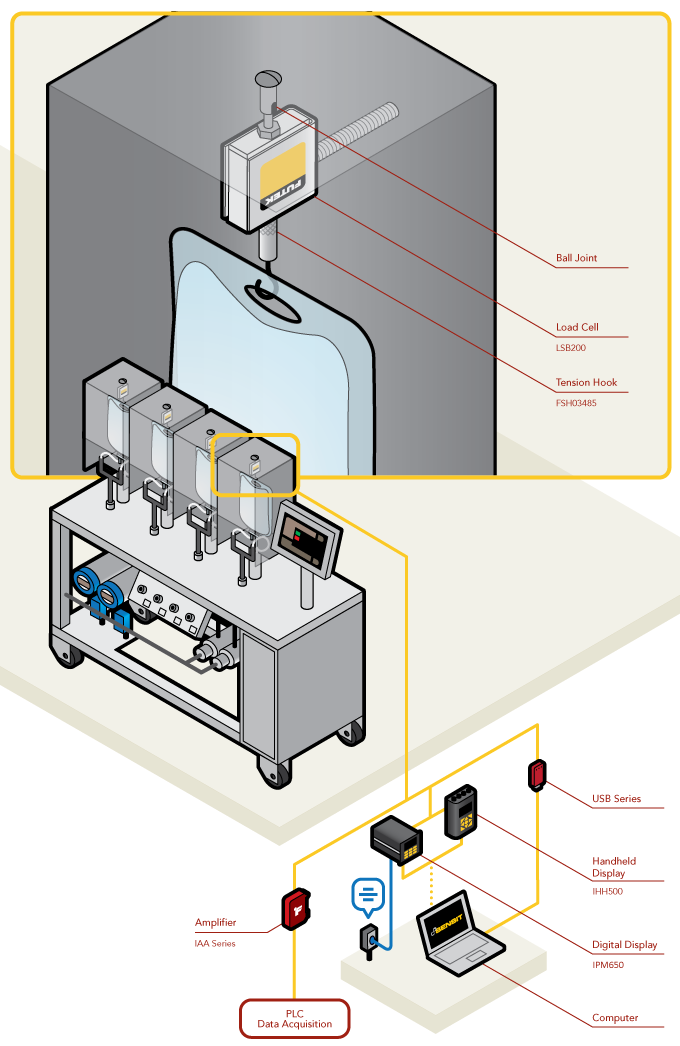

Medical Bag Weighing

How it Works:

- Laboratory equipment, such as dialysis machines or patient monitoring devices, often use test and measurement products either within the machinery or for quality testing.

- In this illustration, FUTEK’s LSB200 Miniature S-Beam Jr. Load Cell has been mounted to the fixture frame of the IV bag weighing apparatus.

- Utilizing a LSB200 accessory hook, the IV bag can then be anchored to the load cell.

- The LSB200, equipped with built-in overload protection, will then measure the tensile force applied, streaming the data to any of the following instruments: IAA Amplifiers, IHH500, IPM650 or USB Solutions.

- If utilizing either of FUTEK's digital displays or USB solutions, options exist for technicians to record results, log and graph data with SENSIT Test and Measurement Software.

