|

| |

|

|

|

|

| |

Industrial draw-wire sensors for long-life operation

|

| |

|

|

| |

|

|

| |

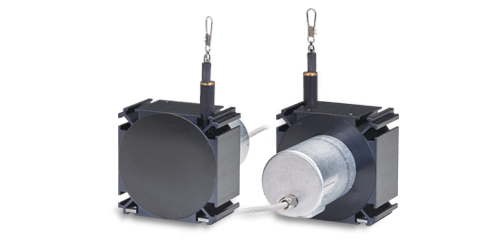

| Draw-wire sensors of the P series are designed for industrial measurement tasks. A compact and robust aluminum housing protects the sensor from mechanical damage. As well as analog versions with potentiometer, current or voltage output, digital versions with incremental or absolute encoders are available, providing measuring ranges up to 50m. |

| |

|

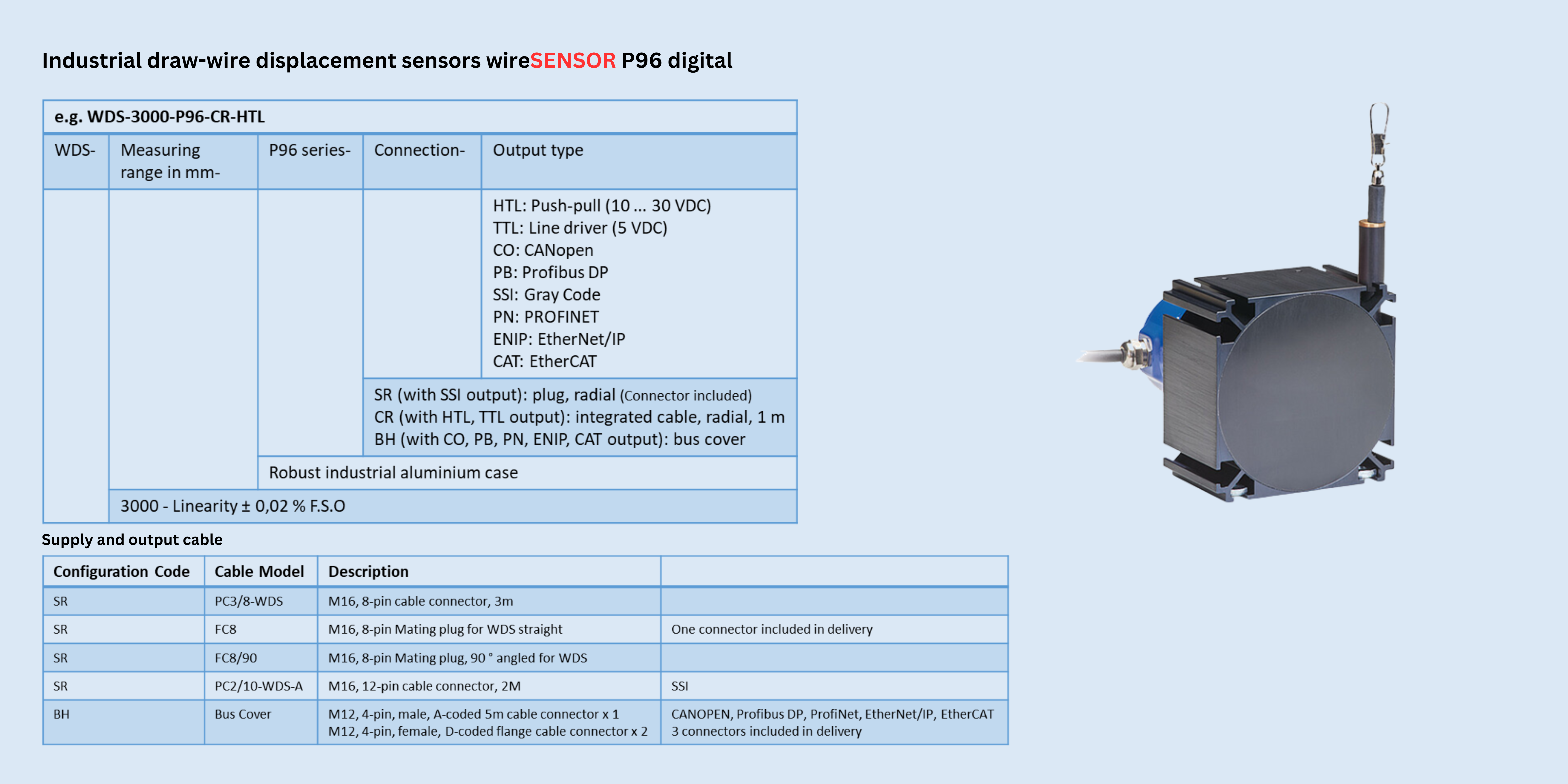

Industrial draw-wire sensors – wireSENSOR WDS-P96 digital

|

|

Draw wire sensors of the P96 Series are designed for general use. Numerous options enable a suitable sensor to be selected for almost any application. Various measuring ranges and digital output types facilitate fast integration for many application areas.

|

|

|

|

| |

| |

|

| |

|

|

|

|

| |

Industrial draw-wire sensors for long-life operation

|

| |

|

|

| |

|

|

| |

| Draw-wire sensors of the P series are designed for industrial measurement tasks. A compact and robust aluminum housing protects the sensor from mechanical damage. As well as analog versions with potentiometer, current or voltage output, digital versions with incremental or absolute encoders are available, providing measuring ranges up to 50m. |

