|

|

|

|

|

|

|

|

|

Counting event printer AD series

|

|

It receives alarm signals from various devices such as outer diameter measuring instruments and unevenness detectors, and continuously prints the wire distance and message at the time of reception.

Preset values (forecast/full) can be set for measured values, and alarms can be output via the RS-232C I/F (standard equipment).

In addition, it is possible to scale the measurement pulse, and by setting the correction distance for each message, the accurate measurement value can be recorded.

Equipped with a USB port, data can be saved and event names can be changed from a USB memory.

|

|

|

|

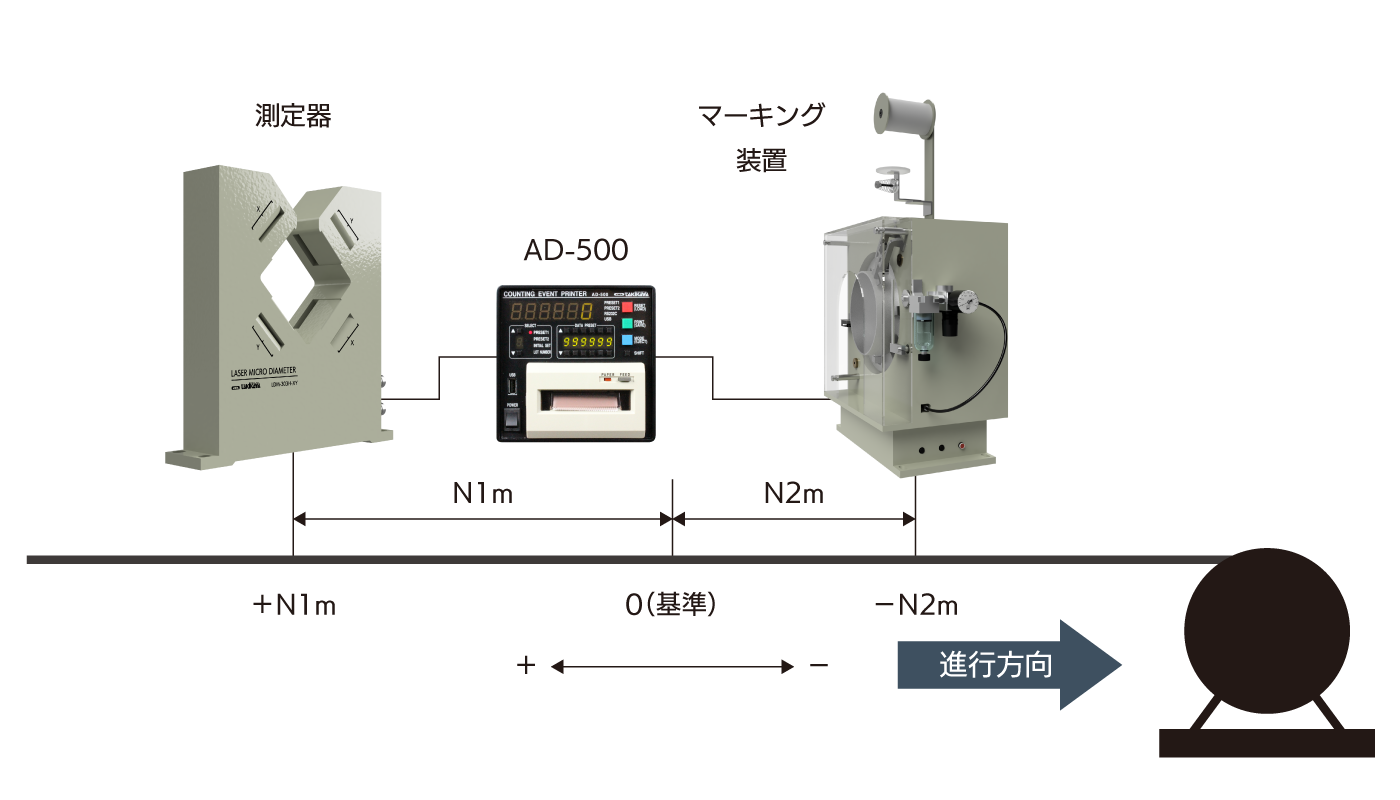

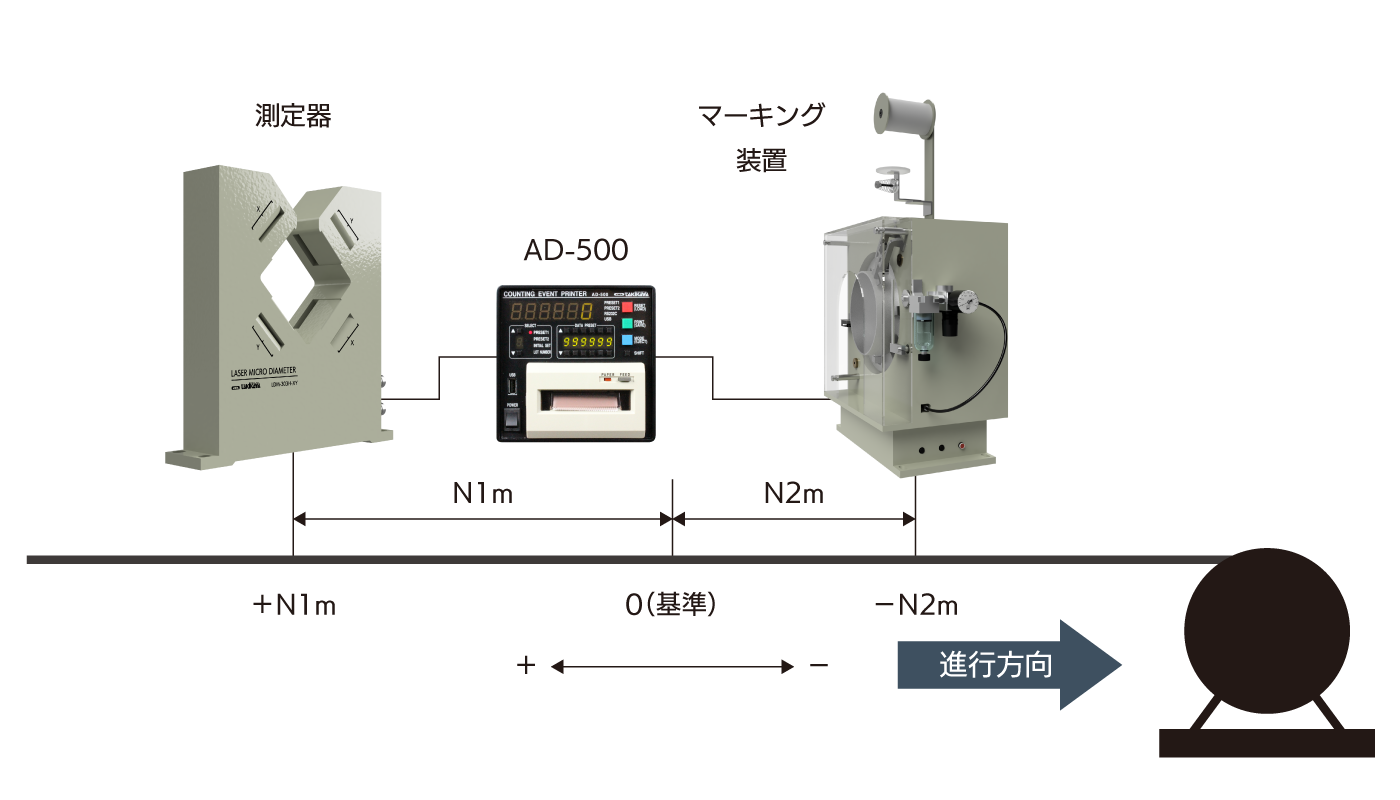

Event input distance correction setting mode

|

|

|

By presetting the position of the measuring instrument that will be the event input source from the reference position, the distance of the measuring instrument or marking device can be corrected.