|

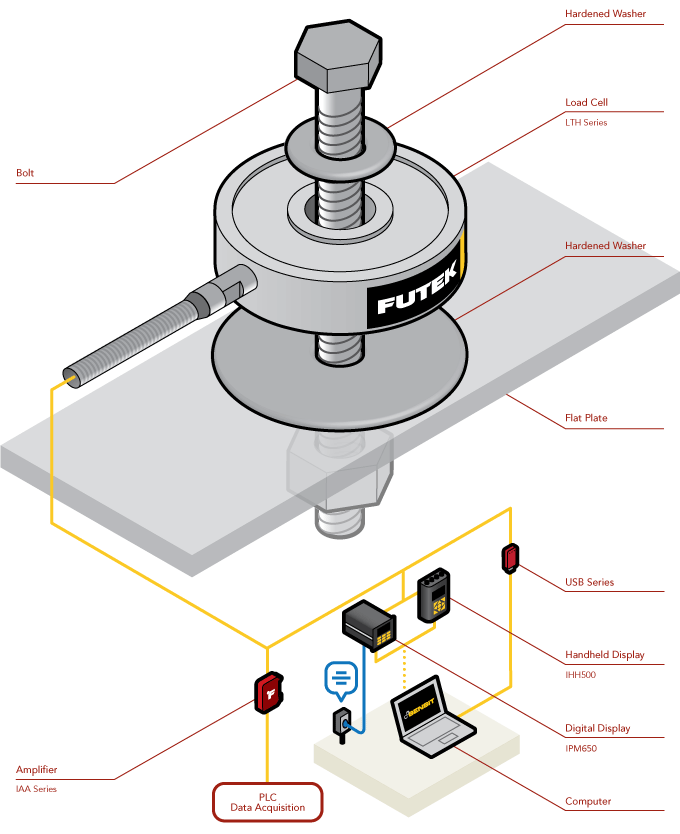

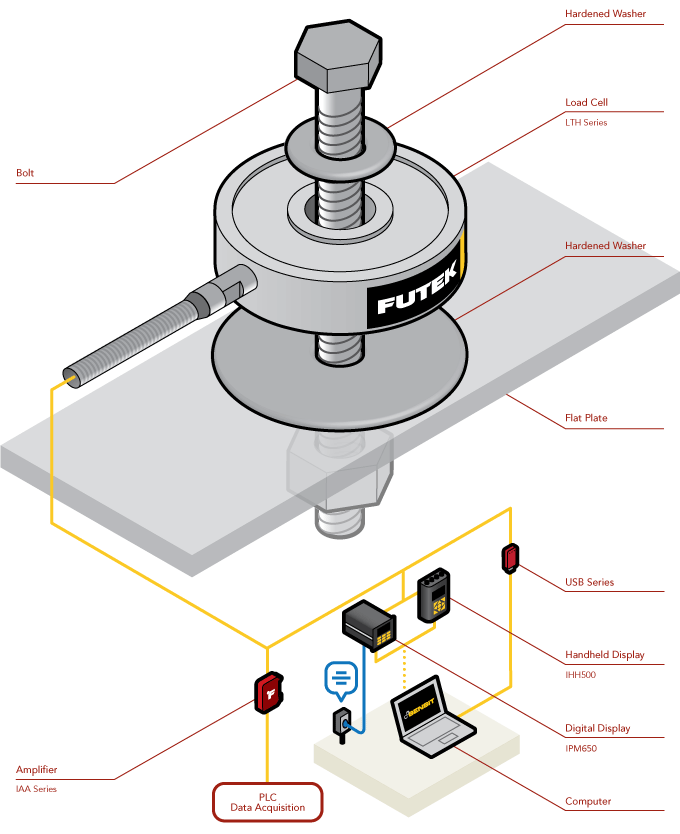

Bolt Fastening

How it Works:

- FUTEK’s LTH Series offers several miniature load cells appropriate for this form of measurement testing.

- In the above application, FUTEK's LTH series load cell is installed between the bolt head and the nut, where it can measure the load as torque is applied.

- Our engineers recommend including a hardened washer between the load cell and the nut to avoid high friction and maintain flatness on the Thru-Hole during tightening and untightening.

- As the operator begins to fasten the bolt, the load cell will measure the force applied.

- This data can be monitored throughout testing via FUTEK’s IPM650 Panel Mount Display or IHH500 Intelligent Digital Hand Held Display; or it can be streamed to a computer via FUTEK’s USB Solutions.

- Operators and engineers can then review this data to verify whether or not they have reached the desired tension on the fastener, stud or bolt via SENSIT™ Test and Measurement Software.

- Overall, the benefits of installing Thru Hole type load cells into your assembly process include: avoiding damage to bearing surfaces, decreased problematic tightening of large bolts, ease in untightening, and simultaneous tightening improvements. You can read more in our white paper on bolt preload auditing.

