|

|

|

|

|

|

|

Replacement Gaiters |

Gaiters can be replaced when damaged. Only pneumatic push probes require gaiter rings.

Part Numbers:

|

Spring Push |

|

Part Number |

Pneumatic Push |

Part Number |

|

A6G/1/S |

D6P/2/S |

205014 |

|

|

|

|

AX/1/S |

DP/2/S |

204851 |

AX/1/P |

DP/2/P |

802691 |

|

AX/1.5/S |

|

204851 |

|

|

|

|

AX/2.5/S |

DP/5/S |

204894 |

AX/2.5/P |

DP/5/P |

802692 |

|

AX/5/S |

DP/10/S |

204860 |

AX/5/P |

DP/10/P |

802693 |

|

AX5/1/S |

DP10/2/S |

204860 |

AX5/1/S |

DP10/2/P |

802693 |

|

|

DP/12/S |

209562 |

|

DP/12/P |

|

|

AX/10/S |

DP/20/S |

205906 |

AX/10/P |

DP/20/P |

803235 |

|

|

|

|

|

|

|

|

|

LE/12/S |

209562 |

|

LE/12/P |

805098 |

|

|

LE/25/S |

205906 |

|

LE/25/P |

804241 |

|

|

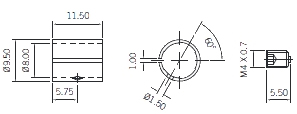

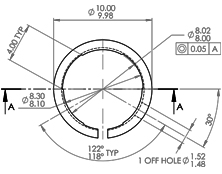

Clamping Collet |

Ø9.5 mm |

Ø10 mm |

|

805048 (M4 Screw)

806788 (M3 Screw)

|

806460-SX (M4 Screw) |

|

|

|

|

For use with all 8 mm clamping shaft sensors. The clamping collet distributes the clamping forces evenly around the shaft. Using the supplied grub screw, the probe can be loosened while holding the collet in place. |

|

Probe Tips |

Various probes are available. See Probe tips |

|

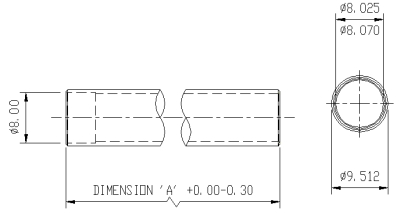

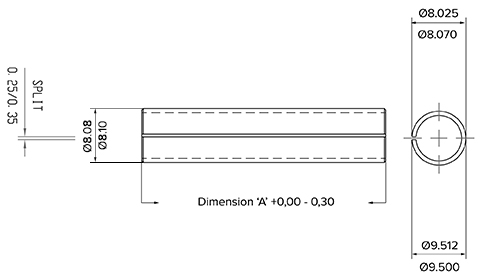

Imperial Adapter Sleeves |

Adapter Sleeves can be used to increase the body diameter of 8 mm sensors to 9.512 (3/8"). Available in lengths A from 12 to 127 mm.

|

|

Imperial Adapter Sleeves

(Split)

|

Split Adapter Sleeves can be used to increase the body diameter of 8 mm sensors to 9.512 (3/8"). Available in lengths A from 12 to 127 mm.