| |

|

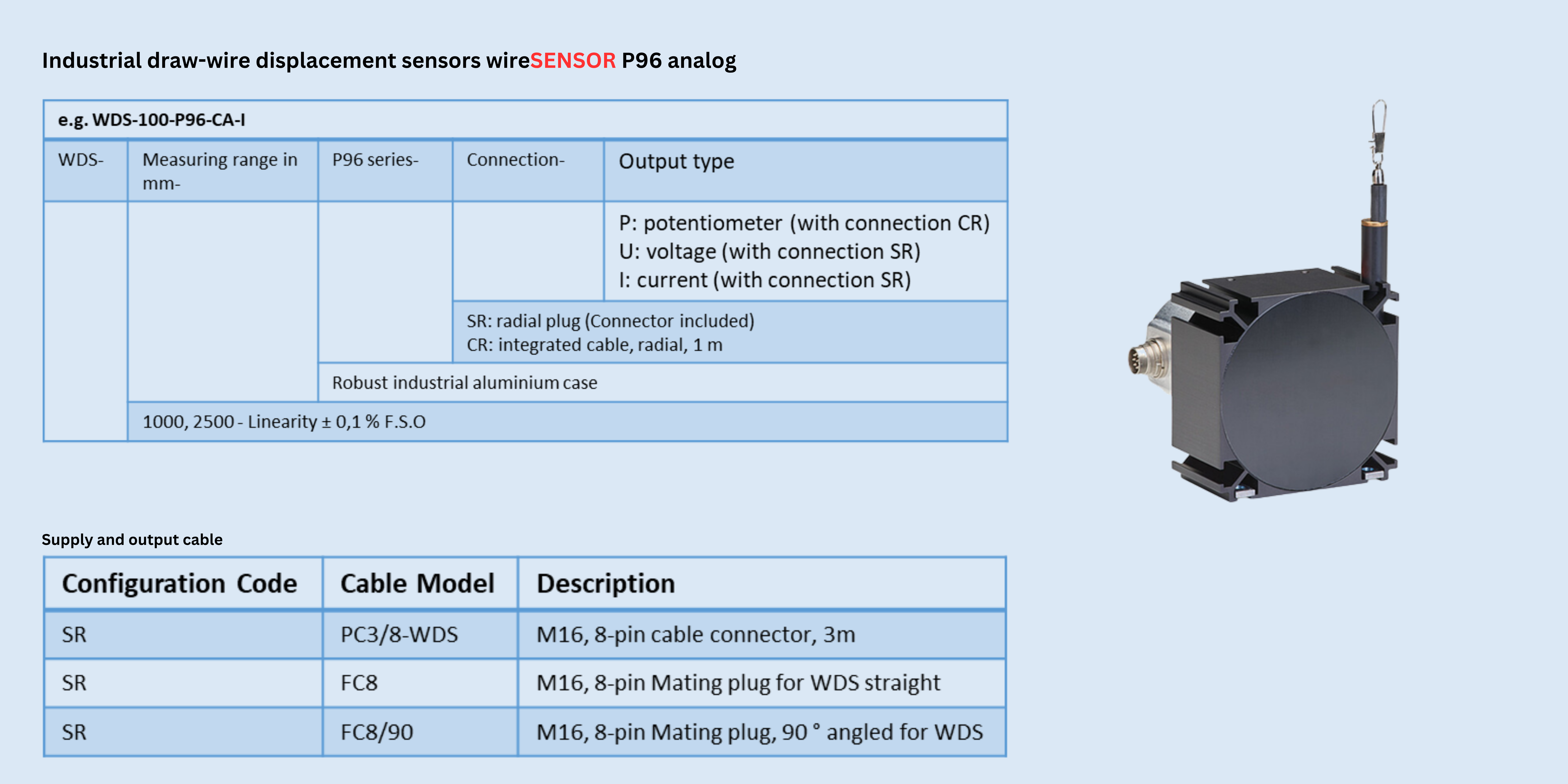

Industrial draw-wire sensors – wireSENSOR WDS-P96 analog

|

|

Draw wire sensors of the P96 Series are designed for general use. Numerous options enable a suitable sensor to be selected for almost any application. Various analog outputs and measuring ranges make many applications possible.

|

|

|

|

| |

| |

|

| |

|

|

|

|

| |

Industrial draw-wire sensors for long-life operation

|

| |

|

|

| |

|

|

| Draw-wire sensors of the P series are designed for industrial measurement tasks. A compact and robust aluminum housing protects the sensor from mechanical damage. As well as analog versions with potentiometer, current or voltage output, digital versions with incremental or absolute encoders are available, providing measuring ranges up to 50m. |