|

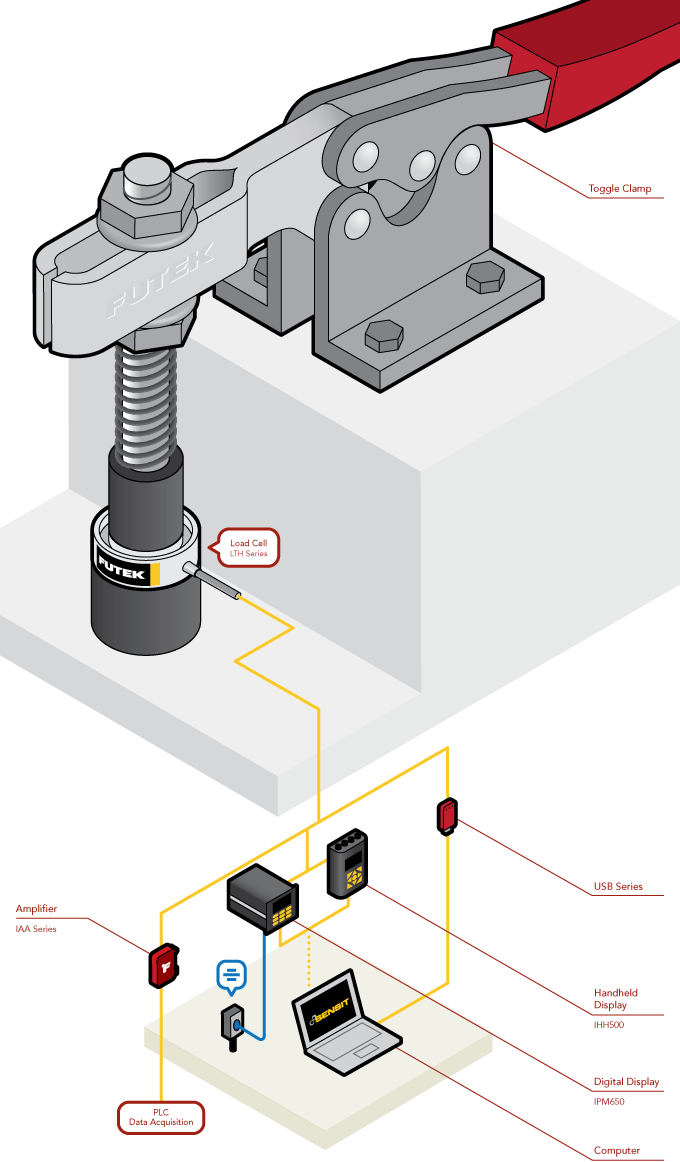

Toggle Force Clamp

How it Works:

- Toggle clamps are commonly used in manufacturing to stabilize and secure objects. In more sensitive applications, the toggle clamps must apply the correct clamping force to ensure a proper seal.

- Load cells can be used to measure the amount of force applied by a toggle clamp to confirm that the clamp is operating within specifications.

- In this application, a toggle clamp is clamping down on FUTEK’s LTH350 Donut/Thru Hole Load Cell. As the clamp applies force to the load cell, the LTH350 senses the applied load and can display the value on FUTEK’s IHH500 Intelligent Digital Hand Held display, FUTEK’s IPM650 Panel Mount Display, or a PC via FUTEK’s USB solutions.

- Pairing the SENSIT™ Test and Measurement Software with any of FUTEK’s instruments provides the user with the ability to data log and live graph the measurements.

