|

|

|

|

|

What is colorSENSOR measuring principle?

|

|

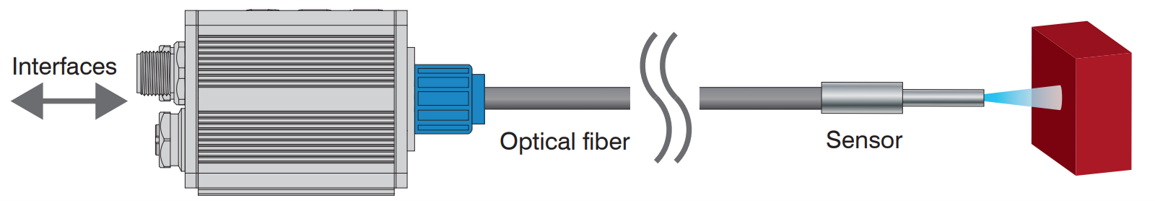

In the field of color inspection, a measurement channel usually consists of a sensor (also referred to as probe head or sensor head) and a controller (evaluation unit). The surface to be measured is illuminated via the sensor cable (fiber optics). The light (color) reflected by the surface is detected by the sensor and evaluated by the controller. The sensors have different measuring geometries and can optionally be extended by mountable lenses for focusing or to achieve larger measurement distances. Models with integrated controller of the OT series are also available for large measurement distances.

|

|

|

|

|

The specimen is illuminated with homogeneous, white light from an LED. A CFS sensor is used to project a point of illumination onto the surface to be inspected. The light is reflected diffusely at a specified angle and transmitted by the same sensor to a perceptive True Color receiver (XYZ) where it is analyzed.

The three wavelength ranges, i.e.

X = long wave, X = long wave,

Y = medium wave and Y = medium wave and

Z = short wave light portions Z = short wave light portions

from the specimen are used to determine the diffuse color reflections and thereby transformed into a selected color space. These color values are calculated according to the procedure described in DIN 5033. The transformed values (colors), are stored in the controller and continuously compared to the current color. When the colors are all within the entered tolerance range, a recognition signal is sent to the digital switching outputs and the keypad indicators. This process allows storage of multiple colors in various color spaces. In the same manner, the color values and the recognized color are output as data protocol via the available interfaces as required.

|

|

|

Color Spaces

|

|

With the colorSENSOR CFO you can measure the following color spaces: XYZ, xyY, L*a*b*, L+u*v*, L*u‘v‘.

|

|

|

Color Tolerance Models

|

|

Relative color measurement is often referred to as color inspection. The color of the measuring object and the reference sample is detected with the same sensor and the color distance (Delta Erel) is evaluated based on the difference of the values.

Note: The color distance between target and reference sample is determined with the same sensor (Delta Erel).

|

|

|

|

The CFO controller works with a relative color measurement and thus with different tolerance models. The permissible color distance for the color to be controlled is stored in a tolerance model. If the measured value is outside the tolerance, the CFO controller outputs the switching output for Color not recognized. If the measured value is within the tolerance, the corresponding output for the detected color is signaled.

|

|

|

|

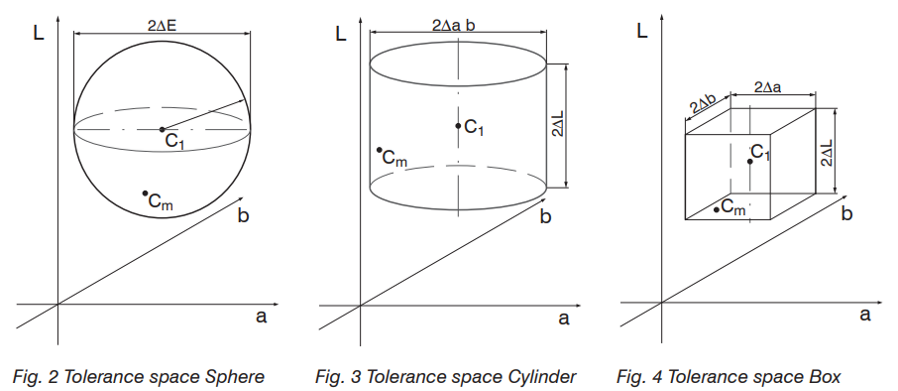

The system can be set to the distance models Sphere (∆E), Cylinder (∆L; ∆ab), Box (cuboid, ∆L; ∆a; ∆b) and Classify. These models form a tolerance space around the learned colors.

|

|

|

|

|

|

|

C1 = learned color 1

Cm = detected color

For an evaluation of color deviations, the color tolerance parameters should be based on the perception thresholds for color differences. In the Lab color space, a tolerance threshold of ∆E > 1 is frequently used for perceptible color differences.

