|

|

|

|

|

|

|

Capacitive rotation speed sensor for industrial measurement tasks

|

|

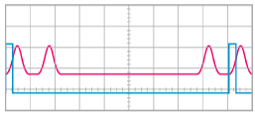

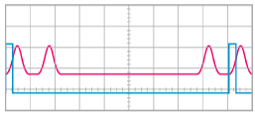

The capaNCDT CST6110 is a capacitive measuring system for non-contact rotation speed measurement of conductive measurement objects such as metals and non-conductive objects such as ceramics or plastics. This non-contact measurement is performed, for example, in drives, on rotor blades or on position marks of shafts. The sensor can be mounted in axial and radial direction to the target in order to detect objects such as blades, teeth, rings or nubs. The measuring range from 1 to 400,000 rpm enables the detection of both the startup from the first rotation and high rotational speeds reliably. The adjustable rotary switch supports the rotation output of objects which have several measuring points per rotation, e.g., rotor blades. Data output is via a voltage output or a digital interface.

|

|

|

How does RPM sensor works?

|

|

When positioned near a turning rotor, gear, shaft or other regularly moving device, RPM sensors detect the mechanical rotating parts and convert mechanical motion into electric pulses without direct contact. The resultant output signals are then fed to a digital counter, totalizer, tachometer, or other monitoring and control device.

|

|

|

|

|

|

Characteristics

|

-

Material-independent rotation speed measurement of 1 … 400,000 rpm Material-independent rotation speed measurement of 1 … 400,000 rpm

-

Precise counting from the first detection Precise counting from the first detection

-

Adjustable rotary switch (max. 16) for rotation output Adjustable rotary switch (max. 16) for rotation output

-

High interference immunity and reliability High interference immunity and reliability

-

Easy integration due to compact sensor size Easy integration due to compact sensor size

-

Robust controller with IP67 Robust controller with IP67

|

|

|

Ideal for industrial counting tasks

|

|

|

|

|

|

|

Axial installation: rotation speed monitoring on shafts |

|

Radial installation: measurement in turbines |

|

Axial installation: rotation speed in drilling rigs |

|

|

|

|

|

|

|