As a result, it is possible to mark the exact position as well as print the exact measured value at the time of event occurrence.

|

|

|

|

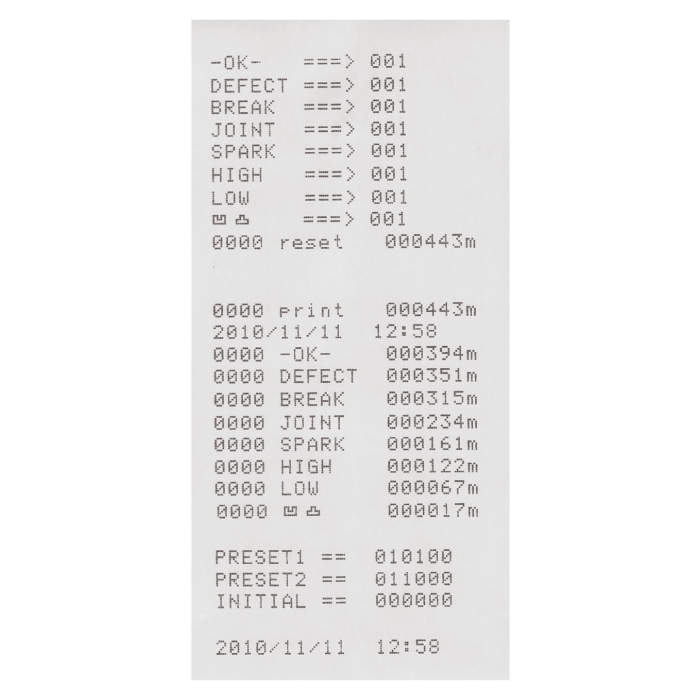

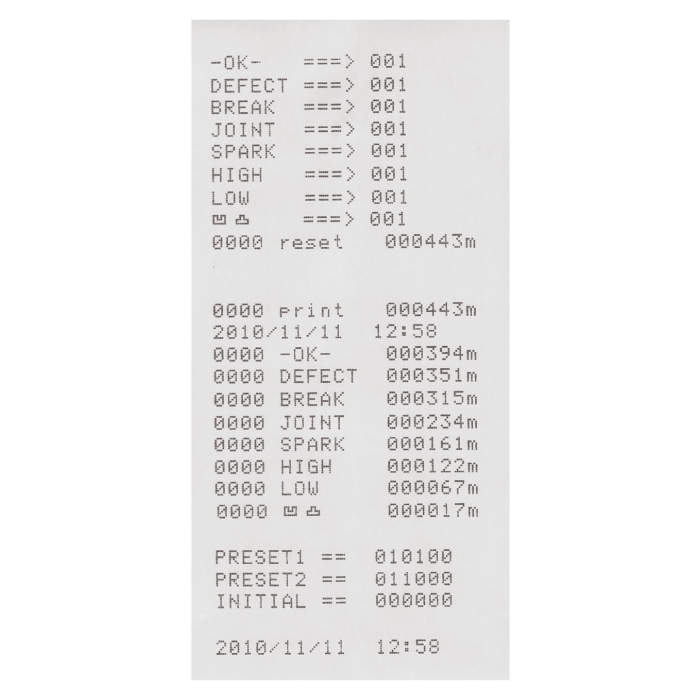

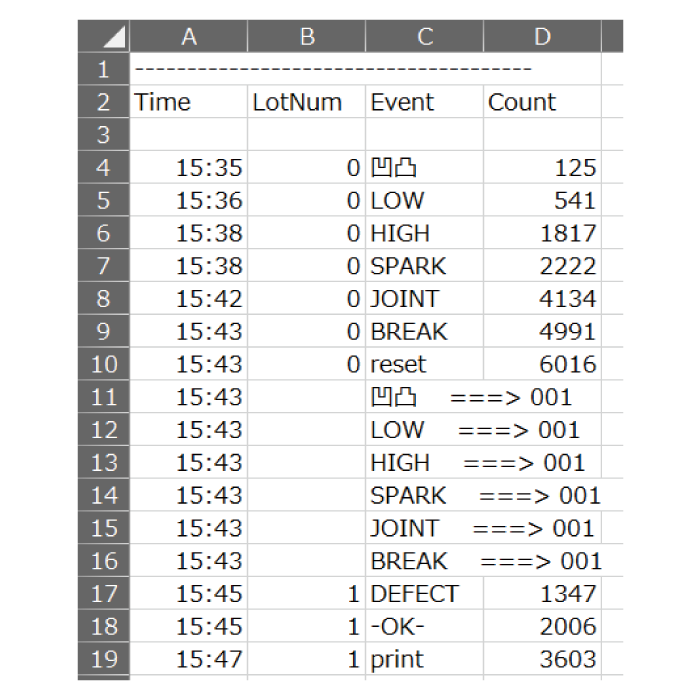

Data output example

|

|

You can enter up to 10 types of messages, including date, time and lot number.

