|

|

Water-dust IP Resistant Technology

|

|

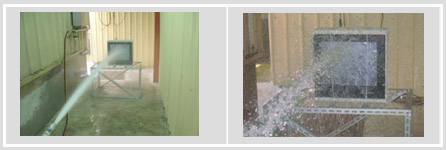

IP sealing is needed in various applications to make the products sealed against liquids, dust or humidity. Winmate is following the standard testing procedures to test the product design.

We provide various levels of mechanical IP dust & water resistant design and offer ruggedized industrial flat panel LCD displays. These Ruggedized LCD products are also designed for high reliability, shock and vibration tolerance, survival of high temperature, and corrosive environments. External materials like dust/ water can be very destructive to any type of equipment over time.

|

|

__________________________________________________________________________________________________________ |

|

|

Table of IP Sealing Ratings

|

First Number (Protection against solid objects) |

Definition |

Second number (Protection against liquids) |

Definition |

|

No protection |

|

No protection |

|

Protected against solids objects over 50 mm (e.g. accidental touch by Hands) |

|

Protected against vertically falling drops of water |

|

Protected against solids objects over 12 mm (e.g. fingers) |

|

Protected against directsprays up to 15 degree from the vertical |

|

Protected against solids objects over 2.5 mm (e.g. tools and wires) |

|

Protected against direct sprays up to 60 degree from the vertical |

|

Protected against solids objects over 1mm (e.g.tools, wires and small wires |

|

Protected against sprays from all directions, limited ingress permitted |

|

Protected against dust,limited ingress (no harmful deposit) |

|

Protected against low pressure jets if water from all directions,limited ingress permitted |

|

Totally protected against dust |

|

Protected against strong jets of water e.g. for use on shipdecks - limited ingress permitted |

|

|

|

|

Protected against the effects of temporary immersion between 15 cm and 1m. Duration of test 30 minutes |

|

|

|

|

Protected against long periods of immersion under pressure |

|

|

__________________________________________________________________________________________________________ |

|

|

NEMA Enclosure Rating and Comparison to IP Code

NEMA (National Electrical Manufacturers Association) sets the industry standards in the USA for electrical equipment enclosures. In non-hazardous locations, there are several different NEMA ratings for specific enclosure types, their applications, and the environmental conditions they are designed to protect against when completely and properly installed.

The following provides an overview of the NEMA types. For complete definitions, descriptions, and test criteria, see the National Electrical Manufacturers Association (NEMA) Standards Publication No. 250. The European Standards are determined by the Institute of Petroleum and are sometimes referred to as Ingress Protection (IP) numbers. The standards are listed below.

|

|

__________________________________________________________________________________________________________ |

|

|

Table of NEMA Enclosure Rating and Comparison to IP Code

|

NEMA Enclosure Rating |

Description |

IP Classification Code |

|

1 |

NEMA 1- Enclosures constructed for indoor use to provide a degree of protection to personnel against incidental contact with the enclosed equipment and to provide a degree of protection against falling dirt. |

IP20 |

|

2 |

NEMA 2- Same as NEMA 1 including protection against dripping and light splashing of liquids. |

IP21 |

|

3 |

NEMA 3- Enclosures constructed for either indoor or outdoor use to provide a degree of protection to personnel against incidental contact with the enclosed equipment; to provide a degree of protection against falling dirt, rain, sleet, snow, and windblown dust; and that will be undamaged by the external formation of ice on the enclosure. |

IP54 |

|

3R |

NEMA 3R- Same as NEMA 3 excluding protection against windblown dust |

IP24 |

|

3S |

NEMA 3S- Enclosures constructed for either indoor or outdoor use to provide a degree of protection to personnel against incidental contact with the enclosed equipment; to provide a degree of protection against falling dirt, rain, sleet, snow, and windblown dust; and in which the external mechanism(s) remain operable when ice laden. |

IP54 |

|

4, 4X |

NEMA 4- Enclosures constructed for either indoor or outdoor use to provide a degree of protection to personnel against incidental contact with the enclosed equipment; to provide a degree of protection against falling dirt, rain, sleet, snow, windblown dust, splashing water, and hose-directed water; and that will be undamaged by the external information of ice on the enclosure.

NEMA 4X- Same as NEMA 4 including protection against corrosion. |

IP56

IP65

IP66 |

|

5 |

NEMA 5- Enclosures constructed for indoor use to provide a degree of protection to personnel against incidental contact with the enclosed equipment; to provide a degree of protection against falling dirt; against settling airborne dust, lint, fibers, and to provide a degree of protection against dripping and light splashing of liquids. |

IP52 |

|

6,6P |

NEMA 6- Enclosures constructed for either indoor or outdoor use to provide a degree of protection to personnel against incidental contact with the enclosed equipment; toprovide a degree of protection against falling dirt; against hose-directed water and the entry of water during occasional temporary submersion at a limited depth; and that will be undamaged by the external formation of ice on the enclosure.