|

|

|

|

|

|

|

|

|

|

|

Pneumatic Push Automatic Digital Gauging Probe (DP/P) - Specification

|

Standard |

|

Axial Cable Outlet |

DP/2/P |

DP/5/P |

DP/10/P |

DP/20/P |

DP10/2/P |

|

Radial Cable Outlet |

DPR/2/P |

DPR/5/P |

DPR/10/P |

DPR/20/P |

DPR10/2/P |

|

|

|

Measurement Performance |

|

Measurement Range (mm) |

2 |

5 |

10 |

20 |

2 |

|

Accuracy (% of Reading) (Note 1) |

0.05 |

0.05 |

0.06 |

0.07 |

0.05 |

|

Accuracy (% of Reading) (Note 1) - with In Line Connector |

0.2 |

0.15 |

0.15 |

0.15 |

0.2 |

|

Repeatability (worst case) µm (Note 2) |

0.15 |

0.15 |

0.15 |

0.15 |

0.15 |

|

Repeatability (typical) µm (Note 3) |

0.05 |

0.05 |

0.07 |

0.07 |

0.05 |

|

Resolution (µm) |

0.01 |

0.05 |

0.05 |

0.1 |

0.01 |

|

Pre Travel (mm) |

0.15 |

0.15 |

0.15 |

0.15 |

0.15 |

|

Post Travel (mm) |

0.85 |

0.85 |

0.85 |

0.85 |

8.85 |

|

Tip Force (N) at Middle of Range ±20% |

|

|

|

|

|

|

Pneumatic at 0.4 Bar |

0.7 |

0.7 |

0.7 |

0.7 |

0.7 |

|

Pneumatic at 1 Bar |

2.6 |

2.6 |

2.6 |

2.6 |

2.6 |

|

Temperature Coefficient %FS/°C |

0.01 |

0.01 |

0.01 |

0.01 |

0.01 |

|

|

|

Environmental |

|

Sealing for Probe |

IP65 with gaiter or IP50 without gaiter |

|

Sealing for Probe Interface Electronics |

IP43 for module and TCON |

|

Storage Temperature (°C) |

-20 to +80 |

|

Probe Operating Temperature with Gaiter (°C) |

-5 to +80 |

|

Probe Operating Temperature without Gaiter (°C) |

-10 to +80 |

|

Electronics Operating Temperature (°C) |

0 to +60 |

|

EMC Emissions |

EN61000-6-3 |

|

EMC Immunity |

EN61000-6-2 |

|

Probe Life |

100 million cycles (no side load), > 10 million cycles in most applications |

|

|

|

Material |

|

Probe Body |

Stainless Steel |

|

Probe Tip (options) |

Nylon, Ruby, Silicon Nitride, Tungsten Carbide |

|

Gaiter (Note 6) |

Fluoroelastomer or Silicon |

|

Cable |

PUR |

|

Electronics Module |

ABS |

|

|

|

Electronics Interface (Orbit®3) |

|

Orbit®3 Interface Options |

USB, Ethernet, RS232 |

|

Reading Rate |

3906 readings per second |

|

Bandwidth of Electronics (Hz) user selectable |

460, 230, 115, 58, 29, 14, 7, 4 |

|

Power |

5±0.25 VDC @ 0.06A typical |

|

|

|

1Accuracy 1 µm or % reading, whichever greater. |

|

2Repeated operation against a carbide target with side load applied to the bearing using max-min. |

|

3Repeated operation against a carbide target standard deviation from average (68%) |

|

6Different gaiter materials available for specific applications - Fluoroelastomer standard option |

|

|

|

|

|

|

|

|

|

|

|

|

|

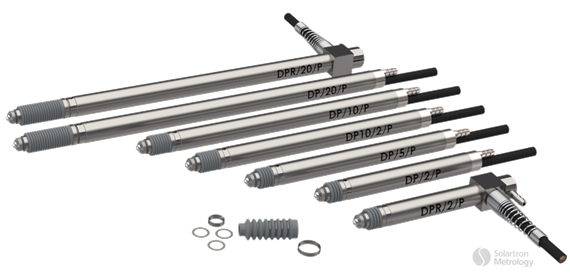

Standard Digital Displacement Sensors | Gauge Probes

Solartron Metrology contact digital gauging probes or displacement sensors provide the gauge builder with the most cost-effective solution for a range of dimensional precision measurement and positioning applications.

A pneumatic displacement sensor (gauge probe) allows the number of parts in the fixture to be reduced resulting in improved reliability and reduced fixture cost. It also allows for fast automatic loading of the part into the gauge as the displacement probe tip can be in the fully ‘retract position’ when this is occurring.

The benefit of using a pneumatic push displacement sensor (gauge probe) compared to a spring push probe is that there is less need to design mechanisms to bring the contact senor tip onto the part being measured thus simplifying the overall gauge design. A pneumatic displacement sensor (gauge probe) allows the number of parts in the fixture to be reduced resulting in improved reliability and reduced fixture cost. It also allows for fast automatic loading of the part into the gauge as the displacement probe tip can be in the fully ‘retract position’ when this is occurring.