|

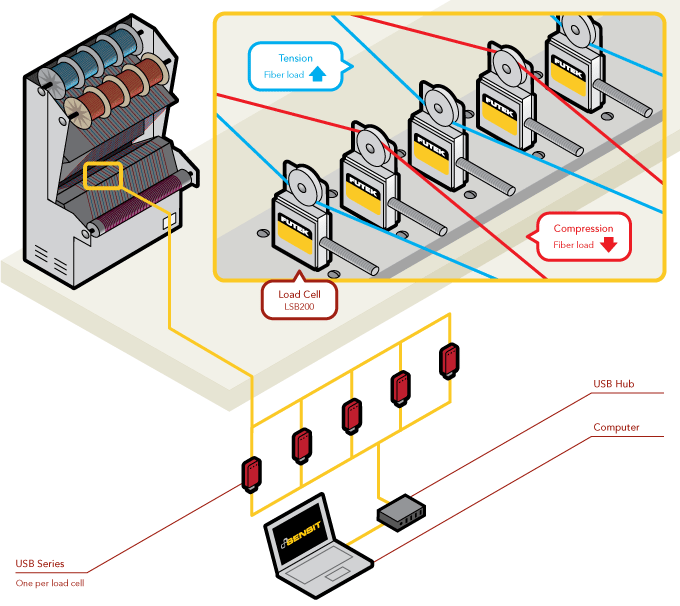

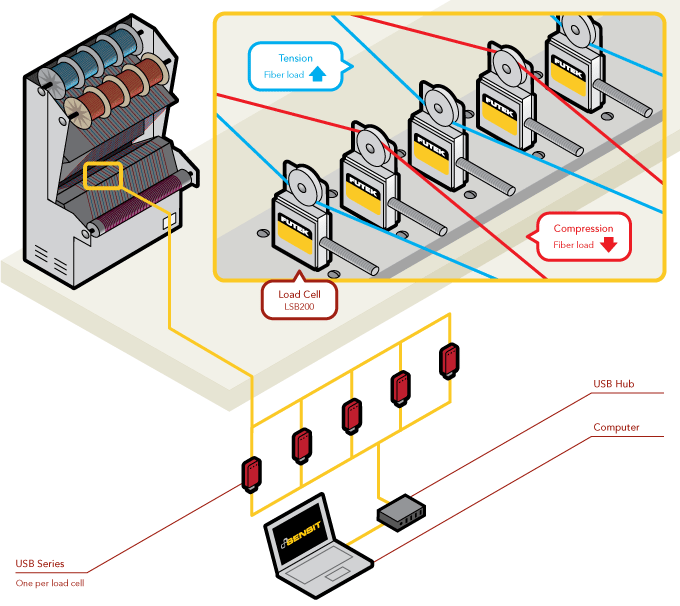

Wire Tension Measurement

How it Works:

- While this type of application may often be associated to the textile industry, wire tension applications are very common in the test and measurement world.

- Utilizing FUTEK's LSB200 Jr. Miniature S-Beam Load Cell provides operators with a space-conscious solution that is equipped with both overload protection and many accessory options.

- To effectively measure the tension/compression per fiber, users utilized a custom pulley mounted to the LSB200. The miniature size of this model makes the integration into various machines simpler. (Note that this model's slender flexure size allows an arrays of LSB200s to be placed closely together.)

- As the operator performs the test, results can then be streamed via FUTEK's USB Solution to a PC.

- This PC can monitor all incoming data through FUTEK’s SENSIT Test and Measurement Software, which allows the operator the ability to monitor the force, view live graphs, and log data for analysis.While this type of application may often be associated to the textile industry, wire tension applications are very common in the test and measurement world.

|

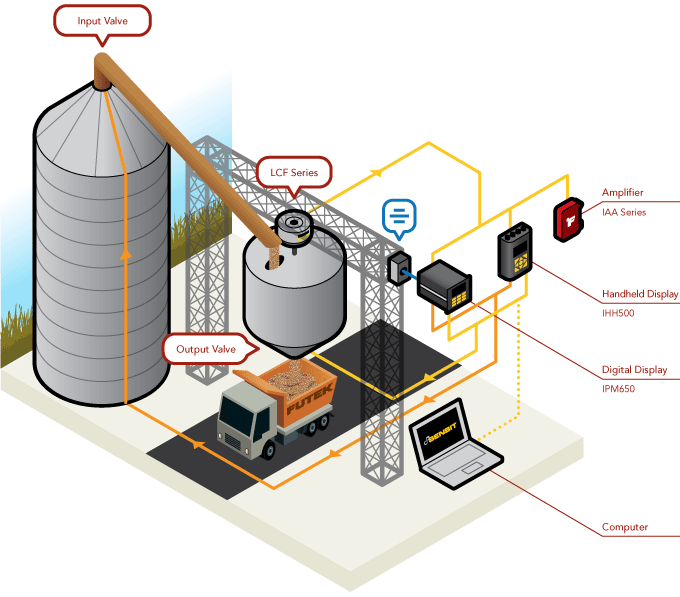

Tank Dispensing

How it Works:

- In this application, a silo is feeding grain into a dispensing container, while an output valve is releasing grain into the carrier truck below.

- To monitor the contents both inputted and outputted, the application engineer has installed a FUTEK LCF Series Load Cell atop the dispensing container.

- As grain is added or removed from the container, FUTEK’s LCF Series Load Cell will measure the distribution ratio of grain as it leaves the container.

