Profile, Contour, Surface The surface or the surface profile is frequently a decisive factor in quality inspection. Laser scanners from Micro-Epsilon are frequently used for this. If traversing laser point sensors are used, these also measure a profile of the surface. The profile measurement is often used on robots or inspection systems for controlling further processes. Sensor technology applied |

| __________________________________________________________________________________________________________ |

Coil edge Rolled sheets in the metal industry are wound on coils for transport. It is important that directly before and also after the coiling, to check the position and the edge condition of the metal strip. optoCONTROL optical micrometers are used for this. If the edge of the coil is within the measuring range during the winding or unwinding, the position and the edge structure can be determined from this. This technique ensures that the coil is wound correctly and also that the correct metal strip quality has been delivered for the unwinding. Sensor technology applied |

| __________________________________________________________________________________________________________ |

3D inspection and surface assessment of roof tiles The production of roof tiles places high demands on measurement and testing methods for ensuring constant high product quality. In the DASTOKON semi-automatic measurement and test system and in the BSPK pilot plant a laser triangulation sensor of the Series ILD 1800 is used for the 3D inspection and for surface assessment. Sensor technology applied |

| __________________________________________________________________________________________________________ |

Defect recognition on worktops Kitchen worktops are now made from a variety of materials, e.g. natural or artificial stone, solid wood and laminate (e.g. HPL). All these materials offer benefits and have special characteristics. However, a defect-free surface finish and perfect edges are critical production factors. The example above is a so-called laminate worktop with a stone decor. As the cutting edge of this top is rough and unclear, it is covered with sidebars. Foreign bodies, uneven distribution of the adhesive or unevenness when closing may produce open joints between the top material and the sidebars. The scanCONTROL 2910-25 laser profile scanner is used to inspect if any open joints are present. Sensor technology applied |

| __________________________________________________________________________________________________________ |

Measuring dental samples confocal Confocal optoNCDT 2401 sensors are used to check the surface topography of dental samples. These sensors are distinguished by their high resolution and independence from the type of material surface involved. The desired area on the object being measured is marked by software. The system is used on surfaces such as plastic, paper, nonwoven fabric, glass or metal. Sensor technology applied |

| __________________________________________________________________________________________________________ |

On-line inspection of sealing compound in covering lid After injection of the sealing compound in the covering lid, curing takes place in the tunnel furnace. Here, fault points and faulty thicknesses of compound must be acquired and faulty lids must be sorted out in the production process. A laser-based optical displacement measurement system samples the compound surface of the rotating lid for a quality inspection. The monitoring of the thickness contour within the permissible tolerance limits and the sorting of the faulty lids occurs with the aid of the PLC that is employed. Sensor technology applied |

| __________________________________________________________________________________________________________ |

Inspection of rotationally symmetrical parts The scanCONTROL laser scanner is used for part inspection of various hypoid-tooth components and a digital model of the tooth structure of the component is generated by the measurement system. In this way, the 3D point cloud can be evaluated afterwards according to customer requirements. Previously, this type of inspection was done with manual removal of the part. Sensor technology applied |

| __________________________________________________________________________________________________________ |

Digital 3D measurement of complex parts and shapes Mabotic devepols and manufactures various designs of digital scanning units. scanCONTROL laser scanner are often used for digitization of parts. The scanner projects a laser line onto the object being measured and records the profile of the line. When the scanner is mounted on a linear axis and the scanner traverses over the measurement target, a 3D image of the target can be generated. Sensor technology applied |

| __________________________________________________________________________________________________________ |

Display glass defects A special measuring system has been developed for the quality control of display glass. The glass pane is placed on a measuring table by a robot. A measuring arm with several confocal sensors traverses the glass pane there. If any defects are found, the pane is marked as NOK and rejected. The scanCONTROL laser scanner simultaneously circumnavigates the edges and checks these for defects and dimensions. After the check has been completed successfully, the pane is lifted back into the production process and the next measurement is started. Sensor technology applied |

| __________________________________________________________________________________________________________ |

Reading the DOT code on tires When manufacturing automobiles for the American market, the DOT numbers of the tires must be stored. Vision systems are not suitable for reading the code, due to the poor contrast involved (black letters on a black background). The scanCONTROL 2750-100 measures the distance from the surface with the aid of triangulation. The sensor transmits a height profile of the tire wall directly to the software application. Sensor technology applied |

| __________________________________________________________________________________________________________ |

