|

|

|

|

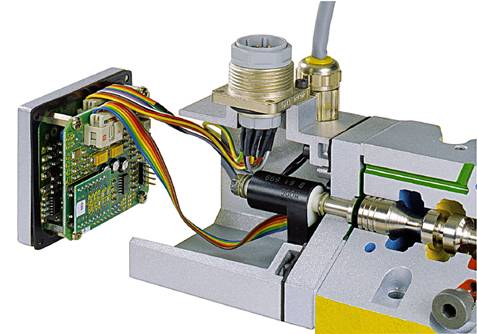

Piston position in hydraulic valves

Servo and proportional valves regulate the volume flow in hydraulic systems. Displacement sensors are necessary for precise control. Inductive displacement sensors mounted on a pressure tube outside the pressure section are used for this. From this position, they measure on the piston through the pressure tube for an exact regulation.

Details

Inductive measuring principle

Low-cost sensor solution in plastic case

High resolution and accuracy

Precise regulation of the piston position

|

|

|

|

|

|

|

Load detection in washing machines

The displacement sensor ILU (Integrated Load and Unbalance Sensor) measures the depression of the suds container when the washing machine is loaded and its deviation during the spinning stage. Due to the inductive measurement principle, the sensor provides absolute position acquisition for static and dynamic processes.

The current load status is continuously displayed and thus enables optimum and maximum loading of the washer drum. The necessary load-dependent detergent quantity is calculated and displayed in parallel.

Details

Inductive measuring principle

Static and dynamically effective measuring principle

Low-cost VIP electronics

Sensor can be integrated in the friction damper

Optimized load status

Improved detergent consumption

|

|

|

|

|

|

|

|

|

MSC710 controller for induSENSOR LVDT

The MSC710 is a single-channel miniature sensor controller for the operation of inductive displacement sensors based on the LVDT principle. Its compact, but rugged design, makes it suitable for both industrial and laboratory applications. Easily accessible and simple to operate, by using DIP-switches. The electronic unit can be matched to a wide range of sensors.

|

|

|

|

|

|

|

|

|

Display units and process indicators

The analog display, DD241PC, has an analog input and is typically used for distance monitoring or for position control. If two analog signals have to be evaluated together, the DD245PC model is available. The DD245PC is ideal for applications such as static thickness measurement, where a new output signal must be calculated from two input signals. The process display DD214NE is used for digital incremental sensors and, like its analog counterpart, can evaluate both signals and output as one signal. The DD202TA is used for displaying revolutions or speed. The DD214NA is used for the position display with SSI output sensors.

Details

Low cost Process indicators

Visualization of various sensor signals

6-digit 7-segment display

For digital or analog displacement signals, speeds and revolutions

|

|

|

|

|

|