|

|

|

TM / Surface Variation Detector

|

|

|

|

Fine wire counterpart (Measurement object diameter: Φ 0.02 to 3 mm, 0.02 to 5 mm) |

|

Model No. |

TM-503W |

TM-1100XY |

TM-1003W |

TM-1104W |

|

CAD file |

Power supply unit (PW-02)

[*1] |

|

Power supply unit (PW-01)

[*1] |

|

Power supply unit (PW-02)

[*1] |

|

Power supply unit (PW-01)

[*1] |

|

|

Direction of detection |

3 directions |

2 directions |

3 directions |

4 directions |

|

Measurement method |

Double slit infrared LED projection type |

|

Adaptive work outer diameter |

φ0.02 to 3 mm |

φ0.02 to 10 mm |

φ0.02 to 5 mm |

φ0.02 to 10 mm |

|

Unevenness detection range |

0.02 to 1 mm |

|

Unevenness detection accuracy |

Maximum setting within ± 1% |

|

Slit length |

6 mm |

18 mm |

12 mm |

18 mm |

|

Slit width |

0.1 mm |

0.5 mm |

|

Linear speed [*1] |

5 m / min to 2000 m / min |

1 m / min to 1500 m / min |

|

Recorder output |

± 0.2 V / 0.1 mm |

± 1 V / 0.1 mm |

± 0.5 V / 0.1 mm |

± 1 V / 0.1 mm |

|

Alarm output |

Uneven red LED lit, Relay contact output (AC 250 V 2A resistive load) |

|

Alarm time [*2] |

0.1 seconds |

0.5 seconds |

0.1 seconds |

0.5 seconds |

|

Operating temperature |

-5 to 50 ° C (without condensation) |

|

Power supply [*3] |

DC ± 15 V |

AC 100V

50/60 Hz |

DC ± 15 V |

AC 100V

50/60 Hz |

|

Power consumption |

6VA |

10VA |

6VA |

10VA |

|

Outline Dimensions (mm) |

150 × 140 × 40 |

260 × 265 × 60 |

150 × 140 × 40 |

350 × 280 × 55 |

|

Weight |

0.8kg |

2.5kg |

1kg |

5kg |

[*1] PW-01 is a power supply dedicated to TM-1003W.PW-02 is a power supply for both TM-503W and TM-1003W.

(The enclosures are the same size for PW-01 and PW-02.)

[*2] Applicable line speed range changes depending on the hight of lump.

[*3] Alarm output can be hold by option

[*4] AC200V power supply specification is also available as an option.

|

Medium wire counterpart (Measurement object diameter: Φ 0.1 to 35 mm) |

|

Model No. |

TM-3001W |

TM-3002W |

TM-3004WA |

TM-3008W

(TM-3004WA)

(TM-3004WB) |

TM-3016W

(TM-3004WA)

(TM-3004WB)

(TM-3004WC)

(TM-3004WD) |

|

CAD file |

|

|

|

|

|

|

|

|

|

|

|

Direction of detection |

1 direction |

2 directions |

4 directions |

8 direction |

16 directions |

|

Measurement method |

Double slit infrared LED projection type |

|

Adaptive work outer diameter |

φ 0.1 - 35 mm |

|

Unevenness detection range |

0.05 to 10 mm |

|

Unevenness detection accuracy |

Maximum setting within ± 1% |

|

Slit length |

48 mm |

|

Slit width |

1 mm |

|

Linear speed [*1] |

1 m / min to 1500 m / min |

|

Recorder output |

± 0.1 V / 0.1 mm (for each axis) |

|

Alarm output |

Uneven red LED lit, Relay contact output (AC 250 V 2A resistive load) |

|

Alarm time [*2] |

0.5 seconds |

|

Operating temperature |

-5 to 50 ° C (without condensation) |

|

Power supply [*3] |

AC 100 V 50/60 Hz |

|

Power consumption |

5VA |

10VA |

10VA |

20VA |

40VA |

|

Outer dimension |

260 × 90 × 41 [mm] |

260 × 260 × 60 [mm] |

370 × 355 × 60 [mm] |

370 × 355 × 120 [mm] |

370 × 355 × 240 [mm] |

|

Weight |

1.5kg |

3kg |

6kg |

12kg |

24kg |

[*1] Applicable line speed range changes depending on the hight of lump.

