|

|

||||||||

Laser sensors for metals and rough surfaces

|

||||||||

|

A small light spot diameter is not recommended for measurements on shiny metals or machined surfaces that show small micromachining marks. Micromechanical surface properties allow no homogeneous reflection which results in noisy or unstable measurement signals.

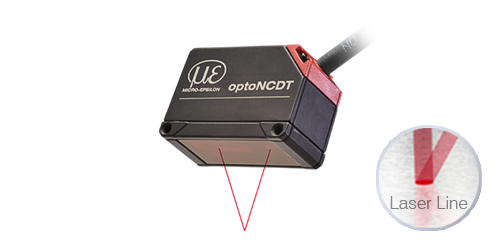

For these requirements, laser sensors with an oval light spot of only a few millimeters width, similar to a short »laser line«, are recommended. The oval light spot combined with special software algorithms filter out disturbances caused by surface roughness, defects, depressions or smallest holes. In addition, this type of sensor is suitable for distance measurements on structured surfaces, i.e. when the distance to the surface and not the structure of the surface is to be measured. The oval light spot is not influenced by surface structures and ensures constant and stable generation of measurement values. |

||||||||

Anti speckle laser sensor – optoNCDT 1750LL |

||||||||

|

||||||||

New: New: Smart laser sensor for shiny metallic objects – optoNCDT 1420LL |

||||||||

|

||||||||

Extreme dynamic laser sensor with anti speckle feature – optoNCDT 2300LL |

||||||||

|

||||||||

Measuring ranges (mm): 2 | 10 | 20 | 50

Measuring ranges (mm): 2 | 10 | 20 | 50