|

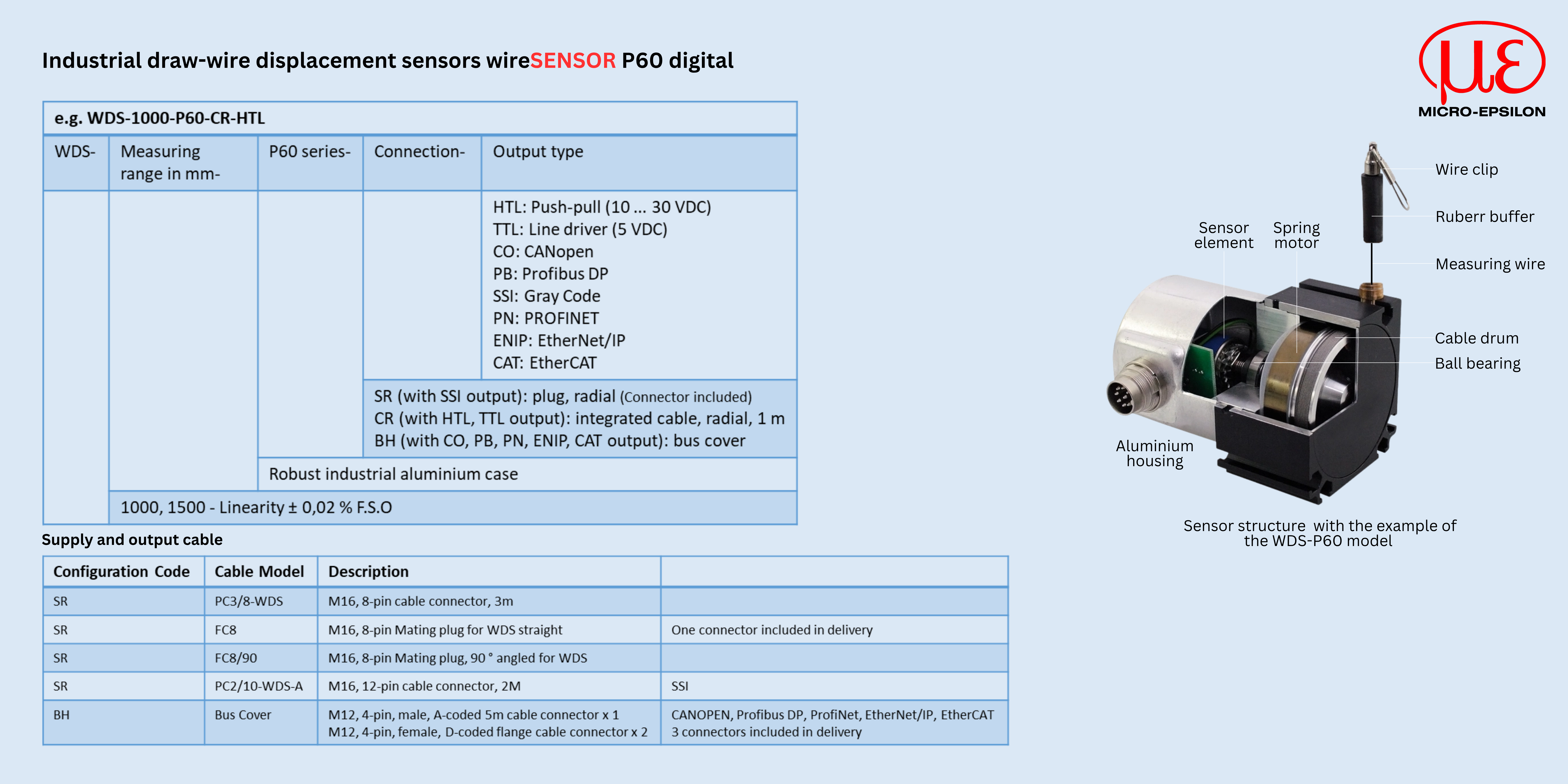

Industrial draw-wire sensors – wireSENSOR WDS-P60 digital

|

|

Draw wire sensors of the P60 Series are designed for general use. Numerous options enable a suitable sensor to be selected for almost any application. Various measuring ranges and digital output types facilitate fast integration for many application areas.

|

|

|

|

| |

| |

|

| |

|

|

|

|

| |

Industrial draw-wire sensors for long-life operation

|

| |

|

|

| |

|

| |

| Draw-wire sensors of the P series are designed for industrial measurement tasks. A compact and robust aluminum housing protects the sensor from mechanical damage. As well as analog versions with potentiometer, current or voltage output, digital versions with incremental or absolute encoders are available, providing measuring ranges up to 50m. |