NEMA 6P- Same as NEMA 6 including protection against the entry of water during prolonged submersion at a limited depth. |

Ip67 |

|

12, 12K |

NE1V1A 12- Enclosures constructed (without knockouts) for indoor use to provide a degree of protection to personnel against incidental contact with the enclosed equipment; to provide a degree of protection against falling dirt; against circulating dust, lint, fibers, and against dripping and light splashing of liquids.

NEMA 12K- Same as NEMA 12 including enclosures constructed with knockouts |

IP52 |

|

13 |

NEVA 13 - Enclosures constructed for indoor use to provide a degree of protection to personnel against incidental contact with the enclosed equipment; to provide a degree of protection against falling dirt; against circulating dust, lint, fibers, and against the spraying, splashing, and seepage of water, oil, and non-corrosive coolants. |

IP54 |

|

|

__________________________________________________________________________________________________________ |

|

|

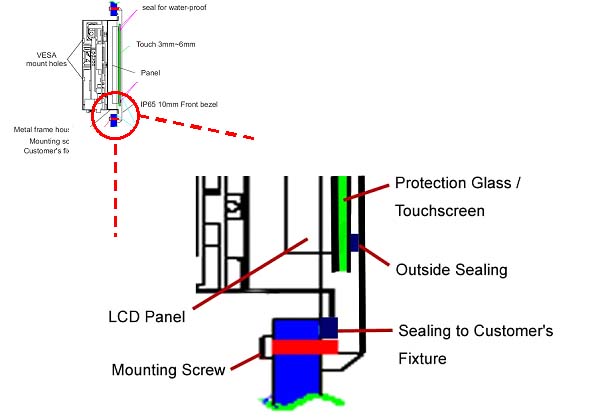

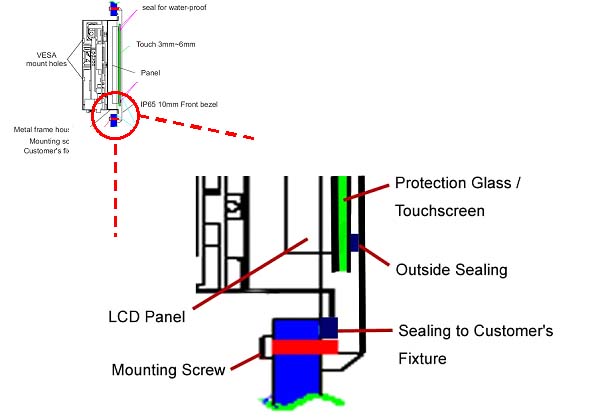

Technology / Function Diagrams

On a product there are many different possibilities of sealing. The most typical sealing is the front sealing. After mounting the product is sealed for dust and water (depend on the tested grade).

Besides the front side sealing, there are also other parts as the connectors, the back side, from the top and the full sealing, depending on the application.

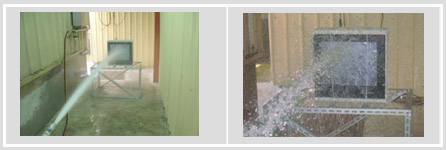

We are doing related to the degree of the sealing the related tests with the products and check if there is any water, dust or dirt passing our sealing design.

1. IP6X Test -- Test for protection against Dust

2. IPX6 Test -- Test for protection against Water

3. IP65 Test -- Test for protection against Water&Dust

4. IP4X Test -- Test for protection against Dust

5. IPX4 Test -- Test for protection against Water

The Sealing concept of Winmate contains the following product sealings:

-

Glass or touchscreen to front bezel

-

Internal dust sealing from LCD to the glass or touchscreen

-

Prepared sealing for mounting to the equipment

Besides the sealing to water, also other liquids for cleaning, disinfection or saltwater are possible environments, witch influences the choice of the high tech sealing material and maybe the design concept how to seal.

Also the direct sunlight need to be considered in this choice, as UV-light can destroy the polymer structure of most sealing materials.

