|

|

|

| |

G2130, G2140, G2150 Crosby Safety Shackles

|

| |

|

|

| |

Description

G2130 Bow Shackle & G2150 D Shackle

Capacities 1/3 thru 150 metric tons, grade 6. Capacities 1/3 thru 150 metric tons, grade 6. Working Load Limit and grade “6” permanently shown on every shackle. Working Load Limit and grade “6” permanently shown on every shackle. Forged ¯ Quenched and Tempered, with alloy pins. Forged ¯ Quenched and Tempered, with alloy pins. Hot Dip galvanized or Self Colored. (85, 120, and 150-metric ton shackles are all hot dip galvanized bows and the bolts are Dimetcoted® and painted red) Hot Dip galvanized or Self Colored. (85, 120, and 150-metric ton shackles are all hot dip galvanized bows and the bolts are Dimetcoted® and painted red) Fatigue rated (1/3t - 55t). Fatigue rated (1/3t - 55t). Shackles 25t and larger are RFID EQUIPPED. Shackles 25t and larger are RFID EQUIPPED. Approved for use at -40 degree C (-40 degree F) to 204 degree C (400 degree F). Approved for use at -40 degree C (-40 degree F) to 204 degree C (400 degree F). 2t through 25t bow and bolt are Certified to meet charpy impact testing of 42joules (31 ft-Ibs.) min. ave. at -20 degree C (-4 degree F) 2t through 25t bow and bolt are Certified to meet charpy impact testing of 42joules (31 ft-Ibs.) min. ave. at -20 degree C (-4 degree F) Meets or exceeds all requirements of ASME B30.26. Meets or exceeds all requirements of ASME B30.26. Sizes 1/2t-25t meet the performance requirements of EN13889:2003. Sizes 1/2t-25t meet the performance requirements of EN13889:2003. Shackles 55 metric tons and smaller can be furnished proof tested with certificates to designated standards, such as ABS, DNV, Lloyds, or other certification when requested at time of order. Shackles 55 metric tons and smaller can be furnished proof tested with certificates to designated standards, such as ABS, DNV, Lloyds, or other certification when requested at time of order. Shackles 120 metric tons and larger are proof tested, Magnetic Particle Inspected and provided with Serialized Pin and Bow. Shackles 120 metric tons and larger are proof tested, Magnetic Particle Inspected and provided with Serialized Pin and Bow. Type Approval and certification in accordance with ABS 2006 Steel Vessel Rules 1-1-17.7, and ABS Guide for Certification of Cranes. Type Approval and certification in accordance with ABS 2006 Steel Vessel Rules 1-1-17.7, and ABS Guide for Certification of Cranes. 3.1 Certification as standard available for charpy and statistical proof test up to 25 tons to DNV2.7-1 and EN13889. 3.1 Certification as standard available for charpy and statistical proof test up to 25 tons to DNV2.7-1 and EN13889. Crosby 2t through 25t G2130 anchor shackles are type approved to DNV Certification Crosby 2t through 25t G2130 anchor shackles are type approved to DNV Certification Notes 2.7-1- Offshore Containers. These Crosby shackles are statistical proof and impact tested. The tests are conducted by Crosby and 3.1 test certification is available upon request.. Notes 2.7-1- Offshore Containers. These Crosby shackles are statistical proof and impact tested. The tests are conducted by Crosby and 3.1 test certification is available upon request.. All other 2130 and all 2150 shackles can meet charpy requirements of 42 joules (31 ft-Lbs) avg at -20 degree C (-4 degree F) upon special request. All other 2130 and all 2150 shackles can meet charpy requirements of 42 joules (31 ft-Lbs) avg at -20 degree C (-4 degree F) upon special request.