[*2] Alarm output can be hold by option

[*3] AC200V power supply specification is also available as an option.

|

Bold wire counterpart (Measurement object diameter: Φ 0.1 to 60 mm) |

|

Model No. |

TM-4001 |

TM-4002 |

TM-4004A |

TM-4008

(TM-4004A)

(TM-4004B) |

TM-4016

(TM-4004A)

(TM-4004B)

(TM-4004C)

(TM-4004D) |

|

CAD file |

|

|

|

|

|

|

|

|

|

|

|

Direction of detection |

1 direction |

2 directions |

4 directions |

8 direction |

16 direction |

|

Measurement method |

Infrared LED projection type |

Double slit infrared LED projection type |

|

Adaptive work outer diameter |

φ 0.1 - 60 mm |

|

Unevenness detection range |

0.05 to 10 mm |

0.15 to 10 mm |

|

Unevenness detection accuracy |

Maximum setting within ± 1% |

Maximum setting within ± 2% |

|

Slit length |

70mm |

|

Slit width |

1.5mm |

|

Linear speed [*1] |

1 m / min to 1000 m / min |

|

Recorder output |

± 0.1 V / 0.1 mm (for each axis) |

|

Alarm output |

Alarm red LED on, Relay contact output (AC250V 2A resistive load) |

LED lighting (concave: yellow / convex: red), relay contact output (AC 250 V 2A resistive load unevenness output separately) |

|

Alarm time [*2] |

0.5 seconds |

|

Operating temperature |

-5 to 50 ° C (without condensation) |

|

Power supply [*3] |

AC 100 V 50/60 Hz |

|

Power consumption |

10VA |

20VA |

30VA |

60VA |

120VA |

|

Outer dimension |

450 * 120

× 50 [mm] |

640 * 560

× 160 [mm] |

807 * 674

× 136 [mm] |

807 * 674

× 272 [mm] |

807 × 680

× 424 [mm] |

|

Weight |

3kg |

25kg |

38kg |

76kg |

152kg |

[*1] Applicable line speed range changes depending on the hight of lump.

[*2] Alarm output can be hold by option

[*3] AC200V power supply specification is also available as an option.

|

Applicabe to extra thick wire (Measurement object diameter: Φ 1 mm to 80 mm, 1 to 130 mm) |

|

Model No. |

TM-6004A |

TM-6008

(TM-6004A)

(TM-6004B) |

TM-7003A |

TM-7009

(TM-7003A)

(TM-7003B)

(TM-7003C) |

|

CAD file |

|

|

|

|

|

|

|

|

|

Direction of detection |

4 directions |

8 direction |

3 directions |

9 direction |

|

Measurement method |

Single slit white tungsten lamp floodlight type |

|

Adaptive work outer diameter |

φ 1 to 80 mm |

φ1 to 130 mm |

|

Unevenness detection range |

0.2 to 10 mm |

|

Unevenness detection accuracy |

Maximum setting value within ± 2% |

|

Slit length |

95 mm |

135 mm |

|

Slit width |

1.5 mm |

|

Linear speed [*1] |

0.3 m / min to 500 m / min |

|

Recorder output |

± 0.1 V / 0.1 mm (for each axis) |

|

Alarm output |

LED lighting (concave: yellow / convex: red), relay contact output (AC 250 V 2A resistive load unevenness output separately) |

|

Alarm time [*2] |

0.5 seconds |

|

Operating temperature |

-5 to 50 ° C (without condensation) |

|

Power supply [*3] |

AC 100 V 50/60 Hz |

|

Power consumption |

30VA |

60VA |

30VA |

90VA |

|

概略外寸 |

720 x 660

× 153 [mm] |

720 × 660

× 306 [mm] |

990 × 930

× 125 [mm] |

990 × 930

× 375 [mm] |

|

Weight |

38kg |

76kg |

60kg |

180kg |

[*1] Applicable line speed range changes depending on the hight of lump.

[*2] Alarm output can be hold by option

[*3] AC200V power supply specification is also available as an option.

In addition to this, you can also prepare products such as TM-6020 (20 axis) and other multi-axis products.

|

Gauge Fixture / Calibration gauge unit for Surface Variation Detector

|

Calibration gauge unit

|

Gauge outer diameter (mm) |

Model |

Accuracy |

|

Φ1.0 |

TMG-10 |

±1μm |

|

Φ0.5 |

TMG-05 |

±1μm |

Note) It can be available down to Φ0.1.