Various settings including the clock can be saved for a long time by battery backup.

|

|

|

|

|

|

|

|

thermal paper

|

|

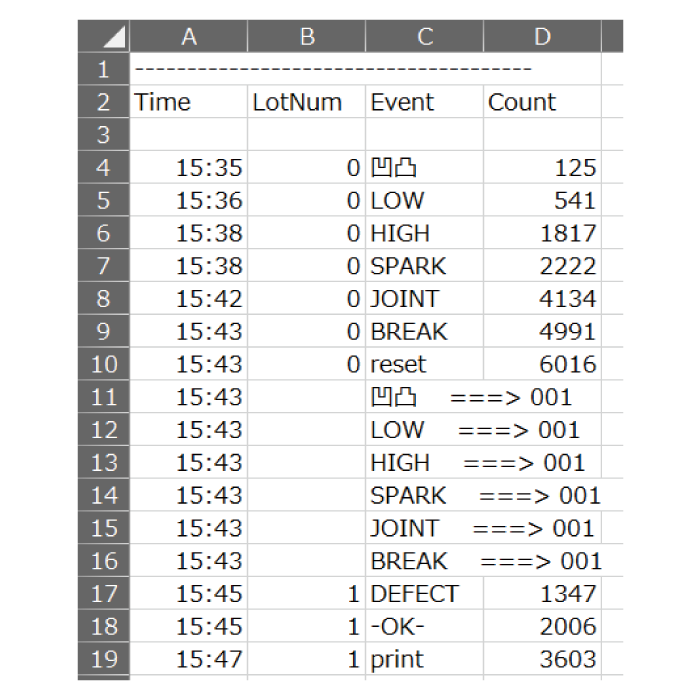

TXT format

|

|

CSV format

|

|

|

|

|

Specification

|

|

model name |

AD-500 |

|

CAD file |

|

|

|

Measuring function |

scale display |

6-digit green/red 2-color 7-segment LED |

|

Input clock for scale |

Supports single-phase pulse/A-phase B-phase pulse, up/down count possible |

|

clock pulse rate |

Maximum 2kPPS/100PPS selectable |

|

pulse rate |

Can be set arbitrarily within the range of 0.00001 to 999999m/pulse |

|

Scale sensor power supply |

DC+12V Max.70mA |

|

event input |

Number of event messages |

10 types |

|

Message event input |

Rear terminal block |

|

Reset event input |

Front panel switch, rear terminal block, RS-232C |

|

print event input |

Front panel switch, rear terminal block, RS-232C |

|

Rename message event |

Changeable via RS-232C/USB memory |

|

various settings |

Various parameter settings |

Digital setting by 6-digit green 7-segment LED |

|

PRESET1 (full) |

6 digits (absolute value setting) |

|

PRESET2 (Forecast) |

6 digits (absolute value setting or relative value setting to PRESET1 is also possible) |

|

Each PRESET output |

Measured value 7-segment red display, front panel LED, relay contact, RS-232C |

|

initial set |

6 digits |

|

lot number |

4 digits can be automatically updated |

|

Event input distance correction |

More accurate measurement is possible by setting the correction distance for each message event |

|

printing |

printer |

58mm width, 20 digits, thermal method |

|

No recording paper output |

Front panel LED, relay contact, RS-232C |

|

USB |

memory controller |

USB 2.0 host controller |

|

function |

Event data save function to USB memory, set value load/save function |

|

Marker output |

Relay contact output, pulse width can be set in units of 1 msec in the range of 0 to 60000 msec |

|

clock function |

year-month-day-hour-hour |

|

battery backup |

Backup scale, clock, and various settings (backup time: 1 month or more) |

|

external communication |

RS-232C standard equipment (baud rate 9600/19200bps) |

|

power supply |

AC90-240V free power supply 50/60Hz |

|

power consumption |

8 VA or less |

|

|

|

|

Communication unit AD-COM

|

|

|

It is used by connecting with our company's laser outer diameter measuring instrument and counting event printer.

By inputting the line speed control voltage, the date/time/measurement value/outer diameter value/line speed/event name at the time of event occurrence are recorded, and the date/time/measurement value/outer diameter value/line speed is recorded every 5 seconds. record.

Recorded data is saved in CSV format on a LAN-connected computer.

|

|

|

|

|

|

|

Product & Technology News

LDM Series

Download Catalogue

|