|

||||||

Understanding Non Repeat

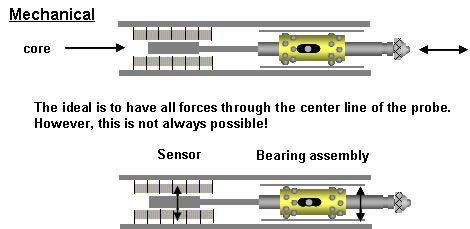

A test that can not be reliably repeated is of little value. Gauge R&R (repeatability & reproducibility) is one of the most important aspects of a gauging fixture. Good repeatability is one of he most difficult functions to achieve when building a gauging probe, which is why Solartron has invested so much in the Manufacture of Bearings and shielding against electrical interference. The failure of a Gauging Probe to provide good repeatability comes primarily from two sources, mechanical free movement within the probe and electrical noise.

Determining Non Repeat

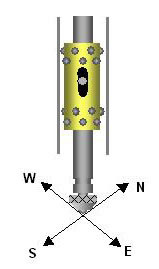

It is relatively simple to determine good repeatability from a gauging probe by gently lifting the tip and allowing it to gently return to its start position. A number of probe manufacturers use this method or fail to quote non repeat at all. Unfortunately, apart from a few laboratory applications, such as Gauge Block Calibration, the vast majority of applications are a lot more demanding. The method used to determine non-repeat at Solartron Metrology is very demanding but relative to both laboratory and shop floor applications. A reading is taken with the probe tip resting on a datum point. The tip is then raised while exerting a side force of 80-100 grm and returned to the start point. A second reading is taken to determine the deviation from the start point. This process is repeated at the four points of the compass. The maximum difference in the readings between the four lifting cycles represents non-repeatability.

Understanding Non Repeat - Electrical

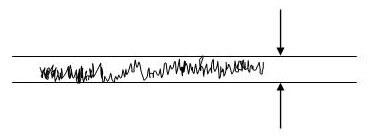

Electrical noise or cross talk can have a significant negative effect to both Non Repeat and Accuracy when using any conventional LVDT or Half Bridge Gauging Probe.

Noise levels are often related to the number of probes installed and can have a significant effect on gauge R&R. Solartron Metrology takes special care to ensure that with its shielded construction, its Analogue Gauging Probes are as immune as possible to external electrical interference. However, as a component no LVDT or Half Bridge Gauging Probe can, on its own, obtain CE certification for noise immunity or emission. It is the responsibility of the system builder to obtain CE certification for any complete system that incorporates Analogue Gauging probes. Solartron Metrology’s Orbit® Network and Digital Gauging Probes provide improved Gauge R&R through cleaner signals and better electrical noise immunity: Solartron Digital Probes Conform to EN 61000-6-2 and have been independently approved for CE certification.

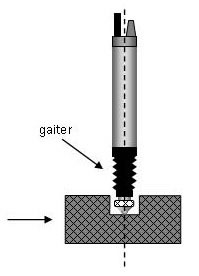

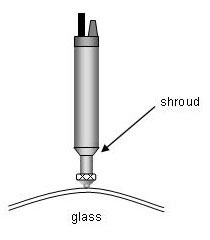

Understanding Non Repeat - Pneumatic Gauging Probes

|

||||||