|

| |

|

|

|

|

|

|

| |

|

|

| |

|

|

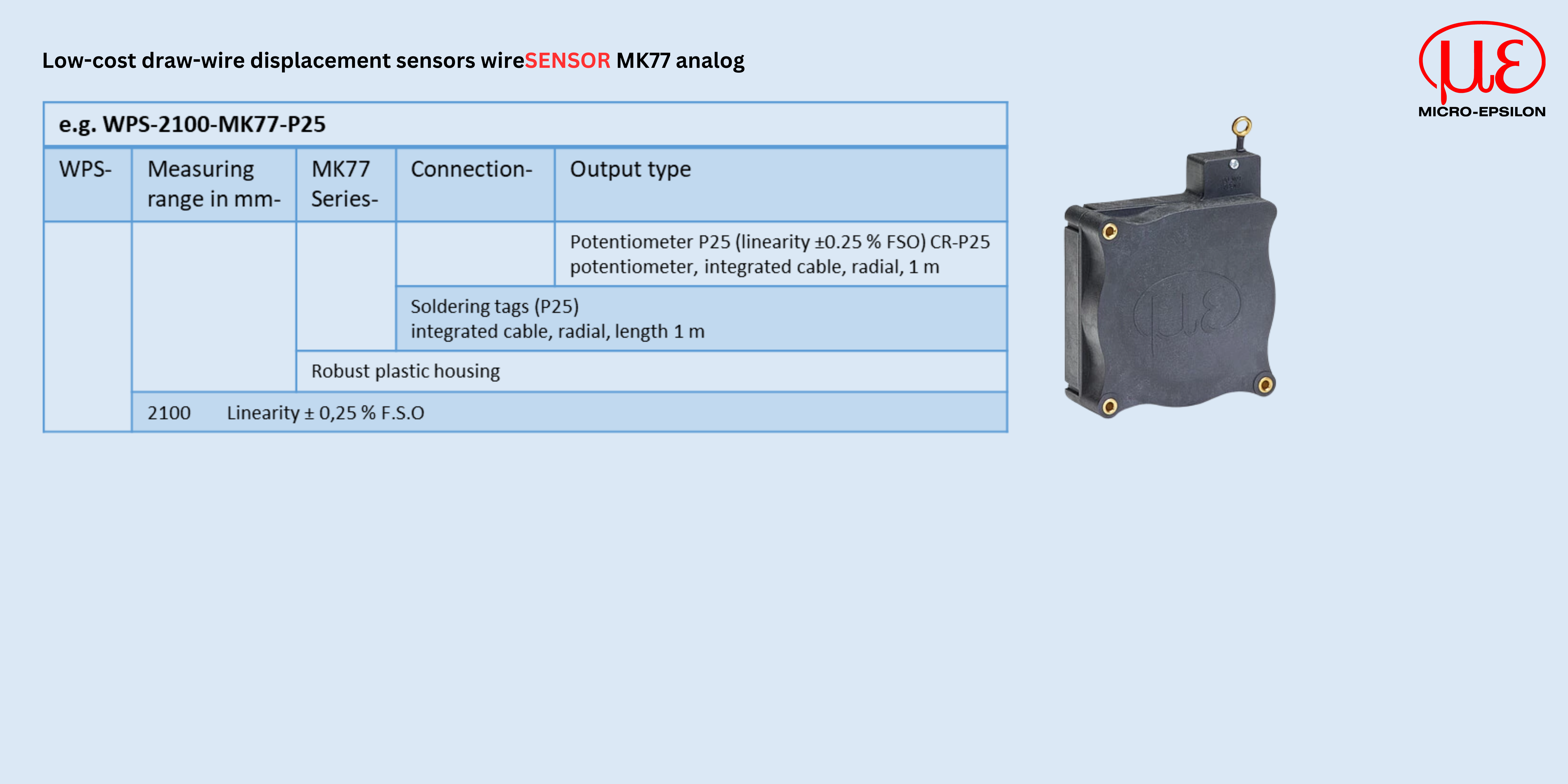

wireSENSOR WPS-MK77 analog

|

|

The miniature draw-wire sensors of the MK series are specially designed for use in high-volume production. Due to the favorable price and the compact size of the sensor, new potential designs and cost optimization are the benefits to the user.

