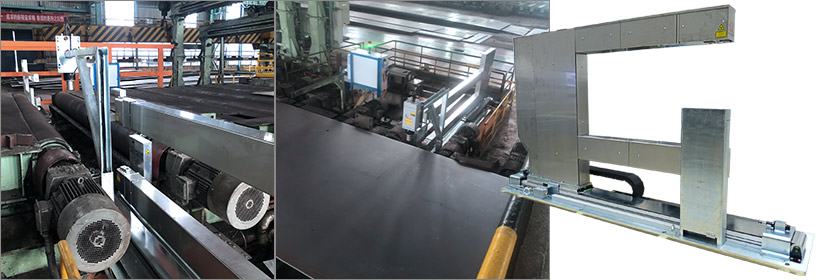

Heavy plates

|

|

With their large thicknesses, the products produced in heavy plate mills, which are used for example in bridges, pipelines or oil rigs, represent a challenge for isotope and X-ray equipment in terms of measurement technology and costs.

The thicknessCONTROL systems are equipped with special sensor technology and can precisely measure sheets and slabs with a thickness of more than 400 mm in both hot and cold states. Potential applications for the equipment are behind quarto stands for mill control or quality control, since the thickness is no longer changed downstream. Usually, reversing stands are used at this point, where a single C-frame measuring system detects the center thickness. If the plate is stopped for the change of direction, the width and thickness profile can also be measured.

The thicknessCONTROL 8202 and 9202 systems are also used in shearing lines for final quality assurance.

|

|

|

|

|

|

|

Measurement of thickness, width & length in shear lines with C-frame system thicknessCONTROL MTS 9202.LLT

|

|

|

|

|

|

|

For large widths (> 1000 mm), the C-frames of the thicknessCONTROL MTS 9202/ 8202 series are made of steel to ensure the required precision. This makes them ideal for use in wide heavy plate applications.

-

Available with blue or red laser line for red-hot glowing or non-glowing material Available with blue or red laser line for red-hot glowing or non-glowing material

-

Precise detection of the edge due to the high lateral resolution of the laser line enables width measurement Precise detection of the edge due to the high lateral resolution of the laser line enables width measurement

-

Easy integration of non-contact length measurement Easy integration of non-contact length measurement

-

Operation of multiple measuring systems from one human-machine interface Operation of multiple measuring systems from one human-machine interface

|

|

|

|

|

|

|

|

|

|

|

|

Cold mills / Processing lines

|

|

Thickness measurement for control and quality inspection is at many positions and so is an important element in the process landscape of cold rolling mills. Common places of application for systems for detecting the center thickness or the cross-profile are strip entry or exit of pickling lines with tandem mills, reversing mills as well as finishing lines.

Based on confocal sensor technology or laser line triangulation, Micro-Epsilon offers high-precision thickness measuring systems with the thicknessCONTROL MTS 8201/8202 series, which operate with high precision in the submicrometer range.

In processing lines, such as for tinning, hot-dip galvanizing or painting, thickness measuring systems are used at many points to ensure that the high demands on the product as well as on efficiency are met. Due to the wide portfolio of sensor technologies with which the thicknessCONTROL systems are available, high precision can be achieved for a wide variety of surfaces. For further measurement tasks in the area of process lines, Micro-Epsilon offers infrared temperature sensors and displacement sensors.

|

|

|

|

|

|

|

Thickness measurement in the leveling line with the thicknessCONTROL MTS 8202.LLT C-frame system

|

|

|

|

|

|

|

For thin sheets, Micro-Epsilon offers a high precision technology with the confocal thicknessCONTROL MTS 8201/8202.

-

High data rate of up to 6.5 kHz enables high-performance signal processing High data rate of up to 6.5 kHz enables high-performance signal processing

-

Ideal for reflective surfaces Ideal for reflective surfaces

-

High tolerance for tilting thanks to a measuring angle of up to 48° High tolerance for tilting thanks to a measuring angle of up to 48°

-

Integrated calibration within seconds to compensate for thermal effects Integrated calibration within seconds to compensate for thermal effects

-

High data density for profile thickness measurement thanks to high traversing speed High data density for profile thickness measurement thanks to high traversing speed

-

Material widths of up to 1000 mm with C-frame and 3000 mm with O-frame Material widths of up to 1000 mm with C-frame and 3000 mm with O-frame

|

|

|

Thickness measurement in the pickling line with thicknessCONTROL MTS 8201.LLT O-frame systems

|

|

|

|

|

|

|

The variants of the thicknessCONTROL MTS 8201/8202 series, in which laser line technology is used, demonstrate their advantages especially in the harshest environmental conditions:

-

Reliable measurement despite steam and emulsion, additional air purge can be integrated Reliable measurement despite steam and emulsion, additional air purge can be integrated

-

Precise with a wide range of surface conditions Precise with a wide range of surface conditions

-

Large measuring range of 60 mm with high precision +/-2 µ Large measuring range of 60 mm with high precision +/-2 µ

-

Integrated calibration within seconds to compensate for thermal effects Integrated calibration within seconds to compensate for thermal effects

-

Material widths up to 2500 mm with C-frame and 3000 mm with O-frame Material widths up to 2500 mm with C-frame and 3000 mm with O-frame

|

|

|

|

|

|

|

|

|

|

|

|

Steel and non-ferrous metals

|

|

Iron and steel represent a fundamental pillar in industrial production. Precision in the production process of metal plates, sheets and coils is crucial to the efficient use of scarce resources and economic success.

As a manufacturer of measuring systems for the steel industry based on optical sensors, Micro-Epsilon offers a comprehensive portfolio without radioactivity that ensures More Precision in all applications regardless of complexity and material properties. With optimized sensor technology tailored to the respective application, innovative mechanical design, as well as cooling and protective devices, the systems meet the challenges of the processes.

The high-performance signal processing and analysis software makes the systems the leading optical measuring systems on the market which detect the following parameters:

-

Thickness Thickness

-

Thickness profile, wedge and crown Thickness profile, wedge and crown

-

Temperature and temperature cross profile Temperature and temperature cross profile

-

Width Width

-

Cambering Cambering

Service is the basis for a long-term partnership. We provide 24/7 maintenance and service with qualified staff. Support is initially provided via hotline and remote maintenance. This means that the majority of faults can be identified quickly and rectified cost-effectively.

In addition, our employees are quickly on site from our service hubs to establish reliable operation of the systems.

|

|

|

|

|

|

Steel and non-ferrous metals

|

|

|

|

Hot mills

Cold mills

Heavy plates

Long products

Service centers and cutting lines

|

|

|

|

|

|