ROV (Remotely Operated Vehicle) for pipeline inspection To meet safety regulations, the inspection of the internal parts of pipelines is mandatory, as any defects can lead to cracks, which could result in complete pipe failure or, in the worst case, in personal injury. The critical factor is the weld seam. DEKRA developed a fully automatic vehicle that solves this task by using a combination of visual inspection and geometrical measurements performed by a scanCONTROL laser scanner from Micro-Epsilon. |

| __________________________________________________________________________________________________________ |

Flat glass defects A special measuring system has been developed for the quality control of flat glass. The glass pane is placed on a measuring table by a robot. A measuring arm with several confocal sensors traverses the glass pane there. If any defects are found, the pane is marked as NOK and rejected. The scanCONTROL laser scanner simultaneously circumnavigates the edges and checks these for defects and dimensions. After the check has been completed successfully, the pane is lifted back into the production process and the next measurement is started. Sensor technology applied |

| __________________________________________________________________________________________________________ |

Water depth measurement on a river model With investigations using realiztic models of flowing waters, the river bed must be sampled as accurately as possible and without physical contact. To do this, the laser-based optical displacement measurement system, optoNCDT, is used which features high accuracy with a large measuring range and is largely independent of the ground conditions. It is mounted together with the signal conditioning electronic unit on a measurement carriage movable in the X direction which is suspended from a traversing beam movable in the Y direction. The distance to the water surface is acquired simultaneously with a parallel-mounted ultrasonic displacement system. Sensor technology applied |

| __________________________________________________________________________________________________________ |

Shape measurement of rotation symmetrical parts As rotary pistons for pumps must have very precise surface geometries, the pistons have to undergo 3D shape measurement. The scanCONTROL laser scanner is moved vertically by a linear axis in a special measuring machine. In doing so, the piston rotates in the measuring range of the scanner. A resolution of 3µm is achieved using this. Sensor technology applied |

| __________________________________________________________________________________________________________ |

Automatic winding of glass fiber cables An even and tight winding must be maintained for the automatic winding of glass fiber cables on drums. scanCONTROL 2800 profile scanners are used for monitoring the coiling machine. They monitor the windings on the drum and control the movement components of the machine using the results. Sensor technology applied |

| __________________________________________________________________________________________________________ |

Rail wear Tram or train rails are subject to constant wear either due to corrosion or due to friction during use. Rails are checked for wear completely automatically using a system developed by Micro-Epsilon. A test car records the surface profile of the rail during the journey. The data obtained is compared with standard values and if a section is recognized as worn down, the system stores the track section for later maintenance. The profiles are measured using several line scanners of the type scanCONTROL 2800. Sensor technology applied |

| __________________________________________________________________________________________________________ |

Position of the rubber grip on golf clubs It is important for the production of golf clubs that the rubber grip is perfectly positioned on the shaft. The rubber grip must not only be completely on the shaft; the rubber must also not be twisted. The scanCONTROL 2800 is used for this measurement in the production environment. Sensor technology applied |

| __________________________________________________________________________________________________________ |

Measurement of large geometries with precision machines Measuring complex part geometries is a task for the scanCONTROL laser scanner. Laser scanners are used in the precision machines of EHR in order to perform a component inspection at high resolution and without contact. The special feature is that using a scanner, not only is an inspection possible from the outside but also from the inside. Sensor technology applied |

| __________________________________________________________________________________________________________ |

Optical sensors in side trimming systems of saw mills The tree trunk cut into planks in saw mills still shows the wane of the original tree on the edges. In order to achieve an optimum cutting width and thus a maximum yield here, laser triangulation sensors are installed every 30 to 50 cm which measure the transverse section of the plank in the flow path. The maximum width of the plank is calculated using special software. Sensor technology applied |

| __________________________________________________________________________________________________________ |

Inline burr measurement on sheet edges in body manufacture In order to avoid corrosion, continuous and error-free corrosion protection is a critical factor in the painting process. As the thickness of the applied painting on burrs can only be determined under challenging limitations, it is a decisive advantage that the burrs are recognized early in the production process before the corrosion protection and other paint layers are applied. In contrast to fixed solutions that enable a random test, Micro-Epsilon offers its scanCONTROL 2910-10/BL Plug & Play system which provides the required precision with its high point resolution of approx. 8µm along the laser line in order to recognize burrs reliably even during inline measurements. Sensor technology applied |

| __________________________________________________________________________________________________________ |

Adhesive beading check on border strip Border strips are automatically adhered to glass by robots in vehicle production. This automatic process must be monitored as the application of uniform adhesive beading by the robot is not certain. The adhesive beading is checked immediately after the application by the same robot using a scanCONTROL 2810 for height, width and position. |

| __________________________________________________________________________________________________________ |