G2140 Bow Shackle

Quenched and Tempered. Quenched and Tempered. Alloy bows, Alloy bolts. Alloy bows, Alloy bolts. Forged Alloy Steel 30 thru 175 metric tons. Cast Alloy Steel 200 thru 400 metric tons. Meets performance requirements of Grade 8 shackles. Forged Alloy Steel 30 thru 175 metric tons. Cast Alloy Steel 200 thru 400 metric tons. Meets performance requirements of Grade 8 shackles. Working Load Limit is permanently shown on every shackle. Working Load Limit is permanently shown on every shackle. 30, 40, 55, and 85 metric ton shackle bows are available galvanized or self colored with pins that are galvanized and painted red. 30, 40, 55, and 85 metric ton shackle bows are available galvanized or self colored with pins that are galvanized and painted red. 120, 150, 175 metric ton shackle bows are hot-dip galvanized; pins are Dimetcoted® and painted red. 120, 150, 175 metric ton shackle bows are hot-dip galvanized; pins are Dimetcoted® and painted red. 200, 250, 300 and 400 metric ton shackle bows are Dimetcoted®; pins are Dimetcoted® and painted red. 200, 250, 300 and 400 metric ton shackle bows are Dimetcoted®; pins are Dimetcoted® and painted red. All sizes are RFID EQUIPPED. All sizes are RFID EQUIPPED. Approved for use at -40 degree C (-40 degree F) to 204 degree C (400 degree F). Approved for use at -40 degree C (-40 degree F) to 204 degree C (400 degree F). Shackles are Quenched and Tempered and can meet DNV impact requirements of 42 joules (31 ft-lbs.) at -20 degree C (-4 degree F). Shackles are Quenched and Tempered and can meet DNV impact requirements of 42 joules (31 ft-lbs.) at -20 degree C (-4 degree F). All sizes are individually proof tested to 2.0 times the Working Load Limit. All sizes are individually proof tested to 2.0 times the Working Load Limit. Shackles 200 metric tons and larger are provided with serialised Pin and Bow, Material Certification (Chemical), Magnetic Particle Inspected. Please note that certification must be requested at time of order. Shackles 200 metric tons and larger are provided with serialised Pin and Bow, Material Certification (Chemical), Magnetic Particle Inspected. Please note that certification must be requested at time of order. Meets or exceeds all requirements of ASME B30.26 including identification, ductility, design factor, proof load and temperature requirements. Importantly, these shackles meet other critical performance requirements including fatigue life, impact properties and material traceability, not addressed by ASME B30.26. Meets or exceeds all requirements of ASME B30.26 including identification, ductility, design factor, proof load and temperature requirements. Importantly, these shackles meet other critical performance requirements including fatigue life, impact properties and material traceability, not addressed by ASME B30.26. Type Approval and certification in accordance with ABS 2006 Steel Vessel Rules 1-1-17.7, and ABS Guide for Certification of Cranes. Type Approval and certification in accordance with ABS 2006 Steel Vessel Rules 1-1-17.7, and ABS Guide for Certification of Cranes.

|

| |

Features

Alloy bolts and bows Alloy bolts and bows Bow shackles from 0.3te to 400te Bow shackles from 0.3te to 400te Buy as an accessory with or without our link load cells Buy as an accessory with or without our link load cells D shackles from 0.5te to 85te D shackles from 0.5te to 85te Manufactured by Crosby Manufactured by Crosby Quenched and Tempered Quenched and Tempered Supplied with full Crosby traceability Supplied with full Crosby traceability

