Academic institutes, universities |

A particular interest of Micro-Epsilon is the promotion of research in academic institutes and universities. High precision measuring devices are required for research in these institutions; new techniques for sensors or new measuring principles often also emerge in this context. New possible applications often emerge from interesting projects. |

Experimental tests on a drop impact tester In the automotive industry manufacturers go to great lengths to improve the passive safety of all vehicles in a collision. The so-called crash absorbers join the fenders with the longitudinal bearers and taken overall they can absorb energy through fixed bumpers and plastic deformation. In addition, attempts are made to reduce the vehicle weight through new designs and the use of new materials. The effect of the actual accident event can be replicated on special drop impact testers. Through the variation of the dropped weight and the height, the impact speed can reach 12.5 m/s (45 km/h). Apart from the force, the deformation is recorded during the collision with a fast triangulation sensor. Sensor technology applied |

| __________________________________________________________________________________________________________ |

Water depth measurement on a river model With investigations using realiztic models of flowing waters, the river bed must be sampled as accurately as possible and without physical contact. To do this, the laser-based optical displacement measurement system, optoNCDT, is used which features high accuracy with a large measuring range and is largely independent of the ground conditions. It is mounted together with the signal conditioning electronic unit on a measurement carriage movable in the X direction which is suspended from a traversing beam movable in the Y direction. The distance to the water surface is acquired simultaneously with a parallel-mounted ultrasonic displacement system. Sensor technology applied |

| __________________________________________________________________________________________________________ |

Deformation measurement on lightweight structures Specially designed measurement systems, which record the surface contours without reactive effects on the lightweight structures, are employed for the examination of component deformations under load. To achieve this, two laser-based optical displacement measurement systems can be mounted on a movable subframe subdivided with nineteen fixed reference points. Sensor technology applied |

| __________________________________________________________________________________________________________ |

Measurement of the radial deviation on superconducting magnets At the Institute for Solids and Materials Research (IWF) Dresden a motor with magnetic bearings has been developed using high temperature superconductors which can be employed for feed pumps for liquid nitrogen. The most important application of superconducting permanent magnets is the superconducting magnetic bearing. For the measurement of the radial deviation of these magnetic bearings, U1 eddy current sensors with special temperature compensation for -196 °C and 20 °C are used in the evacuated and cooled ambient. Sensor technology applied |

| __________________________________________________________________________________________________________ |

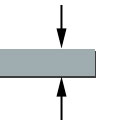

Thickness measurement using displacement sensors Thickness measurement using displacement sensors is a wide application area. Basically there are distinctions between non-destructive/destructive, non-contact/with contact and one-side/two-sided thickness measurement. The Micro-Epsilon measuring techniques for thickness measurement are all emission-free whereby no emissions regulations of any kind have to be complied with. Thickness measurements must be performed both with contacting as well as with non-contact sensors whereby non-contact measuring techniques show advantages as regards accuracy and measuring speed. There is also a distinction between one-sided and two-sided thickness measurement. Two-sided thickness measurements are carried out with at least one pair of sensors which are installed together on one axis. This pair of sensors measures the target synchronously. The difference between the measurement results (C-A-B) produces the thickness of the measuring object. One-sided thickness measurements must only be performed with non-contact sensors. In doing so, the target is only measured with one sensor and either only a part of the target thickness (e.g. layer thickness) or the complete measuring object thickness is measured. Thickness measurements are mainly used in process control and quality assurance, e.g. for the control of extrusion systems or 100% checking of tube diameters. Sensor technology applied |

| __________________________________________________________________________________________________________ |

3D profile measurement of soil samples German automation company Visutronik GmbH from Neubrandenburg, Germany has developed a laser scanningdevice to measure surface soil samples for subsequent geometric analysis: roughness, surface type expansion (e.g. earthworm courses), etc. The core of the measuring device is the scanCONTROL 2700-100 laser scanner. Sensor technology applied |

| __________________________________________________________________________________________________________ |

Closed-loop gap control in magnetic bearings Sensor technology applied |

| __________________________________________________________________________________________________________ |

High precision measurement of special profile sections in the production line In the factory research department a fully automatic system for optical geometry measurement has been developed, constructed and integrated into a production line for lift profile rail sections. The system acquires the deviation of±0.2mmfrom straightness in both axes, the length of the section and the thickness of the rail web to ± 0.02 mm in two tracks. Sensor technology applied |

| __________________________________________________________________________________________________________ |

Eddy current sensors in tribology testers Eddy current sensors from Micro-Epsilon are used for various measurement tasks in tribology testers of the ITR in Clausthal. They withstand the harshest ambient conditions there as they measure directly on the shaft in the tester. A tester with water lubrication and a tester which examines plain bearings for the automotive industry have already been realized. The position of the test bearing case and the relative movement between the rotor and the test bearing is detected in the tester using eddy current sensors. Sensor technology applied |

| __________________________________________________________________________________________________________ |

Active damping of liquid-cooled centrifuges At certain configurations of speed, filling level and design parameters, liquid-filled industrial centrifuges tend to produce unstable running characteristics which can lead to failure of the centrifuge. The instability, which arises due to interaction between the fluid and the centrifuge, cannot be rectified by passive means (dampers), so therefore the instability is corrected actively with the aid of a magnetic bearing and suitable closed-loop controllers. The deflection of the rotor, which is acquired with two eddy-current sensors orientated at 90° to one another, is used as input information for the controller. Sensor technology applied |