|

|

|

|

|

Automotive

As the complexity and precision of automotive parts become more demanding, the choice of sensor and the way that data is processed becomes more integral to the system and workstation design.

|

|

|

|

Alignment of camshaft bearings using Digital Miniature Probe fixture

Because they are quick, accurate, and cost effective, the Solartron Miniature Probe is frequently utilized in these types of bearing checks. It is small enough to be mounted to a bore gauge, and its double flexure design provides the ruggedness for the repeated up and down from being threaded through the mounts. Also, since the probes come pre-calibrated, they only need to be mounted and mastered before use, ensuring an easy setup on the factory floor.

|

Available Probes:

Mini Probe Mini Probe

Download Application Story:

|

|

|

|

Available Probes:

Single Leaf Flexure Single Leaf Flexure

Download Application Story:

|

Single Leaf Flexure for use in snap gauges for crankshafts

Solartron’s Single Leaf Flexure is for more abrasive applications, as well as jobs where standard pencil probes will not fit. It has been tested to over 20 million cycles, with extendable arms that can fit inside bores or other tough to reach places.

|

|

Wireless bore gauging for machine centres

Solartron’s WiGauge™ and WiGauge™ Gen II are built for bore and depth gauging applications where wired instruments are unfeasible or undesirable. A calibrated, digital 10 mm spring probe is encased in high impact ABS handle with an optional new integrated colour LCD screen.

|

Recommended Products

WiGauge™ WiGauge™

Download Application Story:

|

|

|

Recommended Products

WiGauge™ WiGauge™

Download Application Story:

|

Taking differential housing measurements using WiGauge™

Using one centralised WiGauge™ wireless solution for bore gauging on multi-machine cell projects, eliminates any redundancy that would occur by individually equipping each machine with its own independent ‘cabled’ system, ultimately dramatically reducing costs.

|

|

Cylinder head and cam shaft measurement using Flexures and Gauging Probes

With measurements being taken at 3 points per journal and cradle, both Gauging Probes and Flexures were used to achieve optimum results, with the diameter and centre point being calculated from these figures. In total, 12 Solartron sensors were used in the one fixture, communicating with one another using the Orbit® 3 Network, a fully formed digital measurement system.

|

Recommended Products

Digital Probe Digital Probe

Flexure Gauge Flexure Gauge

Download Application Story:

|

|

|

Recommended Products

Ultra Feather Touch Ultra Feather Touch

Download Application Story:

|

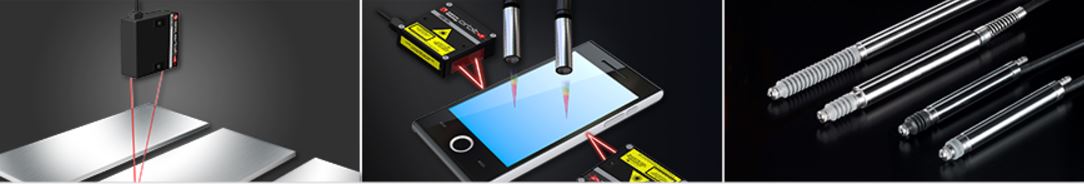

Glass gauging system

Taking measurements of glass for automotive and industrial applications needs to be precise and delicate. A combination of probes and non-contact sensors can be used with a single Orbit® Manager providing reliable data acquisition.

|

|

Measurements of automotive parts

As technologies have progressed, car manufacturers have had to ensure the precision production of parts and casing to ensure the smooth running and ultimate performance they strive to achieve, whilst keeping production costs down.

Using 120 probes integrated using the Orbit® Network, the interior geometry of the two main cases of a transfer/differential system could be measured at one time in an off-gauge station.

|

Recommended Products

Digital Probe Digital Probe

Flexure Gauge Flexure Gauge

Download Application Story:

|

|

|

Recommended Products

SI7500 SI7500

Download Application Story:

|

Piston gear measurement

Working alongside companies who supply accurate and reliable precision gauging probes to manufacturing companies, Solartron Metrology’s display unit can improve the overall product offering, providing data to the end user.

|

|

Cars mechanical prototyping process

When the mechanical engineers

are designing a new chassis or a new security device for the automotive market, they base their analysis on existing theoretical schematics and structures behaviors.

The validation processes are very important to match the theory and the reality. In studying the movement structure in real situation, they definitively settle it.

|

Recommended Products

S-Series S-Series

Download Application Story:

|

|

|

|

|

|

|

|

Product & Technology News

Orbit® Gauge Software

Application Selector

Download Catalogue

|