|

| |

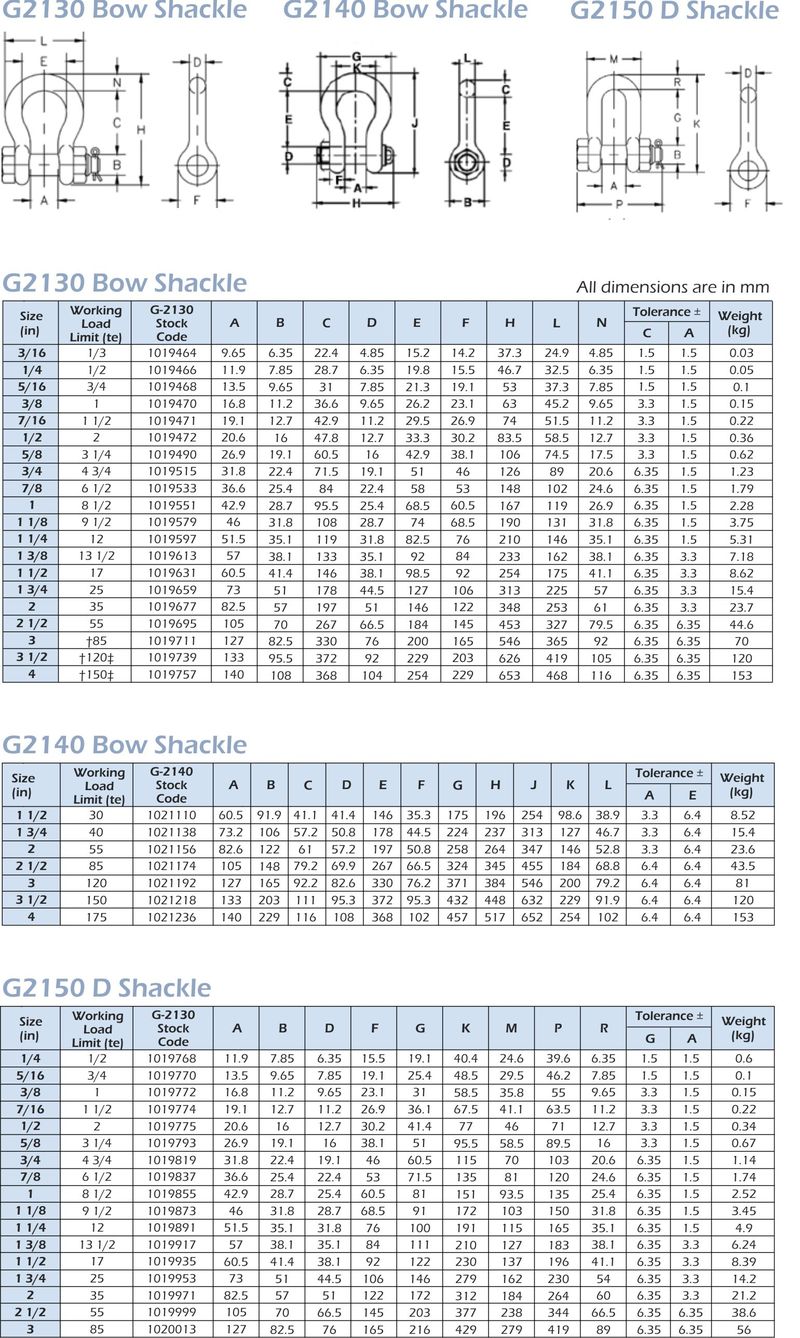

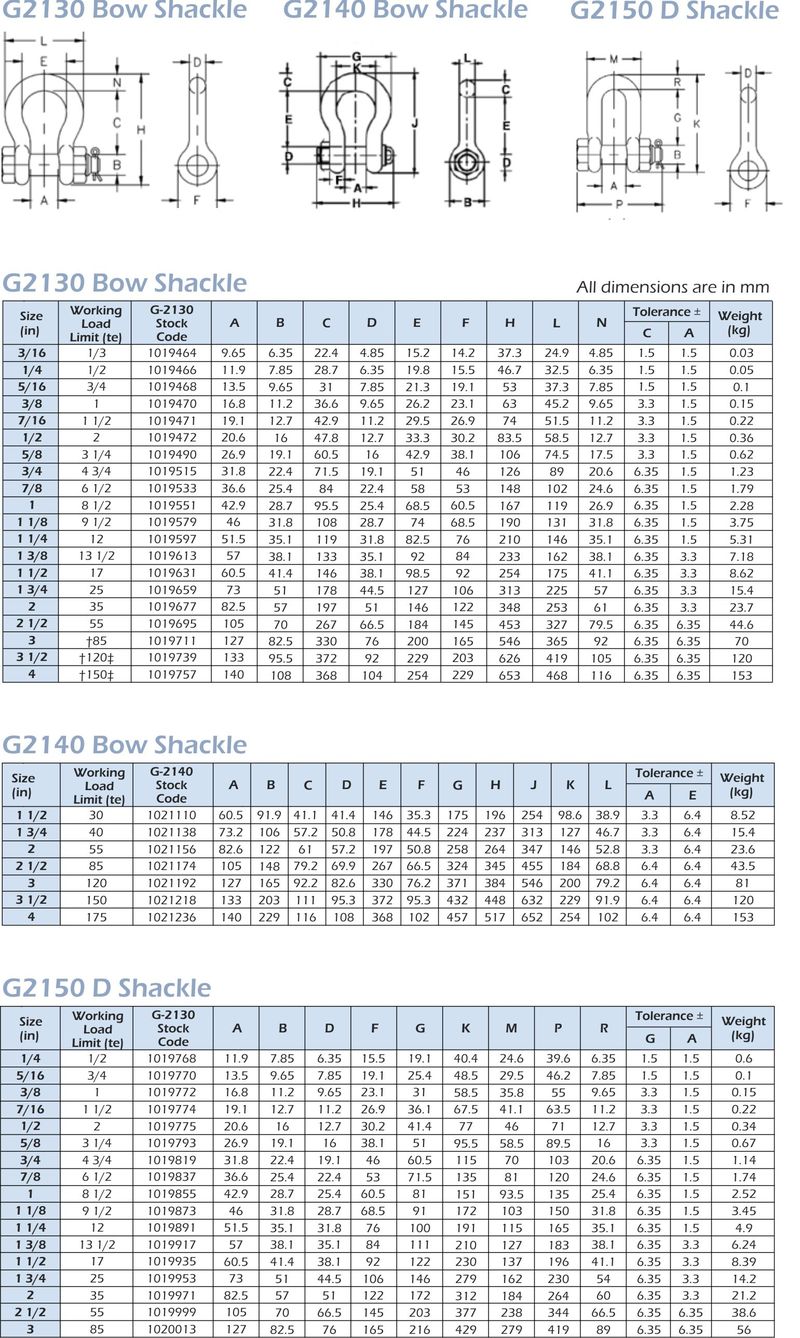

Dimensions

|

| |

Options

G2130 Bow Shackles - 0.33 tonnes to 150 tonnes G2130 Bow Shackles - 0.33 tonnes to 150 tonnes G2140 Bow Shackles - 30 tonnes to 400 tonnes G2140 Bow Shackles - 30 tonnes to 400 tonnes G2150 D Shackles - 0.5 tonnes to 85 tonnes G2150 D Shackles - 0.5 tonnes to 85 tonnes

|

| |

Applications

Lifting Lifting Cable tension Cable tension Mooring Mooring Pull testing Pull testing

|

| |

| |

|

|

Capacities 1/3 thru 150 metric tons, grade 6.

Capacities 1/3 thru 150 metric tons, grade 6.