| |

|

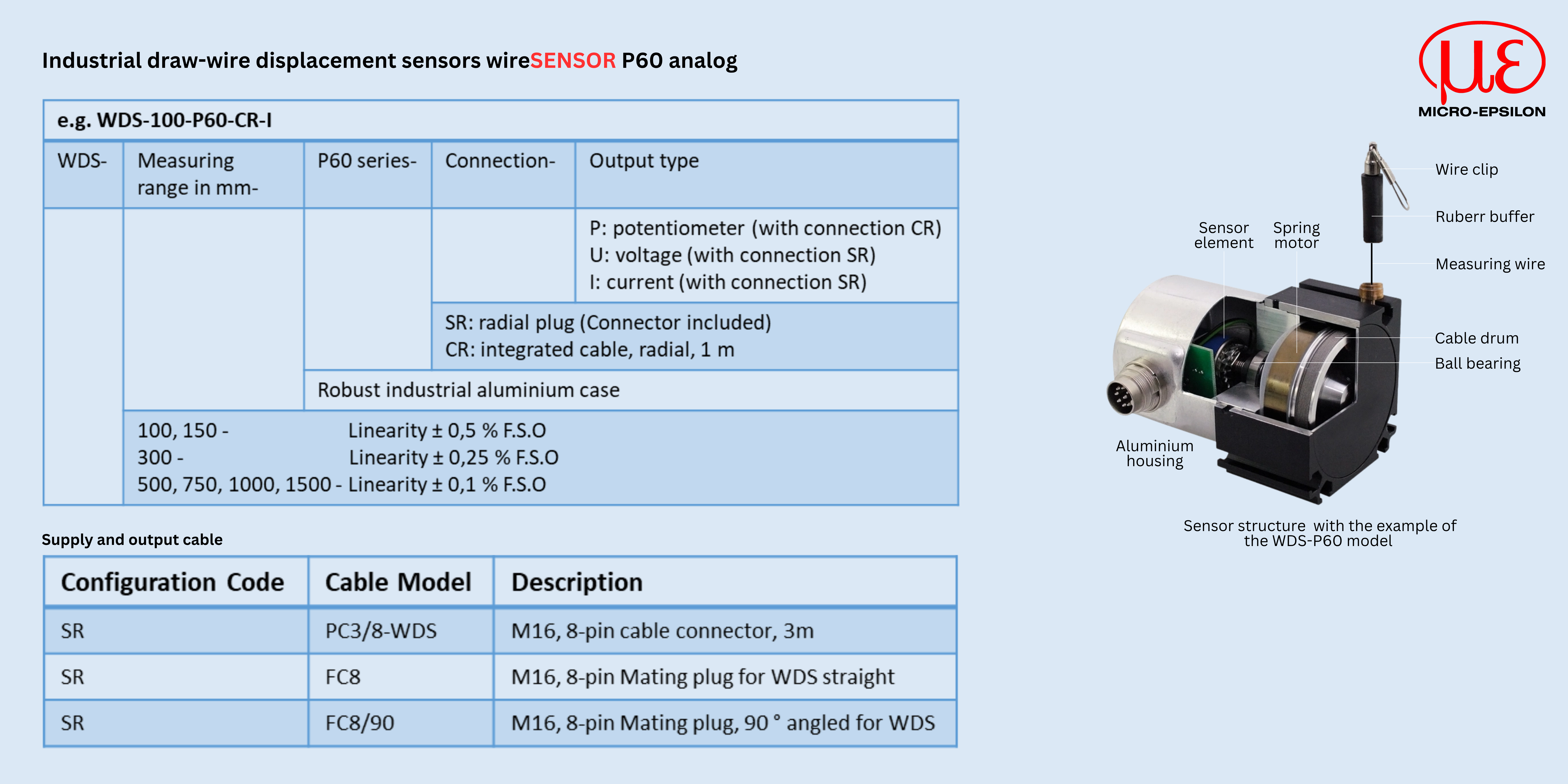

Industrial draw-wire sensors – wireSENSOR WDS-P60 analog

|

|

Draw wire sensors of the P60 Series are designed for general use. Numerous options enable a suitable sensor to be selected for almost any application. Various analog outputs and measuring ranges make many applications possible.