Influencing factors for setting color tolerance parameters:

Required accuracy for color recognition Required accuracy for color recognition

Tolerance for reading variations. Tolerance for reading variations.

|

|

|

|

A change in the color readings for one and the same specimen can have two causes:

-

Internal factors. Change in readings due to detector noise, changes in brightness of the light source or modulated ambient light Internal factors. Change in readings due to detector noise, changes in brightness of the light source or modulated ambient light

-

External factors. Deviations in color or surface texture of specimens or in measuring conditions (distance, angle) External factors. Deviations in color or surface texture of specimens or in measuring conditions (distance, angle)

|

|

|

Define the color distance tolerances so that the tolerance limits are greater than the change in the readings for acceptable specimens

|

|

The Sphere tolerance space or rather ∆E denotes the color distance in a color space or how far apart the colors of the target and the reference object to be compared are in the spatial model. The larger the difference between the colors, the more clearly the difference can be perceived. For the tolerance model Sphere only one value can be set, (∆E = root(∆L^2+∆a^2+∆b^2)). With this tolerance model, it is not possible to determine in which color parameter the decisive change in color is present.

If you select the tolerance space Cylinder, tolerance values are set and evaluated separately for the brightness value L and the color values a/b.

Tolerance space Cylinder is useful if higher distance variants are present during the measurement, since here the value for brightness L and the values for color a and b are assigned to separate tolerance parameters.

|

|

|

|

In the Box tolerance model, separate tolerance values can be set for the L, a and b color values. This enables more precise color inspections.

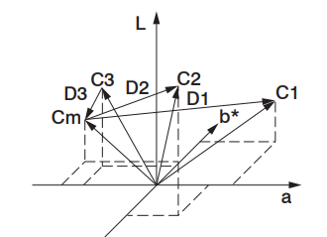

With Classify the current color readings are associated with the closest color value (shortest direct distance) saved in the color table. In this mode, classification is always accomplished regardless of the actual similarity between the selected colors.

For example, if red is the only color saved in the table, all color readings are associated with this color. In the diagram below, three colors are stored in the controller, C1...C3. Cm corresponds to the currently measured color. In the Classify mode, the controller now determines to which stored color the delta E (D1 ... D3) from Cm to C1 ... C3 is the smallest.

Since the distance D3 between Cm and C3 is the smallest, the detected color is assigned to the color output of color C3 and output by the controller.

|

|

|

|

|

|

|

|

|

|

|

Inspection of the interior Varnish coating in aluminum cans

|

|

Sorting of plastic components (connector colors)

|

|

Recognition of anti-reflection coating on lenses

|

|

Color detection of kitchen fronts

|

|

|

|

|

|

|

|

|

|

|

Capacitive rotation speed sensor for industrial measurement tasks

|

|

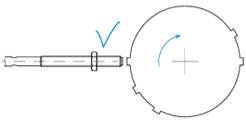

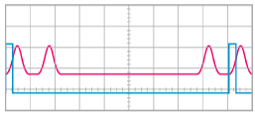

The capaNCDT CST6110 is a capacitive measuring system for non-contact rotation speed measurement of conductive measurement objects such as metals and non-conductive objects such as ceramics or plastics. This non-contact measurement is performed, for example, in drives, on rotor blades or on position marks of shafts. The sensor can be mounted in axial and radial direction to the target in order to detect objects such as blades, teeth, rings or nubs. The measuring range from 1 to 400,000 rpm enables the detection of both the startup from the first rotation and high rotational speeds reliably. The adjustable rotary switch supports the rotation output of objects which have several measuring points per rotation, e.g., rotor blades. Data output is via a voltage output or a digital interface.

|

|

|

How does RPM sensor works?

|

|

When positioned near a turning rotor, gear, shaft or other regularly moving device, RPM sensors detect the mechanical rotating parts and convert mechanical motion into electric pulses without direct contact. The resultant output signals are then fed to a digital counter, totalizer, tachometer, or other monitoring and control device.

|

|

|

|

|

|

Characteristics

|

-

Material-independent rotation speed measurement of 1 … 400,000 rpm Material-independent rotation speed measurement of 1 … 400,000 rpm

-

Precise counting from the first detection Precise counting from the first detection

-

Adjustable rotary switch (max. 16) for rotation output Adjustable rotary switch (max. 16) for rotation output

-

High interference immunity and reliability High interference immunity and reliability