The right choice of the material is a core competence of Winmate’ s

engineering and design capabilities.

|

|

__________________________________________________________________________________________________________ |

|

|

Features & Benefits

-

Reliable and long lifetime design

-

Versatile IP grade mechanical design with full range from 6.4” to 20.1”

-

IP65 with 10 mm front bezel and tempered glass protection

-

Available for panel mount and rack mount type

-

Integration with thermal and anti-vibration system design capability

|

|

__________________________________________________________________________________________________________ |

|

|

Applications

-

Industrial & factory automation

-

Heavy duty vehicles

-

Outdoor Kiosk

-

Swimming and SPA pool Kiosk

-

Toilet AD display

-

Medical Equipment

|

|

__________________________________________________________________________________________________________ |

|

|

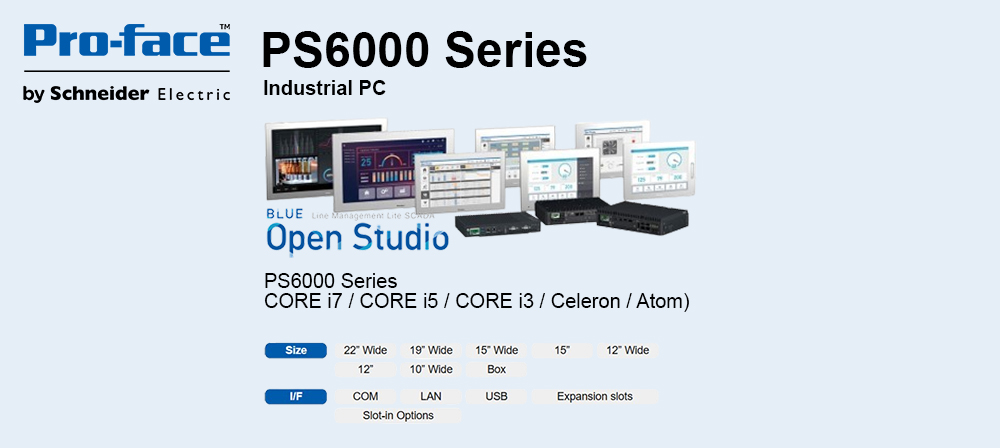

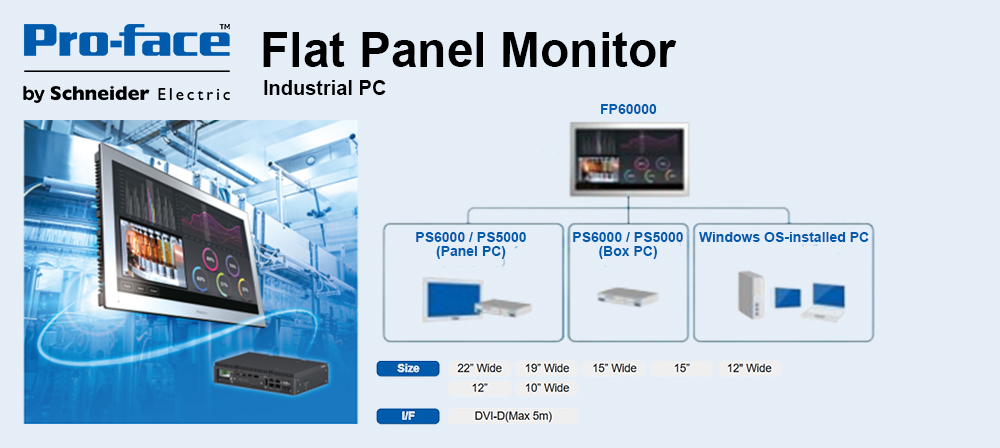

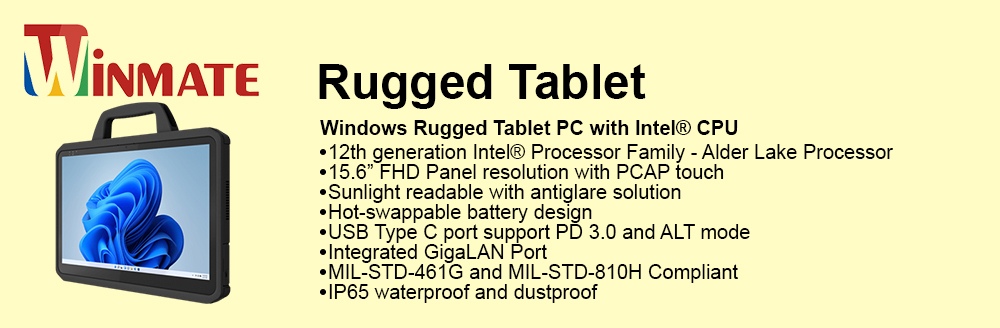

Products use this technology

Our "Water-dust IP resistant" technology are now available for all LCD and Panel PC product line solutions. Please contact with sales for more detail information.

|

|

|

|

|

|

Product & Technology News

N2930 Stainless B Series Panel PC

Application Selector

Download Catalogue

|