|

|

|

|

| |

| |

|

|

| |

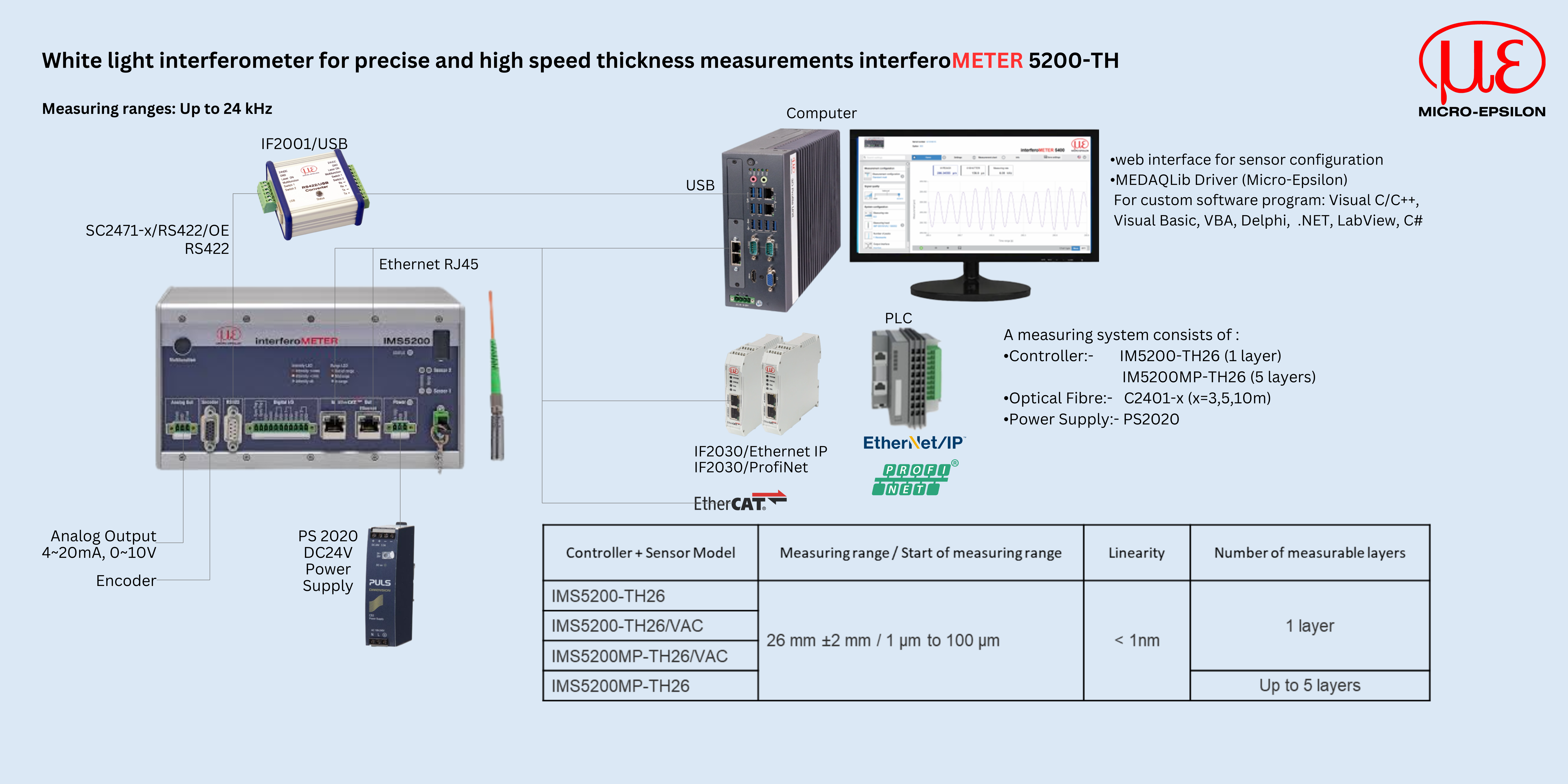

White light interferometer for reliable thickness measurement with submicron accuracy  Product Technology Product Technology