|

|

|

|

| |

| |

|

| |

|

|

|

|

|

|

| |

|

|

| |

|

|

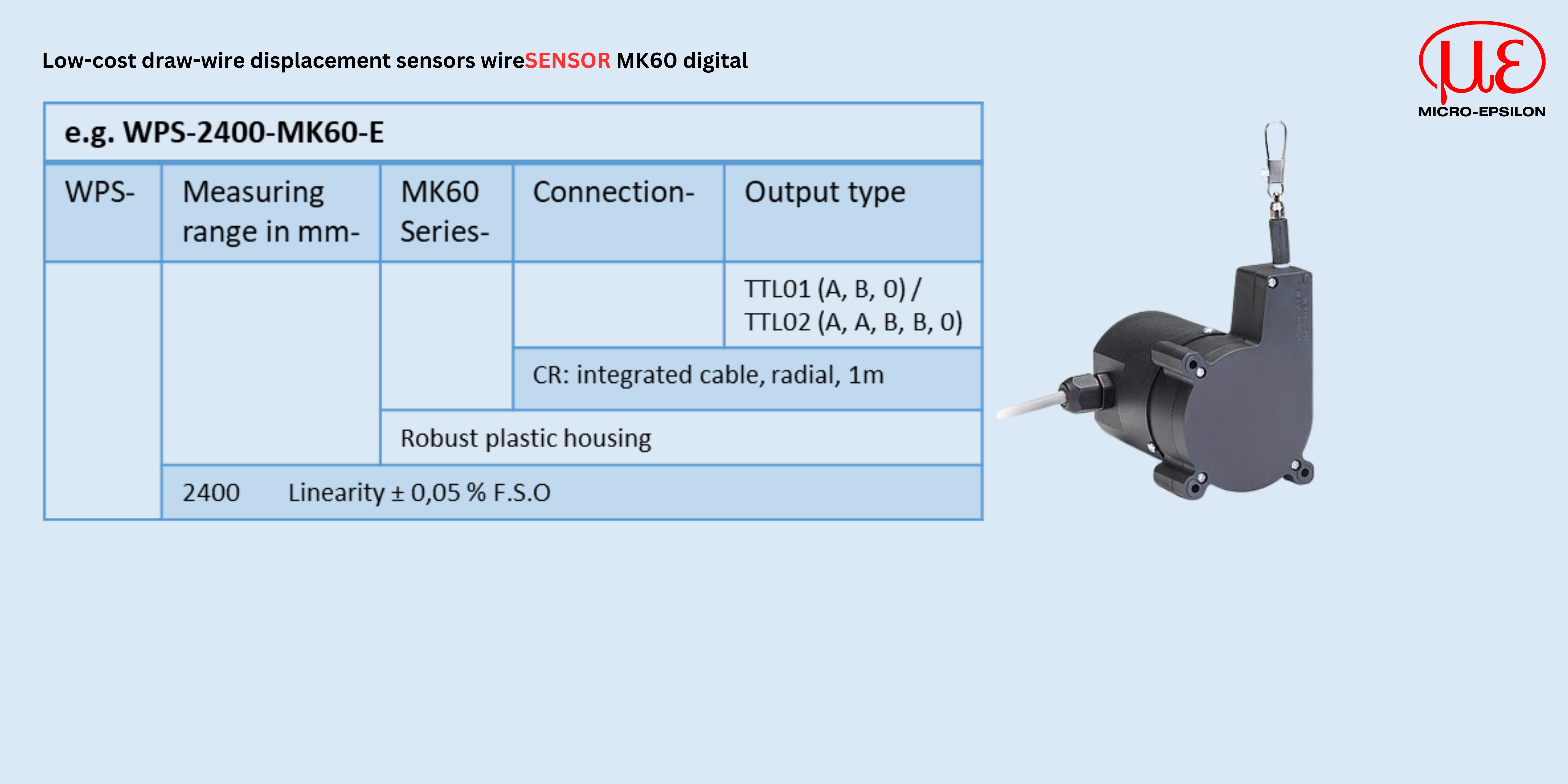

wireSENSOR WPS-MK60 digital

|

|

The miniature draw-wire sensors of the MK series are specially designed for use in high-volume production. Due to the favorable price and the compact size of the sensor, new potential designs and cost optimization are the benefits to the user.

