|

|

Pump Drive F600

Simple, reliable flow controlApplications involving the flow of water demand extreme reliability and low energy consumption. Control Techniques’ F600 drive, part of the newly introduced Specialist series of industry-specific drive technologies, builds on our company’s five decades of drives expertise, delivering precise, dependable flow control. Everything you need is baked into the drive itself. The F600 packs all of the features you’ll need, presented using terminology you’ll understand. This isn’t a generic drive with pump features tacked on; it’s a dedicated, specialist pump drive, designed from the ground up to deliver the reliability and efficiency you need. |

The perfect mix of application-specific features developed into a single solution |

|

|

Unmatched total cost of ownershipWith innovative protective features and extended equipment lifeThe F600 has comprehensive pump and motor protection features which minimise unplanned downtime, improving overall effectiveness and guaranteeing better value for money. Bring true resilience to your application and easily ride-through component failures. Automatic Error RecoveryIn the unlikely event of detecting an error with your pump, the F600 has the ability to dynamically recover and resume normal operation. Limit ProtectionIf the feedback exceeds the limits defined for your application, the F600 has the ability to raise an alarm or stop the drive to protect your equipment and preserve its lifetime. Transducer Loss ProtectionIn the event of losing connection to the transducer, the F600 can stop, continue to run at a fixed speed or ignore the fault depending on the application requirements. Fire modeFire mode allows the drive to disable all trips and to continue to run uninterrupted during emergency events if the application requires.

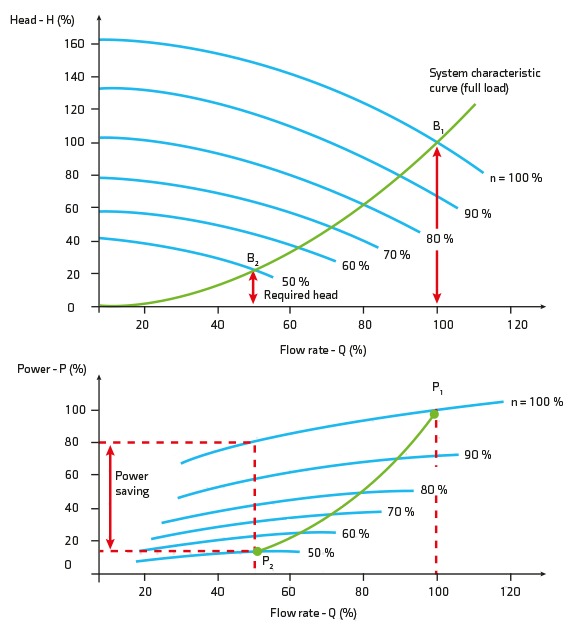

Save on energy through a wide range of energy featuresThe F600 is 98% efficient, meaning very little energy is lost in power conversion.Even more, the real savings potential gets unlocked by the F600’s built-in features that can further reduce energy consumption: Low load savingsThe F600 helps maximise energy savings when demand is low. Activing Control Techniques’ leading-edge Low Load Power Saving function, the drive dynamically reduces the voltage applied to reduce losses in the motor and make the system more efficient.