|

| |

|

|

| |

|

| |

|

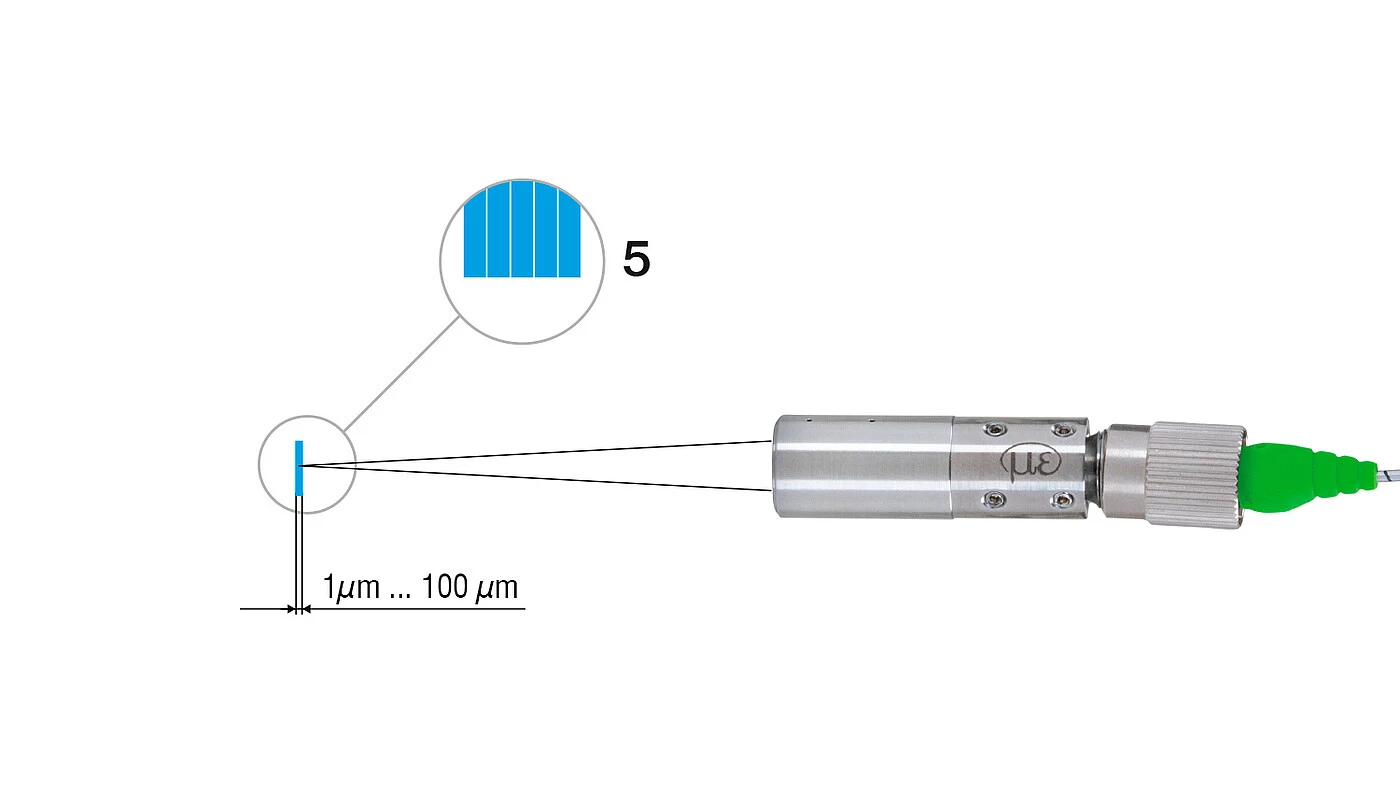

| The new IMS5200-TH white light interferometer opens up new possibilities for fast and reliable thickness measurements. The controller features intelligent evaluation and enables precise thickness measurement of transparent layers as thin as 1 µm. Their high measuring rate up to 24 kHz makes the IMS5200 models ideal for industrial use. Nanometer accuracy for layers as thin as 1 µm. |

|

| |

|

|

For air gap measurement between two glass plates (n~1), the measuring range is 1.5 µm ... 150 µm. For glass thickness measurement (with refractive index ~1.5), it is 1 µm to 100 µm.

|

|

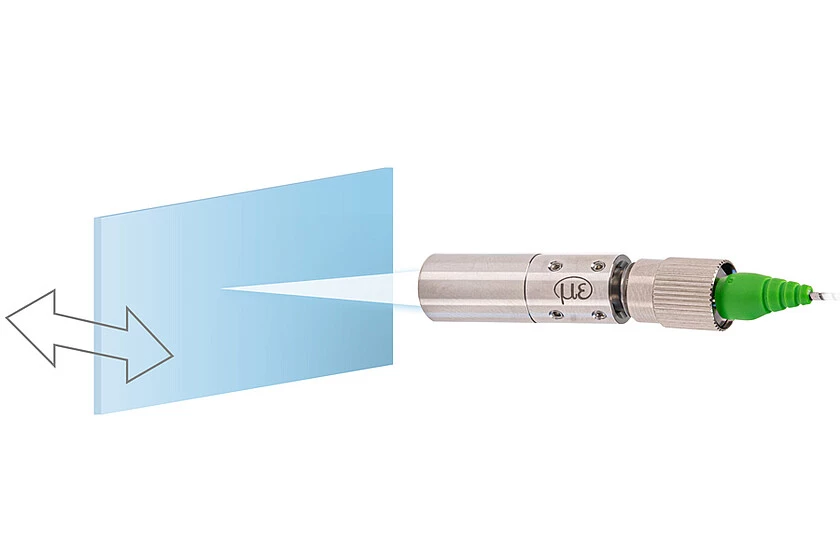

Reliable thickness measurement with varying measurement distances

The IMS5200-TH white light interferometer is used for high-precision thickness measurements. A decisive advantage here is the distance-independent measurement, where a nanometer-accurate thickness value is achieved even with moving objects. The measuring range of 1 to 100 µm enables the measurement of thin transparent layers and films.

|

|

With the multi-peak controller variant, several signal peaks can be evaluated simultaneously. This allows multi-layer thickness measurement of transparent objects and laminated glass. The controller outputs the thickness values with the highest stability regardless of their position.

|

|

|

|

|

|

The robust sensor and the controller in a metal housing make the system ideally suitable for integration into production lines. With its compact design and large operating range, the sensor is easy to integrate. It provides stable measurement results even in vibrating environments. The controller can be installed in the control cabinet on a DIN rail. Cable lengths up to 10 m allow a spatial separation of sensor and controller. Commissioning and parameterization are conveniently performed via web interface and do not require any software installation.

|

|

| |

| |

|