The pneumatic digital gauge probe combines the strong features of a conventional linear variable differential transformer (LVDT) with enhanced accuracy. The accuracy specified for the digital senor is total accuracy unlike conventional LVDT’s which specify linearity. Another benefit of the digital displacement sensor (Gauge probe) is the probe requires no set up or adjustment with conditioning electronics like a traditional LVDT because the digital displacement senor provides a precision measurement straight out of the box. Combining multiple sensors using the Orbit Digital Measurement network is easy and data can be read using a Solartron readout or the Gauge Computer Software making system integration simple.

Attention to detail in both design and manufacture of the displacement sensor ensures precision measurement throughout the linear displacement transducer's life.

Solartron Metrology offers a large range of displacement sensors to suit multiple applications with different cable outlets (radial or axial), multiple measuring ranges, different cable types like steel braided which provides additional protection for displacement sensors that are being used in harsh environments.

|

|

|

|

|

|

|

|

|

Digital Automatic Probes (Pneumatic)

Pneumatic Probes are ideal for use in automatic gauging applications or for accessing details that would be difficult or impossible to reach using conventional spring push probes. Some materials such as glass or plastic, for example, require very low tip forces to avoid deformiong the component and contact tip materials that do not leave a mark. Other applications may require height tip forces.

|

|

|

|

|

|

|

|

|

|

|

|

D6JP (2, 5, 12) 6mm - Specification

|

Products |

|

|

|

|

Spring Push Axial Cable ø6h6 |

D6P/2/S |

D6P/5/S |

N/A |

|

Pneumatic Axial Cable ø6h6 |

D6J/2/P |

D6J/5/P |

D6J/12/P |

|

Measurement Performance |

|

Measurement Range (mm) |

2 |

5 |

12 |

|

Accuracy (1) (% of Reading)

|

0.05 |

0.05 |

0.10 |

|

Repeatability (worst case) µm (2)

|

0.15 |

0.15 |

0.50 |

|

Repeatability (typical) µm (3)

|

0.05 |

0.05 |

0.25 |

|

Resolution (µm)

|

0.01 |

0.05 |

0.10 |

|

Pre-travel (mm)

|

0.15 |

0.15 |

0.15 |

|

Post-travel (mm)

|

0.85 |

0.85 |

0.85 |

|

Tip force: (N) at middle of range ±20 %

|

|

|

|

|

Spring Push |

0.7 |

0.7 |

N/A |

|

Pneumatic Jet at 0.9 bar |

0.7 |

0.7 |

N/A |

|

Pneumatic Jet at 1 bar |

N/A |

N/A |

0.7 |

|

Temperature Coefficient % FS / °C

|

0.01 |

0.01 |

0.01 |

|

Environmental |

|

|

Sealing for Probe |

IP65 with gaiter or IP50 without gaiter |

|

Sealing for Probe Interface Electronics |

IP43 for module and TCON |

|

Storage Temperature (ºC) |

-20 to +70 |

|

Probe Operating Temperature with Gaiter (ºC) |

+5 to +80 |

|

Probe Operating Temperature without Gaiter (ºC) |

-10 to +80 |

|

Electronics Operating Temperature (ºC) |

0 to 60 |

|

EMC Emissions |

EN61000-6-3 |

|

EMC Immunity |

EN61000-6-2 |

|

|

|

Material |

|

|

Probe Body |

Stainless Steel |

|

Probe Tip (options) |

Nylon, Ruby, Silicon Nitride, Tungsten Carbide |

|

Gaiter (6) |

Fluoroelastomer or Silicon |

|

Cable |

PUR |

|

Electronics Module |

ABS |

|

Electronics Interface (Orbit®3) |

|

|

Orbit® Interface Options |

USB, Ethernet, RS232 |

|

Reading Rate |

3906 readings per second |

|

Bandwidth of Electronics (Hz) user selectable |

460, 230, 115, 58, 29, 14, 7, 4 |

|

Power |

5±0.25 VDC @ 0.06A typical |

|

|

1) Accuracy 1 µm or % reading, whichever is the greater

2) Obtained by repeated operation against a carbide target with side load applied to the bearing using max-min

3) Obtained by repeated operation against a carbide target standard deviation from average (68%)

6) Fluoroelastomer on 2mm, Silicon on 5 and 12 mm

|

|

|

|

|

|