|

Delphin's ProfiSignal Go software is intended for users in industry, universities and institutes who are involved in measurement and process data acquisition and evaluation. ProfiSignal Go can be run with any Delphin hardware products. Customers enjoy the user-friendliness of Delphin products and their inexpensive package price for hardware, software and drivers. Delphin has discovered the fastest path to get from sensor to trend output. Users are able to quickly commence measurement data acquisition and evaluation. A range of functions are available to users to meet their measurement requirements. |

|

|

|

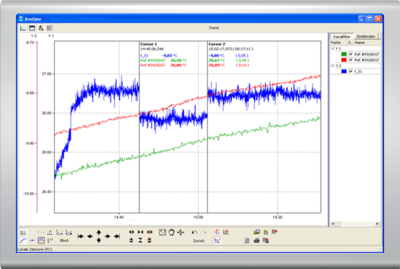

Product highlights • Multichannel measurement data acquisition and evaluation • Users can monitor and evaluate processes both online and offline • Measurement data can be exported to other analysis programs (e. g. Excel, Diadem) • Supports continuous processes with continuous data recording • Supports batch processing with preset start/stops • Network compatible • Parallel running of multiple diagrams with different configurations and channels Hardware and software from a single source Delphin deliver ProfiSignal Go software as a package with the following hardware products: • Expert Key - PC-supported measurement technology • LogMessage - independent data logger • ProfiMessage - modular measurement technology and automation Online analysis ProfiSignal Go is based on online analyses, each with a diagram and channels selected by the user. The online analysis feature is the shortest method available for users to get from sensor to trend output, and the simplest method available for users to analyse measurement data. Potential applications include servicing, mobile applications, error detection and system installation. Online analyses can use trend diagrams (y(t)-diagram), characteristic curves (y(x)-diagram) or logic diagrams. Y(t)-diagrams and trends A trend can process large numbers of channels. A hide/show function enables the display and highlighting of specific channels. A trend can have up to 4 measurement axes. Each axis can be assigned channels. Axes can be extended and compressed and cascaded. Recording data from online analysis Batch data recording Batch recording enables users to use dialogs to define process start/stops. Manual and automatic start/stops are available. Data files are automatically assigned names but users can also manually enter data file names. The saving of batch data is useful for series testing/experiments, fault diagnostics and the monitoring of machinery and production processes. Continuous data recording Data from continuous processes can be monitored online and evaluated offline. Continuous data storage is useful for monitoring continuous production processes, for acquiring data, for long-term trials/experiments etc. Measurement data can be saved in the background while users set up new online analyses and evaluate data from other online analyses. Measurement data analysis ProfiSignal Go is equipped with online and offline modes. The online mode enables users to monitor the state of their current processes. In offline mode, users can access historical data even at high data resolution. Panning is possible along the time axis. Specific data can be visualized by compressing/extending the time and value axes. Users can switch between online and offline modes at the click of the mouse. ProfiSignal Go has an extensive range of analysis functions. These are accessed via buttons on the toolbar. Try and learn about ProfiSignal Go Test channels are channels that require no hardware. They enable users to assign channels to diagrams with sine, square and sawtooth functions. Users are therefore able to set up and experiment with the online analysis feature. The test channels can later be replaced with actual channels using drag and drop. ProfiSignal Go in networks Delphin's measurement hardware can be integrated into existing data networks via LAN-interfaces. Channels can be fed from any number of Message and Expert devices. Users can install ProfiSignal Go on any number of PCs within their company's network. Data can then be evaluated from any authorized PC. Users can also directly connect Message devices to a PC without having to use a network. Interfaces and drivers Delphin products are equipped with drivers and interfaces to enable the import/export of data to external hardware and software. Laboratory equipment (e. g. scales, analysis/output devices) can be connected via USB and RS232/RS485 interfaces. A variety of protocols are available. PROFIBUS and Modbus are used for data transfer between process control systems. The following interfaces are available for third-party software: • LabVIEW™ • DASYLab™ • OPC-Server • OPC Client • Modbus TCP-driver • OCX-driver • GPS-converter |