- To ensure equal distribution of grain between carrier trucks, FUTEK’s instruments (IHH500 and IPM650) are programmed to trigger the output valve to release an equal quantity each time.

|

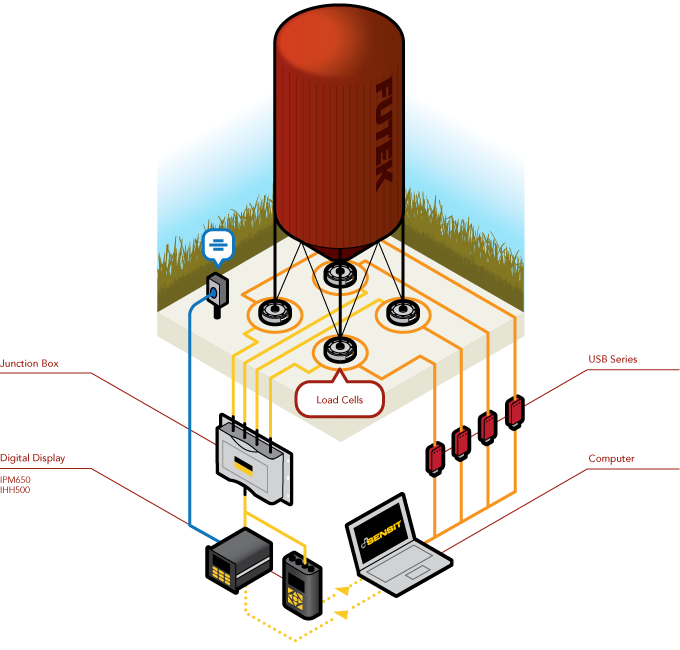

Silo Measurement

How it Works:

- Four LCF Series Pancake Load Cells have been installed at the base of the posts of this silo.

- Depending on the operator's preference, two means of instrumentation can be used to retrieve the measurement data of the silo's contents.

- The first method is to use FUTEK’s USB Solutions. Each LCF Series Pancake Load Cell is paired to a USB Module that can stream live data onto a PC utilizing FUTEK’s SENSIT Test and Measurement Software.

- The second method is to connect each LCF Series Pancake Load Cell to FUTEK’s IAC200 2–4 Channel Summing Junction Box, which will gather the collective load of each load cell and then stream that output to a display (IHH500 or IPM650).

- These methods can also be automated to sound an alarm or send a notification when the weight of the silo reaches a specific mass.