Gauge Fixture and corresponding gauge unit table

|

Target Model |

Calibration gauge to use |

Mounting jig type |

|

TM-1000S |

TMG-05 |

01 |

|

TM-1003 |

TMG-05 |

02 |

|

TM-1000XY |

TMG-05 |

03 |

|

TM-1004 |

TMG-05 |

04 |

|

TM-1100XY |

TMG-05 |

05B |

|

TM-1003W |

TMG-05 |

06B |

|

TM-1104W/TMS-1104W |

TMG-05 |

07B |

|

TM-503W |

TMG-01 |

16B |

|

TM-3001W |

TMG-10 |

08B |

|

TM-3002W |

TMG-10 |

09 |

|

TM-3004W |

TMG-10 |

10B |

|

TM-3008W |

TMG-10 |

10B |

|

TM-3016W |

TMG-10 |

10B |

|

TM-4001/4001W |

TMG-10 |

---- |

|

TM-4002 |

TMG-10 |

12B |

|

TM-4002W |

TMG-10 |

17B |

|

TM-4004 |

TMG-10 |

13B |

|

TM-4008 |

TMG-10 |

13B |

|

TM-4016 |

TMG-10 |

13B |

|

TM-6004 |

TMG-10 |

14B |

|

TM-6008 |

TMG-10 |

14B |

|

TM-6016 |

TMG-10 |

14B |

|

TM-7003 |

TMG-10 |

15B |

|

TM-7009 |

TMG-10 |

15B |

|

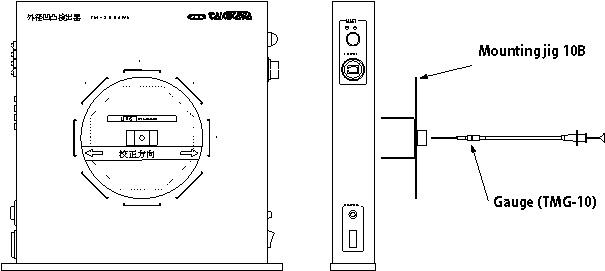

Example of calibration method (TM-3004W)

|

|

|

|

|

Although our detectors are calibrated at the time of shipment, when it is necessary to perform calibration for checking the sensitivity at the time of inspection etc., please perform calibration according to the following method with the calibration gauge unit. The calibration gauge unit to be used is "TMG - 10, Gauge Fixture 10B".

** Before calibration, please be sure to clean the glass filter of the projecting / receiving part and warm up for 10 minutes.

I will explain with 1 axis as an example.

-

Set the Gauge Fixture according to the axis for calibration (this time, 1 axis). (The figure below)

-

Set the level setting dial to "1.00".

-

Insert the gauge tip quickly into the center of the measuring range. At this time, please insert gauge so as not to be inclined as much as possible.

-

When the gauge tip is inserted while repeating the insertion several times, adjust the gain setting VR of 1 axis the lowest to light up the detection alarm lamp.(herein after lamp)

* It is not abnormal although the lamp may light up when extracting the tip of the gauge.

* Set an interval of about 3 seconds after the lamp is turned off when repeating the insertion of the gauge tip.

* VR for gain setting increases sensitivity when turned clockwise, and decreases when turning it counterclockwise.

-

Change the level setting dial to "1.03".

-

Repeat the insertion of the gauge tip in the same way.Now adjust the VR for 1 axis gain adjustment so that the lamp does not light up when inserting the tip of the gauge.

-

The calibration will be completed after repeating steps (2) - (6) several times to light up at "1.00" and not light up at "1.03".

|

For Thin Wire

|

|

|

|

|

|

|

Outer dimension[W * H * D] 150×140×40(mm)

TM-503W |

|

Outer dimension[W * H * D] 260×265×60(mm)

TM-1100XY |

|

Outer dimension[W * H * D] 150×140×40(mm)

TM-1003W |

|

|

|

|

|

|

|

|

|

|

|

|

Outer dimension[W * H * D] 350×280×55(mm)

TM-1104W |

|

|

|

|

|

|

|

For Medium Wire

|

|

|

|

|

|

|

Outer dimension[W * H * D] 260×90×41(mm)

TM-3001W |

|

Outer dimension[W * H * D] 260×260×60(mm)

TM-3002W |

|

Outer dimension[W * H * D] 370×335×60(mm)

TM-3004WA |

|

|

|

|

|

|

|

|

|

|

|

|

|

TM-3008W |

|

TM-3016W |

|

|

|

|

|

For Thick Wire

|

|

|

|

|

|

|

Outer dimension[W * H * D] 540×160×100(mm)

TM-4001 |

|

Outer dimension[W * H * D] 630×560×160(mm)

TM-4002 |

|

Outer dimension[W * H * D] 807×674×136(mm)

TM-4004 |

|

|

|

|

|

|

|

|

|

|

|

|

|

TM-4008 |

|

TM-4016 |

|

|

|

|

|

|

|

Applicabe to extra thick wire

|

|

|

|

|

|

|

Outer dimension[W * H * D] 720×660×153(mm)

TM-6004A |

|

TM-6008 |

|

TM-7003A |

|

|

|

|

|

|

|

|

|

|

|

|

|

TM-7009 |

|

|

|

|

|

|

|

|

|