|

In assembly lines, torque wrenches enable fasteners (screws, nuts, and bolts) to be tightened to exactly the right torque specification, allowing the product (i.e. car) to function for several years without fastener damage or become hard to remove. In commercial applications such as appliance repair, it allows for technicians to fix them while avoiding over-torquing the fasteners and damaging threads.

However, torque is only useful for its accuracy. Normally after 5,000 cycles, it requires recalibration to ensure it is still reliable. Many people rely only on the original factory calibration and ignore the fact that torque wrenches require yearly calibration after wear and tear caused by regular usage over time.

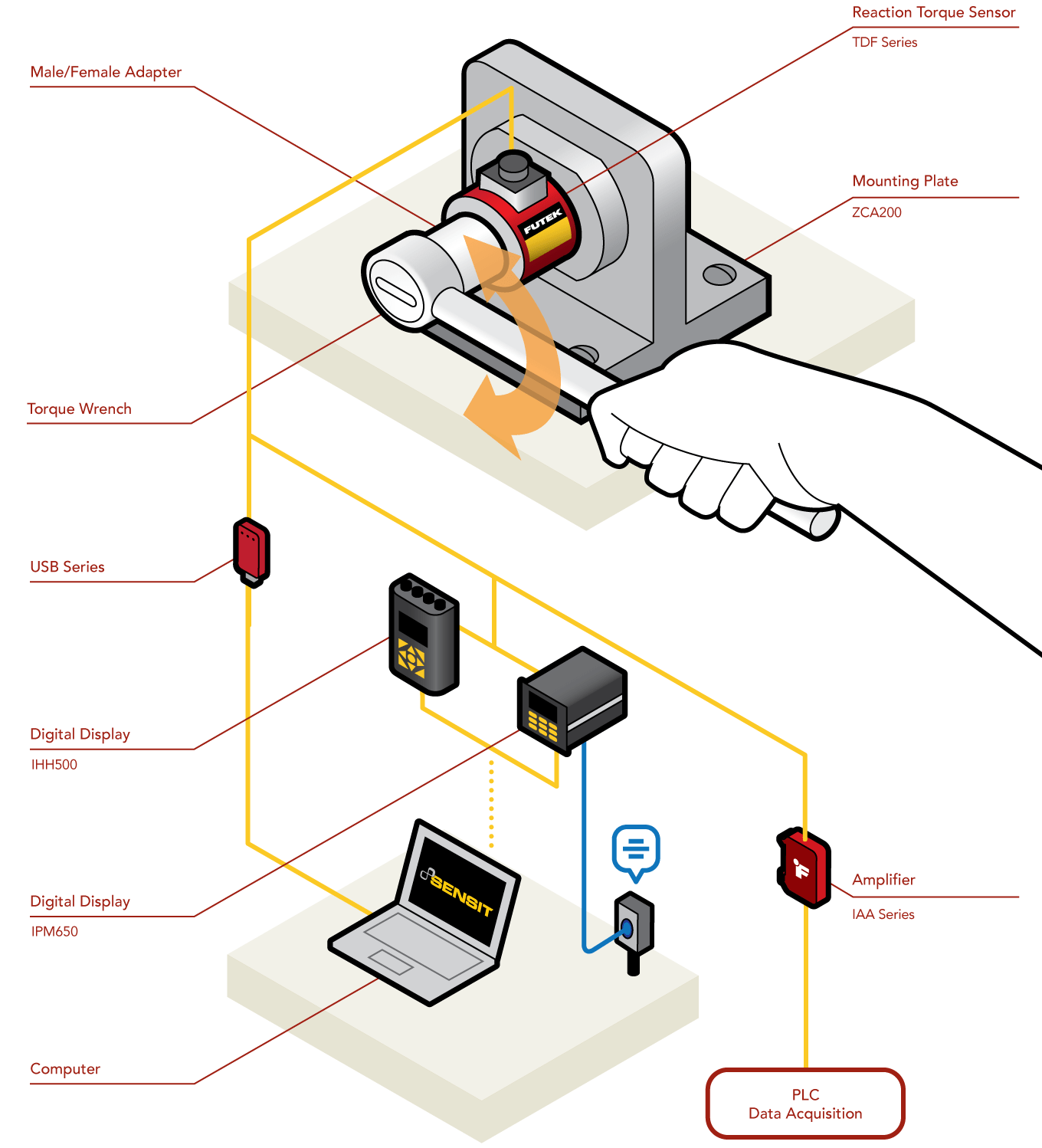

Reaction Torque Sensors are frequently used as auditing and torque wrench calibration tools. This application is utilizing FUTEK’s TDF Torque Sensor to verify the precision of a torque wrench. FUTEK is equipped with A2LA accredited calibration lab to support critical applications related to torque wrench calibration tool.

Torque Wrench Calibration is an adjustment or set of corrections that are performed on a torque transducer to make sure that the sensor operates as accurately, or error-free, as possible.

|