|

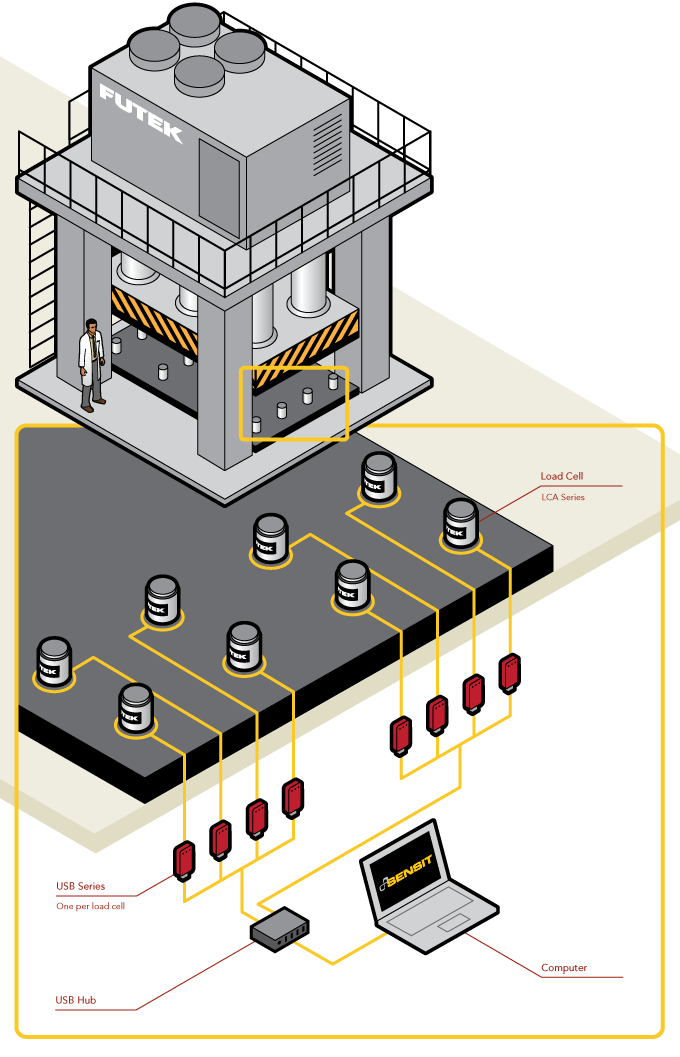

Hydraulic/Pneumatic Press Force

How it Works:

- In this application, engineers have installed several LCA Series Miniature Column Load Cells at the base of this hydraulic press, implementing enough load cells to quantify the full force capacity of the press.

- These load cells have been paired with FUTEK USB modules allowing a live stream of measurements onto the engineer or operator's PC.

- As compressive forces are applied to the LCA Series Load Cells, FUTEK’s USB Solutions in conjunction with FUTEK’s SENSIT™ Test and Measurement Software can verify if the hydraulic press is accurately performing.

|

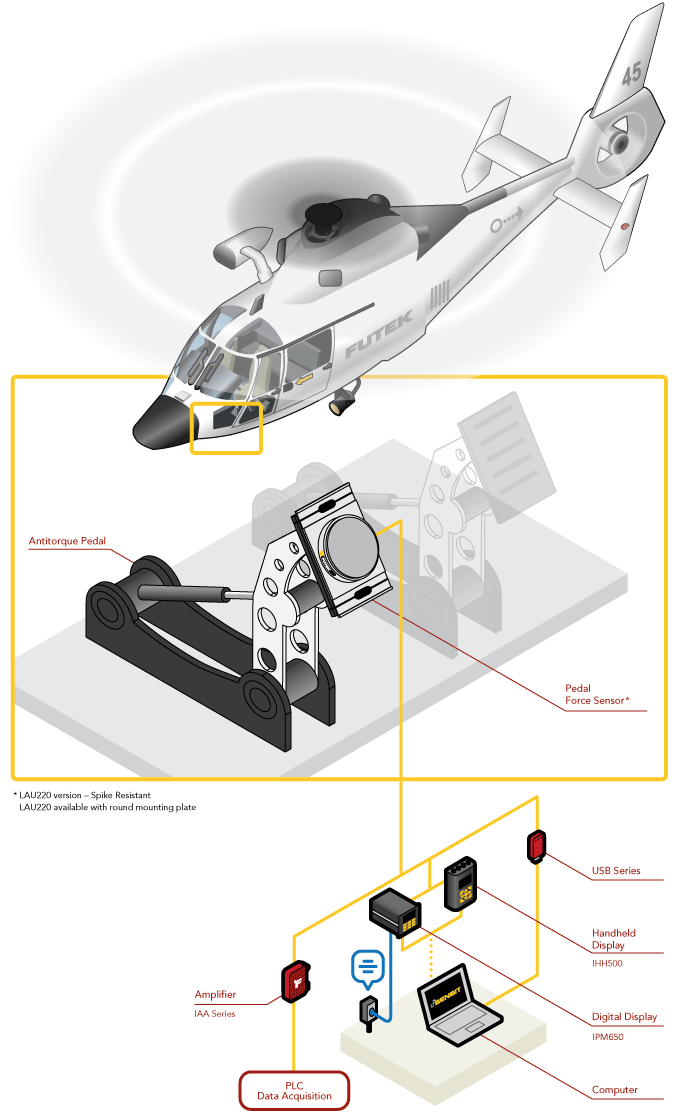

Helicopter Pedal Force Testing

How it Works:

- Flight safety protocols often require rigorous reliability testing. Therefore, quality assurance engineers conduct audits on the anti-torque pedals of each helicopter.

- Utilizing FUTEK's pedal force sensors, these quality assurance engineers can measure the force required to operate each anti-torque pedal as it directs and propels the helicopter through flight.

- These force measures can be read upon a digital display, such as FUTEK's IPM650 Panel Mount Display or IHH500 Intelligent Digital Hand Held Display, or streamed to a PC utilizing FUTEK's USB Solutions.