|

|

|

|

| |

| |

|

| |

|

|

|

|

|

|

| |

|

|

| |

|

|

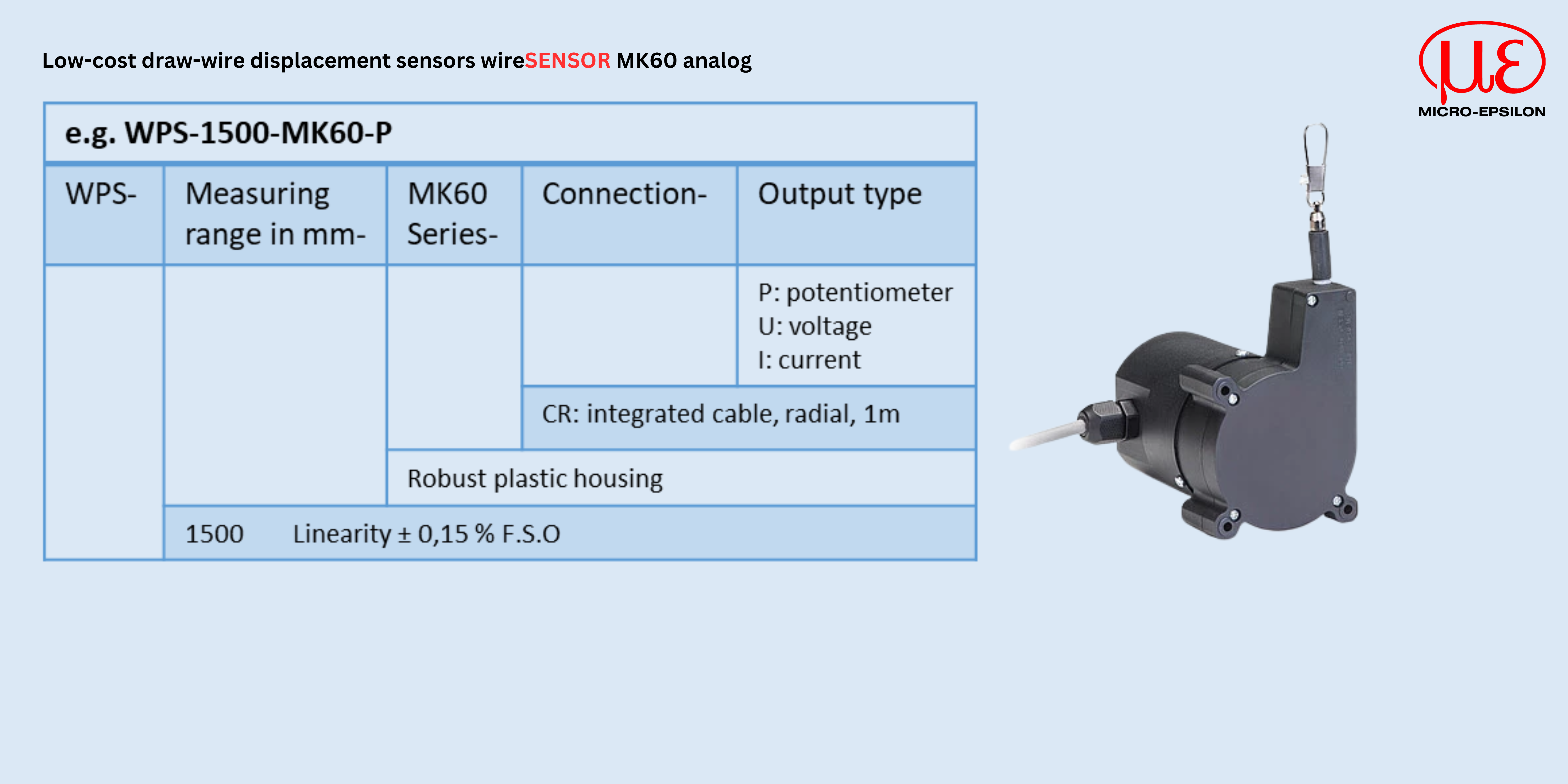

wireSENSOR WPS-MK60 analog

|

|

The miniature draw-wire sensors of the MK series are specially designed for use in high-volume production. Due to the favorable price and the compact size of the sensor, new potential designs and cost optimization are the benefits to the user.