Robot positioning for application of seals In order to permanently protect weld seams against the penetration of moisture, BMW AG’s Leipzig factory seals the weld seam on the roof rail. A robot automatically applies sealant at the position where the side frame is joined to the roof panel. A laser sensor from Micro-Epsilon, which prepositions the robot using distance measurement, is used so that the robot knows exactly where each weld seam is located. Sensor technology applied |

| __________________________________________________________________________________________________________ |

Adhesive beading check It is important during the gluing in of glass panes in automobile production that the adhesive beading shows a constant track. Therefore a robot arm tracks the adhesive beading track exactly with a scanCONTROL laser scanner. In doing so, the robot centers itself on the adhesive beading automatically due to the measured data. In doing so, the scanner measures the surface profile of the adhesive beading. The supplied software automatically detects whether the beading is too narrow, too wide or too flat. Sensor technology applied |

| __________________________________________________________________________________________________________ |

Measurement of contact lenses The object must endure various tests during the search for new materials for contact lenses. In doing so, the lens is located in a small case with saline solution. The lenses are inspected in the case without contact using the optoCONTROL 2600 for dimension changes during heating and expansion of the lenses. The particular benefit is that the measurement functions through the glass case and through the salt solution. Sensor technology applied |

| __________________________________________________________________________________________________________ |

Coplanarity of connector pins Using connectors and sockets, electrical circuits can be alternately opened and closed. The connector pins must be correctly oriented in order to prevent the pins from bending during connection. As this cannot always be guaranteed by the mounting process, it is important to inspect the coplanarity and the orientation of the connector pins to one another. In many cases, mechanical sensing devices carry out this task. However, this procedure has its disadvantages. First, the sensing device itself applies a certain force onto the pins, and second, the mechanical parts are subject to wear, which reduces the measurement accuracy and reliability. Non-contact scanCONTROL profile sensors measure are wear-free and are applied in a variety of pin inspection tasks. Sensor technology applied |

| __________________________________________________________________________________________________________ |

Paintwork defects The exterior appearance is an important factor for many surfaces. The reflectCONTROL inspection system is suitable for automatic defect inspection of reflecting surfaces. This system measures the quality of the surface without contact using light reflections and classifies the defects found. The system is particularly suitable for painted surfaces or smooth plastic. Different versions make possible adequate usage for automobile body shells or smaller elements. Sensor technology applied |

| __________________________________________________________________________________________________________ |

Bearing shell surface Sliding bearings are used in combustion engines for the crankshaft and camshaft. The bearing shells are often composed of three layers whereby the inner layer is only metalized or sputtered. If there are residues on the bearing shell, the inner layer has too little purchase and flakes off. The system from Micro-Epsilon checks all bearing shells at the end of the production for a faultless condition of the surface. A BV camera records an image of each shell which is evaluated afterwards completely automatically. If necessary, the system also takes over the selection afterwards depending on the measurement result. Sensor technology applied |

| __________________________________________________________________________________________________________ |

Dimensional Testing of Cans for the Food Industry Accurate dimensions and shape of the prefabricated cans and can-lids is of prime importance, in order to ensure that the lids and the cans match properly and form a permanent airtight seal after the filling and sterilization process. This in order to avoid costly batch sealing failures in the canning industry. A special non-contact automated measurement testing machine was developed to control the dimensional integrity of the cans and the matching lids. Sensor technology applied |

| __________________________________________________________________________________________________________ |

Image processing system for the detection of markings In order to increase the process reliability in the final assembly of cars it is necessary make a reliable differentiation between the wheel and spare wheel on different types of vehicle once the tire has been fitted to the rim. For this purpose line markings are applied to the sides of the tire. They must be reliably and fully automatically detected when all components (tire,rim, transport belt) are optically similar (matt black). |

| __________________________________________________________________________________________________________ |

2D/3D measurement station for gaskets Even if gaskets are just very small components in plant and machinery, they are still critical in terms of their function and operational reliability. However, mechanical engineering companies normally purchase these components rather than produce them in-house. Reliable quality control at goods inwards is therefore essential. Sensor technology applied |

| __________________________________________________________________________________________________________ |

Measuring the base height of filters in the automotive industry In automotive filter production, faultless workmanship is essential for the proper functioning of the filter. In addition, the specified height of the filter is also critical in order to prevent any damage occurring to the periphery of the filter during assembly. In cooperation with special purpose machine builder Limberger GmbH and the Signum image processing specialists, scanCONTROL laser profile scanners were integrated to a filter test machine. Sensor technology applied |

| __________________________________________________________________________________________________________ |