- Once streamed to a PC, that data can then be monitored by FUTEK's SENSIT Test and Measurement Software. SENSIT can monitor up to 16 channels of measurement readings, as well as live graph and data log.

|

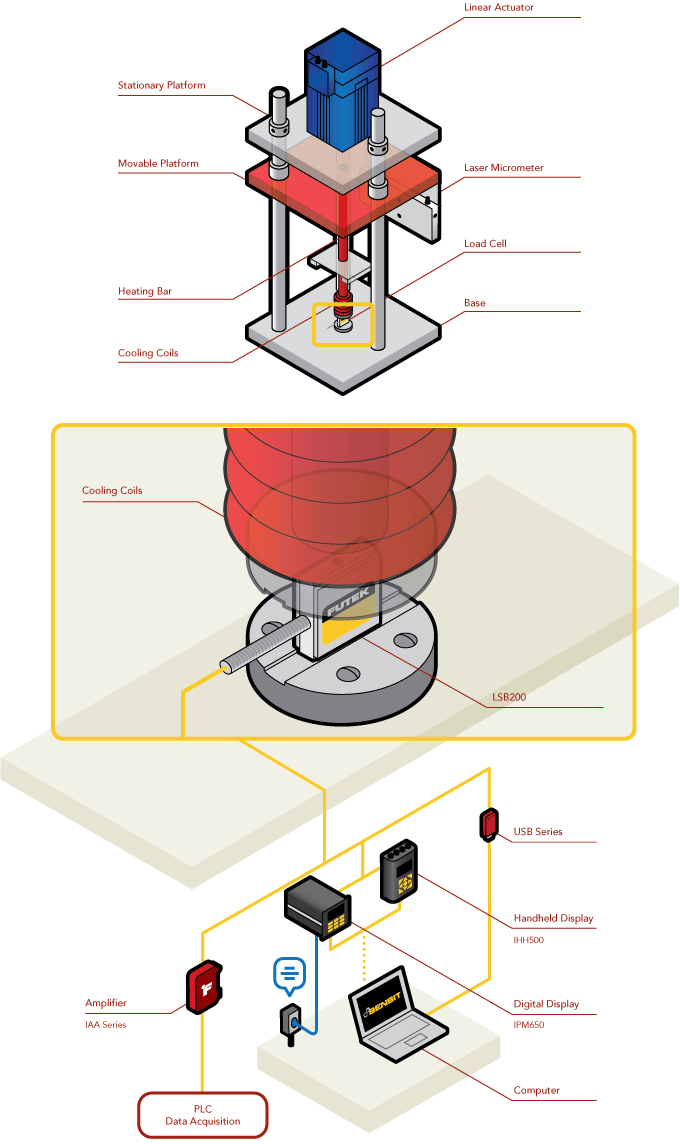

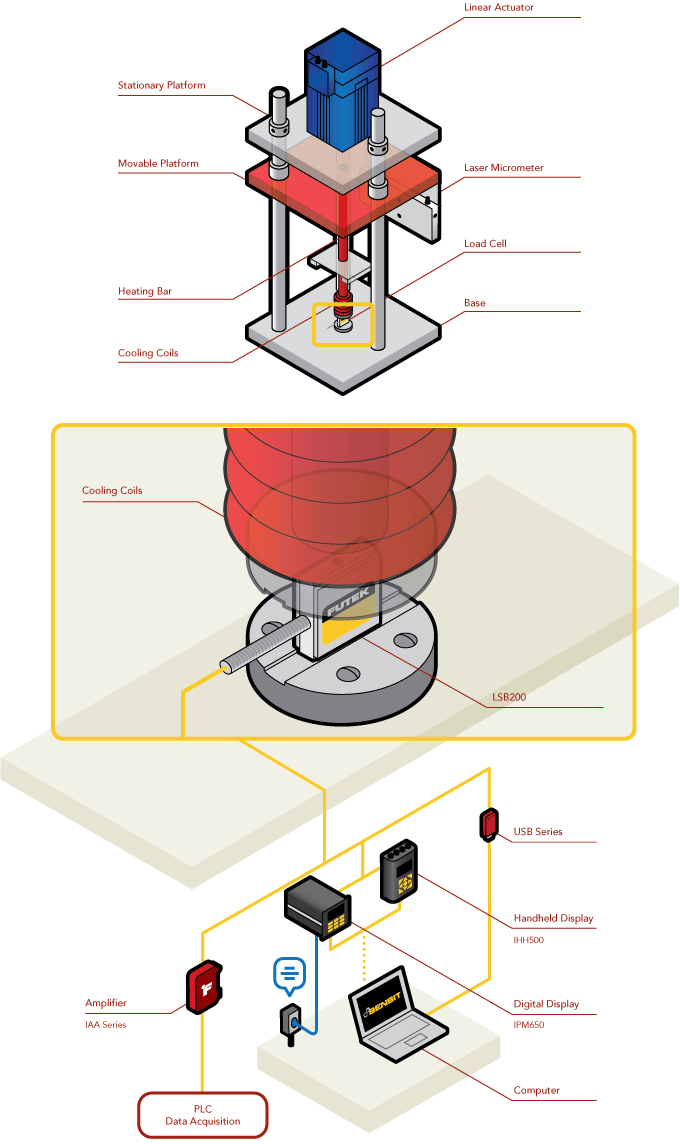

Linear Test Stand

How it Works:

- This application depicts a linear (in-line) low-capacity test stand.

- FUTEK's LSB200 Jr. Miniature S-Beam Load Cell has been installed at the base of the test stand, directly in-line with the heating bar and cooling coils. Due to its sophisticated design, the LSB200 is a suitable option as it can withstand the continuous increase and decrease in temperature without affecting the results.

- As the linear actuator (with an internal motor drive) applies a compressive force upon the load cell, measurement feedback can be monitored through several instrument variations.

- The LSB200's measurements can be streamed directly to a digital display (IPM650 or IHH500), amplified to a PLC using FUTEK's IAA Series analog amplifiers, or streamed directly to a PC utilizing FUTEK's USB Solutions.