-

Easy integration due to compact sensor size Easy integration due to compact sensor size

-

Robust controller with IP67 Robust controller with IP67

|

|

|

Ideal for industrial counting tasks

|

|

|

|

|

|

|

Axial installation: rotation speed monitoring on shafts |

|

Radial installation: measurement in turbines |

|

Axial installation: rotation speed in drilling rigs |

|

|

|

|

|

|

|

|

What is the measuring principle of magneto-inductive distance sensors?

|

|

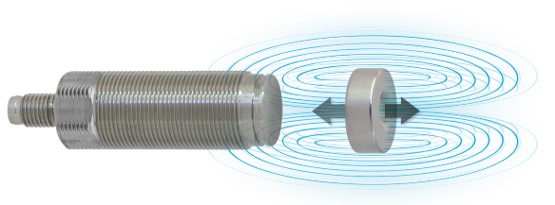

Magneto-inductive distance sensors (Patented Pending).

The mainSENSORis based on an innovative measuring principle developed by Micro-Epsilon in order to combine the advantages of both inductive and magnetic sensors.

|

|

|

|

|

|

|

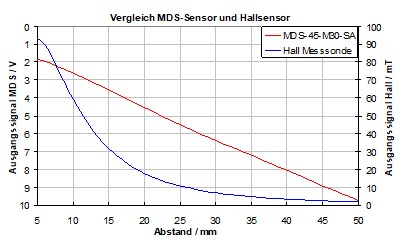

A magnet is fixed to the measurement object. The movement of the magnet induces a change in the magnetic flow in the sensor element, which is detected by the sensor coil. A linear relationship between output signal and magnet distance (self-linearization technology) is produced due to counteracting physical effects.

Different magnet with magnet strength are applied thus providing option of difference measuring ranges, up to 55 mm, these sensors are also used in special applications such as rotational speed measurement of, e.g., shafts and gear wheels.

|

|

|

Characteristics

|

-

Ideal alternative to inductive sensors and proximity sensors Ideal alternative to inductive sensors and proximity sensors

-

Linear output signal, high basic sensitivity and temperature stability Linear output signal, high basic sensitivity and temperature stability

-

Selectable measuring ranges up to 55mm with different magnets Selectable measuring ranges up to 55mm with different magnets

-

Long-life sensor due to non-contact measurement Long-life sensor due to non-contact measurement

-

Ideal for customer-specific designs and serial applications Ideal for customer-specific designs and serial applications

|

|

|

Advantages

|

|

Linear relation between signal and magnet distance (self-linearization) despite large, frontal measuring range

Compared to Hall Effectsensors

Linear output signal Linear output signal

Increased frontal measuring range Increased frontal measuring range

Compared to inductive sensors

Significantly larger measuring range Significantly larger measuring range

Stable sensitivity at end of measuring range Stable sensitivity at end of measuring range

Compact sensor design (e.g. M12 with MR of 55 mm) Compact sensor design (e.g. M12 with MR of 55 mm)

|

|

|

|

|

|

Flexible sensor concept

|

|

Due to their flexible concept, the sensors are ideal for a wide range of applications, particularly where big quantity and low priceare required. The standard sensors are designed in a stainless steel M12, M18 and M30 or a flat plastic housings suitable for industrial applications. Customer-specific modifications to the plate and sensor housing can be easily carried out for serial applications.

|

|

|

|

|

|

Defining the measuring range using magnets

|

|

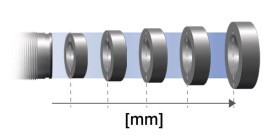

With the magneto-inductive measuring principle, the magnets used act as target. To achieve difference measuring range, it is only necessary to change the magnet. Further calibration or sensor settings are superfluous. Therefore, measuring ranges of 20 to 55mm can be achieved using only one sensor.

|

|

|

|

|

|

Measurement through objects

|

|

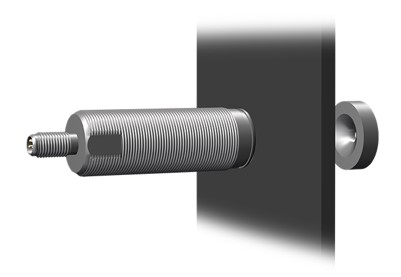

Unlike conventional measuring methods, the magneto-inductive sensors enable measurements through non-ferromagnetic materials, particularly metals such as aluminum or stainless steel. A clear benefit is provided here as the sensor and the magnet can be installed separately in applications with closed systems or housings. It is therefore possible to mount the sensor safely in harsh environments.

|

|

|

|

|

|

|

|

|