Paper fold recognition in printing machines Possible folds produced in the paper web that remain unnoticed can have far-reaching consequences during processing and often lead to unusable printed products. Extreme differences in printing registration, i.e. inaccuracies when correlating overlapping colors may also occur. Another risk is that the paper web tears while going through the print machine. Any machine stoppages or changeovers can significantly increase printing costs. Non-contact, optical measurement technology is a suitable solution. Sensor technology applied |

| __________________________________________________________________________________________________________ |

Stitching position of airbags As interior parts, the covers must therefore harmonise with the overall appearance. The high aesthetic requirements placed on the cockpit, seats, interior trim and steering wheel are particularly important for this functional component. While assembly gaps cannot be measured prior to installation, like many other elements of a car, the airbag stitching can be inspected during production by using a scanCONTROL 2910-25 laser profile scanner. The scanner detects the contour of the stitching while being guided by a robot arm and evaluates several features synchronously. Sensor technology applied |

| __________________________________________________________________________________________________________ |

Profile measurement of compressor blades under high temperature conditions The thermal geometric change under operating conditions needs to be measured on a new type of composite material for gas power plants. Sensor technology applied |

| __________________________________________________________________________________________________________ |

Profile measurement system In the field of quality assurance, e.g. in the tire industry, profile measurements of the tread and sidewall must be carried out. Sensors or complete profile measurement benches with precision laser and computer systems can be used for this which relay a fully automatic sequence through to the finished output of the required layout. Sensor technology applied |

| __________________________________________________________________________________________________________ |

Profile sensor for tire measurement on the test rig Tire properties are crucial for safety, driving response and comfort in modern automobiles. To ensure constant quality at the highest level 100% inspection of tires is already required in production. Apart from dynamic stress tests, the acquisition of bulges, constrictions and impacts is of primary importance. Sensor technology applied |

| __________________________________________________________________________________________________________ |

Automatic test station for heat exchangers Heat exchangers in plant and machinery serve as heat transfer mechanisms between different material flows. To maximise the heat-emitting area, they are designed using multiple plates. Respectively one connecting flange for the material-conveying cables is welded or soldered onto the last plate. The position and the flatness of the flanges have to fulfil highest requirements so that these can be connected at the desired point. Sensor technology applied |

| __________________________________________________________________________________________________________ |

Inspection of saw teeth Whether in a linear arrangement or a saw blade, saw teeth are used for cutting materials. Due to increasing demands for reproducible production results, saw teeth must fulfill the highest quality standards. The reproducible form of the saw teeth, which are often hardened, is therefore critical. The scanCONTROL 2960-100 laser profile scanner is tilted above the strip to continuously inspect the angle of the cut and the maximum points of the saw tooth edges. |

| __________________________________________________________________________________________________________ |

Fluid level measurement of aluminum pig irons A German manufacturer of prestressed concrete products uses a number of 3D measurement systems by InSystems Automation with optical sensors made by Micro-Epsilon for quality control of railway sleepers. The systems include a portal station that is fitted to a forming station above the conveyor technology. Two scanCONTROL LLT2800-100 laser profile sensors travel along the portal axes and scan the sleepers from above. Sensor technology applied |

| __________________________________________________________________________________________________________ |

Tester for (railway) wheel rim measurement Testers are integrated in the track bed for the wear control of wheel rims on trains. The profile is checked during the passage of the train. Point-type and line-type lasers measure the diameter and the profile of the wheel. Thus, a precise statement of when the wheel must be reprofiled is possible. The measuring technology thereby is exposed to all weather influences. Sensor technology applied |

| __________________________________________________________________________________________________________ |

Tire surface Three laser scanners from the scanCONTROL series measure the surface profile of tires. The turnkey tester is at the end of the production line where each tire is examined for dents and bulges. The tire is clamped and rotated by 360° within one second. Lettering and symbols are recognized by the software and not assessed as bulges. The process takes place completely automatically and makes a 100% check possible. The tire is reintroduced back into the production process after completion of the testing. Sensor technology applied |

| __________________________________________________________________________________________________________ |

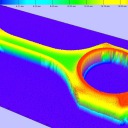

Completely automatic 3D repair welding For heavy equipment such as soft coal excavators, it is often cheaper to repair parts than to replace them. For the repair of chain links during maintenance work, the worn material is welded on again by a robot. In order to automate this process, a 3D surface scan must be performed in advance so that the necessary welding lines can be calculated. The Mabotic company uses laser scanners from Micro-Epsilon for this. Sensor technology applied |

| __________________________________________________________________________________________________________ |