- Operators also have the added option of capturing these test results with FUTEK's SENSIT™ Test and Measurement Software. This software features live graphing and data logging capabilities.

|

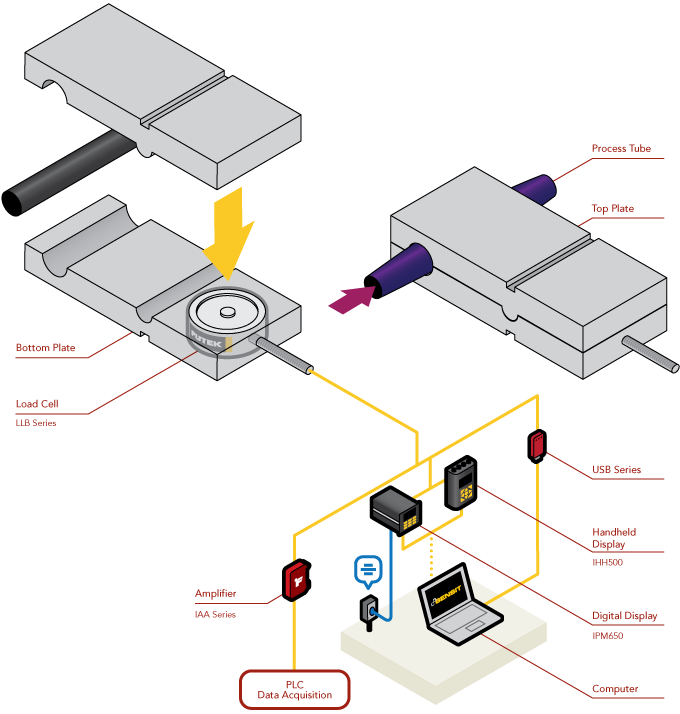

Tube Expansion Measurement

How it Works:

- FUTEK's LLB Series Miniature Load Button is installed between two plates. Also located between these plates is a process tube.

- As fluid flows through the process tube, its diameter expands. The unique design of this plate (pivot points), allows for this expansion to occur.

- As the tube expands, the top plate begins to apply force measurements onto the load button.

- This applied force is then streamed to one of several instrument options - a digital display, an amplifier, or a USB module.

- Both the digital displays as well as the USB module can utilize FUTEK's SENSIT™ Test and Measurement Software to graph and collect the data.

|