Width The width of an object is often an important aspect for dimension control. The width can in some circumstances be interpreted as thickness and can therefore be resolved using thickness measurement. Different measuring principles come into consideration for the width measurement depending on the size of the object. For large objects such as strip material or packages, the measurement data from two sensors are usually calculated together. Optical methods such as Thru-Beam laser micrometers, laser sensors or eddy current and capacitive sensors are suitable for this. One sensor which measures the object width with one measurement is often sufficient for smaller objects such as individually packaged goods. scanCONTROL split beam sensors or vision4A image processing systems are suitable for this. Sensor technology applied |

| __________________________________________________________________________________________________________ |

Inspection of sockets There are many uses of sockets in the automotive area. The dimensionCONTROL system is used for the quality inspection of these parts. An optical micrometer at the machine entry checks the size of the sockets. Using different image processing systems, both front faces and the shoulder face are tested for breakouts, fissures etc. Sensor technology applied |

| __________________________________________________________________________________________________________ |

Diameter - radial/axial runout - measurement at disk motors The production of disk motors has to meet the highest mechanical accuracy requirements. In order to ensure perfect functioning of the disk drives the drive units are measured and evaluated with respect to diameter, true running, and axial running. Since production specifications of < 5 μm have to be measured under nominal speed, a decision has been made to use the fast and high-resolution capaNCDT system. In this measurement two sensors with measurement range50 μm that are adapted to the flange geometry are of special importance. Sensor technology applied |

| __________________________________________________________________________________________________________ |

Monitoring the commutator in electric motors The “eddyNCDT” system offers many advantages for the non-contact monitoring of the mechanical condition of the commutator in electric D.C. motors or generators. The system uses the eddy-current measuring principle, is not subject to wear and cannot affect or influence the commutator. Sensor technology applied |

| __________________________________________________________________________________________________________ |

Vibration displacement measurement in road tests With cars, tests on the running gears form the basic requirements for driving safety. Here sensors are needed which can also withstand the high demands of road tests. As an example, draw-wire sensors are mounted in parallel to the shock absorbers for the vibration displacement measurement and the data is recorded for varying road-surface quality. The displacement signal obtained is differentiated to give the vibration velocity and vibration acceleration. Sensor technology applied |

| __________________________________________________________________________________________________________ |

Co-planarity of IC-pins The term „co-planarity“ discribes the proper seating of the tips of fine-pitch device leads on the copper pads on a PCB prior to solder process. The coplanarity is a critical dimension for the quality of the soldered joints, because no reliable and correct soldering can be done if there is a gap between the lead and the pad. In state of the art automatic assembly machines the co-planarity of components is measured during the assembling process. The component to be measured is passed over a triangulation displacement sensor which has a laser beam that scans the row of pins. Sensor technology applied |

| __________________________________________________________________________________________________________ |

Deformation measurement on lightweight structures Specially designed measurement systems, which record the surface contours without reactive effects on the lightweight structures, are employed for the examination of component deformations under load. To achieve this, two laser-based optical displacement measurement systems can be mounted on a movable subframe subdivided with nineteen fixed reference points. Sensor technology applied |

| __________________________________________________________________________________________________________ |

Measurement of the radial deviation on superconducting magnets At the Institute for Solids and Materials Research (IWF) Dresden a motor with magnetic bearings has been developed using high temperature superconductors which can be employed for feed pumps for liquid nitrogen. The most important application of superconducting permanent magnets is the superconducting magnetic bearing. For the measurement of the radial deviation of these magnetic bearings, U1 eddy current sensors with special temperature compensation for -196 °C and 20 °C are used in the evacuated and cooled ambient. Sensor technology applied |

| __________________________________________________________________________________________________________ |

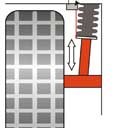

Measurement of the radial deviation of a cutter disk

Sensor technology applied |

| __________________________________________________________________________________________________________ |

Vibration test of wet razor Modern wet razors provide the function of supporting the shave using vibration. A functional test is performed at the end of production for these models. The razor is switched on and placed in the light band of the optoCONTROL optical micrometer. The laser micrometer measures the vibration amplitude and the frequency. Sensor technology applied

|

| __________________________________________________________________________________________________________ |

Non-contact measurement of relay contact movementEven the layman can detect wether a relay is energized or not. The question how on the other hand, is difficult to answer even for the expert. What he needs to know is the timing of certain specific parameters such as pick-up delay, armature play, armature displacement, armature bounce, contact displacement, final contact position and contact bounce. These parameters can be derived from the measured armature and contact movement. The relay characteristics must not be affected in any way by the measuring equipment in the event. The noncontact displacement measuring systems optoNCDT offer the ideal solution to this problem. Sensor technology applied |

| __________________________________________________________________________________________________________ |

Automatic inspection and repair of marine propellers Deformed ship propellers are bent back to their original condition using special machines. Previously, this work was performed manually but today it has been replaced by automatic systems. The current shape of the propeller is measured and stored using an optoNCDT 1700 series laser sensor. The system then automatically recognizes which positions need focusing on. In doing this, the laser sensor measures the shiny surface of the propeller, which it is able to do extremely well by using fast, real-time surface compensation (RTSC) exposure regulation. Sensor technology applied |

| __________________________________________________________________________________________________________ |

Examination of the oscillation behavior of toothed-belt camshaft drives To examine the influence of various system and operating parameters on the dynamic behavior of multi-disk drives a belt oscillation test bench has been set up which simulates the toothed-belt drive system of a direct injection motor vehicle diesel engine. The periodically fluctuating shaft torques generate rotary oscillations in the toothed-belt drive, which lead to transverse belt oscillation. Five laser optical position measuring systems are arranged closely side by side, so that oscillations of higher order can also be measured safely. Sensor technology applied |