3D profile measurement of soil samples German automation company Visutronik GmbH from Neubrandenburg, Germany has developed a laser scanningdevice to measure surface soil samples for subsequent geometric analysis: roughness, surface type expansion (e.g. earthworm courses), etc. The core of the measuring device is the scanCONTROL 2700-100 laser scanner. Sensor technology applied |

| __________________________________________________________________________________________________________ |

In-line inspection of the rubber on windshield wiper blades A faultless surface is indispensable for the functionality of wiper blades. Therefore, wiper blades are inspected by the measuring system after the extrusion in the endless state. In doing so, two scan CONTROL 2800 sensors are used. The inspection is performed above and below the material. Sensor technology applied |

| __________________________________________________________________________________________________________ |

Measurement of key profiles In the production of security keys, the correct blank must be located in the machine before grinding of the teeth can be checked. An optoNCDT 2200 laser sensor traverses across the profile, recording the surface profile precisely while doing so. A measurement profile without any gaps and a very small measuring spot size are important here. Sensor technology applied |

| __________________________________________________________________________________________________________ |

Weld seam profile Welding robots which perform the joining automatically are often used for joining metals. For visible parts, the weld seam must satisfy certain optical criteria; for example, there must be no remaining welding beads. A laser scanner is installed directly after the welding head for this. It measures all the weld seams made and arranges for the robot to make corrections if necessary. Sensor technology applied |

| __________________________________________________________________________________________________________ |

Weld seam tracking for pipeline inspection Defective weld seams are often the reason for leaks on pipelines. Therefore, the seams are inspected on the outside after the welding with the profile scanner scanCONTROL 2800. In doing so, the scanner is positioned in a testing device on the pipe. After the manual alignment, the scanner automatically inspects the weld seam and centers itself automatically on the pipe in doing so. Sensor technology applied |

| __________________________________________________________________________________________________________ |

Dimensional accuracy of sectional doors With sectional doors for parquet or laminate flooring, key and slot joints for individual sections are applied. However, these sections are opened and closed frequently. To enable a robust but permanent flexible key and slot joint, specified dimensions are critical and must be adhered to. This is particularly important in the case of significant temperature differences or inaccurate dimensions, where the door could be locked or positioned incorrectly. The measurement of the key and slot joint is therefore critical in ensuring the correct manufacturing dimensions. Sensor technology applied |

| __________________________________________________________________________________________________________ |

Monitoring embossment depth Embossed serial numbers enable worldwide unambiguous identification of, for example, car body shells. For increased safety measures (e.g. in case of theft), car body IDs are punched into the vehicle frame. Therefore, the depth of the embossment is a critical factor. This is why embossing machines operate using optoNCDT 1420 laser triangulation sensors from Micro-Epsilon. These determine the precise distance between the embossing tool and the component. Based on these distance values, the tool can be positioned correctly. After the embossment is finished, the sensor measures the profile of the embossment and ensures that all characters are embossed to the required depth. Sensor technology applied |

| __________________________________________________________________________________________________________ |

Welded sheets on gas valves For automatic welding processes, the quality of the weld is often dependent on how precisely the welding head is positioned for the seam place. If the positioning is checked by a measurement system before the welding, unnecessary rejection can be prevented right from the start. The elster company uses the scanCONTROL 2810 profile sensor for this. The position of the scanner to the valve is initially measured eight times before the welding process. The laser welding head is positioned to the seam based on these data. Sensor technology applied |

| __________________________________________________________________________________________________________ |

Measurement of pre-stressed steel An inspection system for incoming goods inspection has been developed for a manufacturer of pre-stressed concrete, which detects the profile depth of delivered batches and continuously records this information to a database. Sensor technology applied |

| __________________________________________________________________________________________________________ |

Non-contact roller measuring deviceIn the cement and mineral industry roller mills are used for fine grinding of the raw materials. During the milling process the rollers are subject to high wear, which strongly reduces the quality of milling at the edges of the rollers. With a laser-optical roller measuring device the necessary regrinding process can be initiated at the right time, and the success of such regrinding can be determined. A protective device with special damping elements and air nozzles protects the laser-optics sensor against vibrations, and keeps the optical system and the beam path free of dust. Sensor technology applied |

| __________________________________________________________________________________________________________ |

Windscreen defects During the production of windscreens, it can happen that the correct curvature of the windscreen has not been maintained or the fissures and cracks in the surface make the windscreen unusable. A system has been developed for this purpose which inspects the windscreens completely in-line for a surface free from defects. Several confocal sensors on a measuring beam measure the distance to the surface. Using the automatic centering function of the confocal sensors, they track the curvature of the surface precisely. The high resolution makes it possible to inspect the windscreen for cracks and fissures at the same time. |