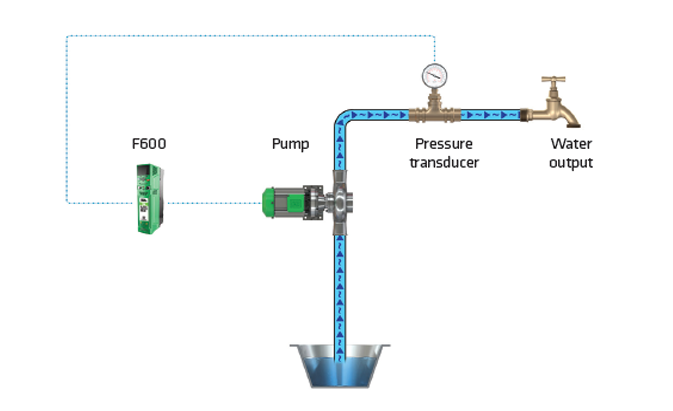

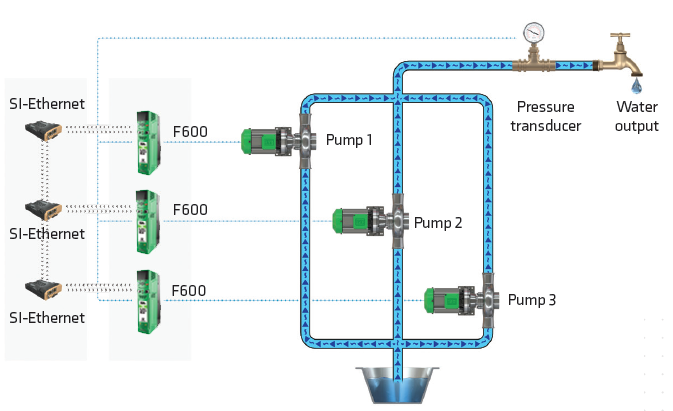

Sleep modeWhen demand falls below a specified set-point the drive will automatically enter sleep mode and restart itself once demand rises above the set-point. Not only does this greatly reduce the amount of energy consumed, it also saves on equipment wear to preserve its lifetime. The F600 features optimised control for your flow applicationsPipe fillPrevent spikes in pressure at start-up using a controlled ramp, to protect your piping system and the pump itself. Dry-run preventionPrevent the pump running dry by checking the load against a threshold; with flexible configurations to dynamically adjust output, set an alarm or stop the drive. Over-cycling protectionOptimise drive, motor and pump sizing, and regulate pump wear by limiting the number of start-stops per hour. Flexible configurations allow to dynamically alter cycling reference limits, set an alarm or stop the drive when a limit is reached. No-flow detectionWhere there is no-flow or low-flow, the F600 drive can automatically enter sleep mode to save energy, based on the feedback of a pulsed flow transducer, or triggered by a flow switch, or detected by the software alone. CleaningLive, continuous monitoring of the system is used to trigger an automatic drive-based cleansing cycle to clear the pump impeller and help avoid maintenance costs on cleaning pump blockages. Level switch controlLevel switches provide critical protection for tanks in the event of the level reaching a “high” switch, whereby the pump is stopped, or a “low” switch, whereby the pump is started, to ensure pumping within tank levels. Pump Control Modes | Flexible support for every systemSingle pumpControl Techniques’ Single Pump mode is an effective and versatile variable speed control solution for maintaining a constant set-point in a single pump configuration.

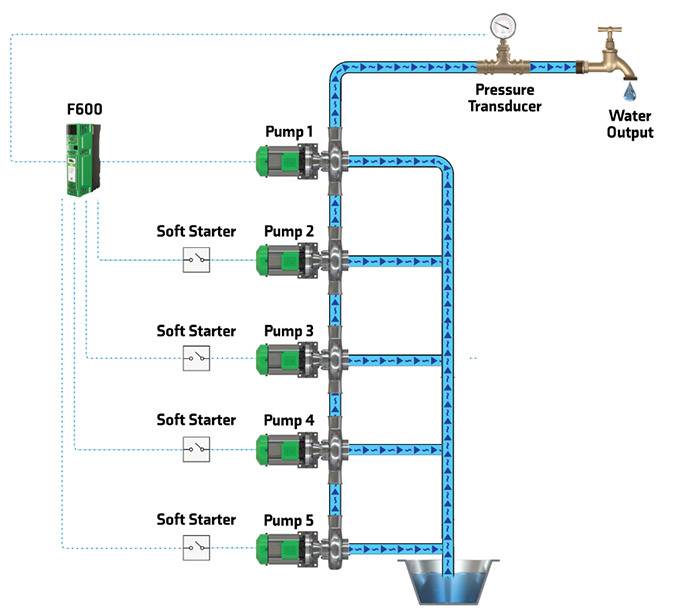

CascadeCascade mode allows the F600 to operate with up to 2 assist pumps to aid the primary pump when required.

Multi-leaderComplete control of your application with up to 3 x F600 drives and maximum energy savings with these variable frequency drives running parallel.

|

Ready to use pre-engineered high power drives

Ready to use pre-engineered high power drives

No cabinet required

No cabinet required