|

|

|

|

| |

| |

|

| |

|

|

|

|

|

|

| |

|

|

| |

|

|

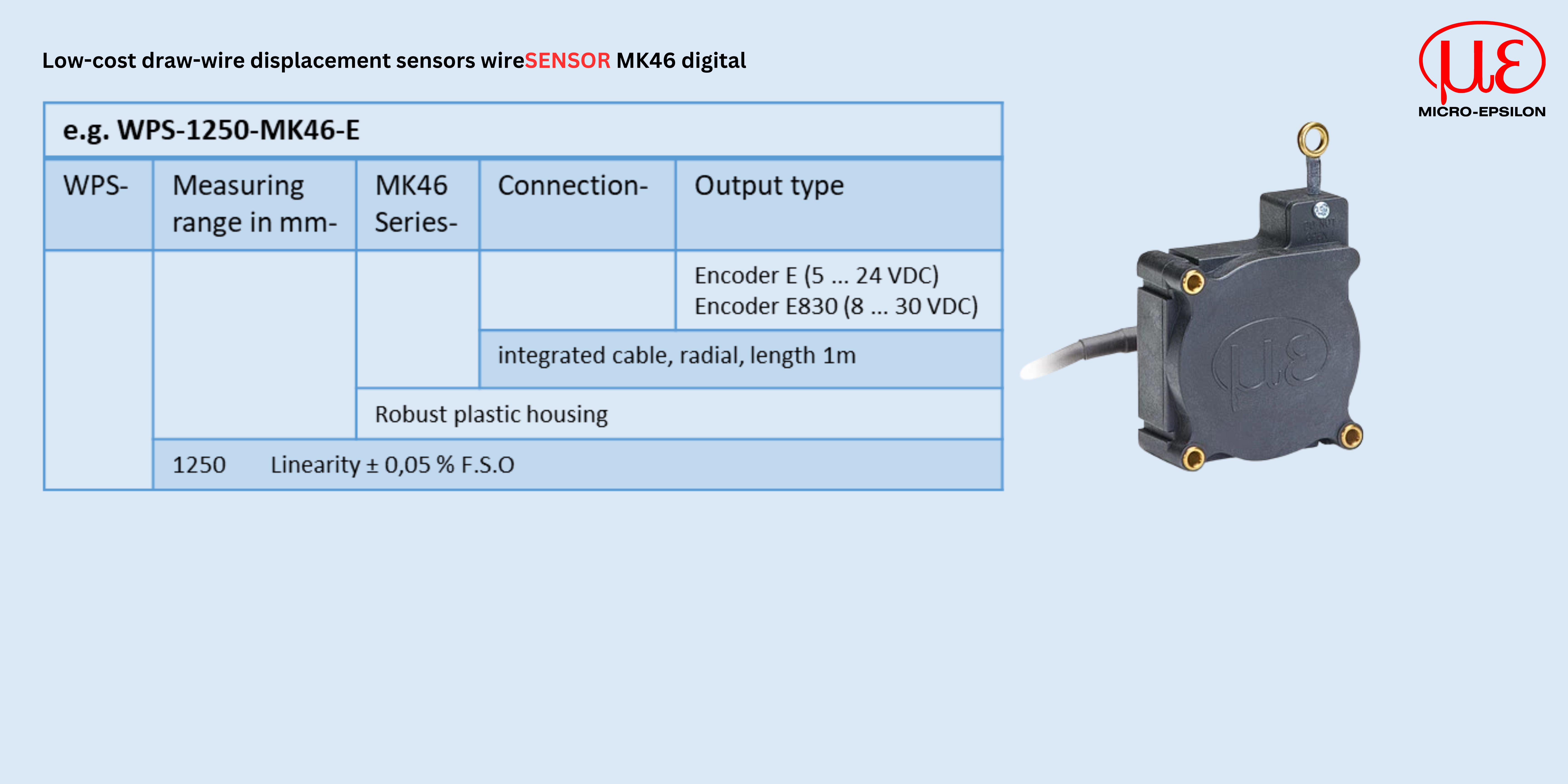

wireSENSOR WPS-MK46 digital

|

|

The miniature draw-wire sensors of the MK series are specially designed for use in high-volume production. Due to the favorable price and the compact size of the sensor, new potential designs and cost optimization are the benefits to the user.

|

|

|

|

| |

| |

|

| |

|

|

|

|

|

|

| |

|

|

| |

|

|

wireSENSOR WPS-MK46 analog

|

|

The miniature draw-wire sensors of the MK series are specially designed for use in high-volume production. Due to the favorable price and the compact size of the sensor, new potential designs and cost optimization are the benefits to the user.

|

|

|

|

| |

| |

|