|

|

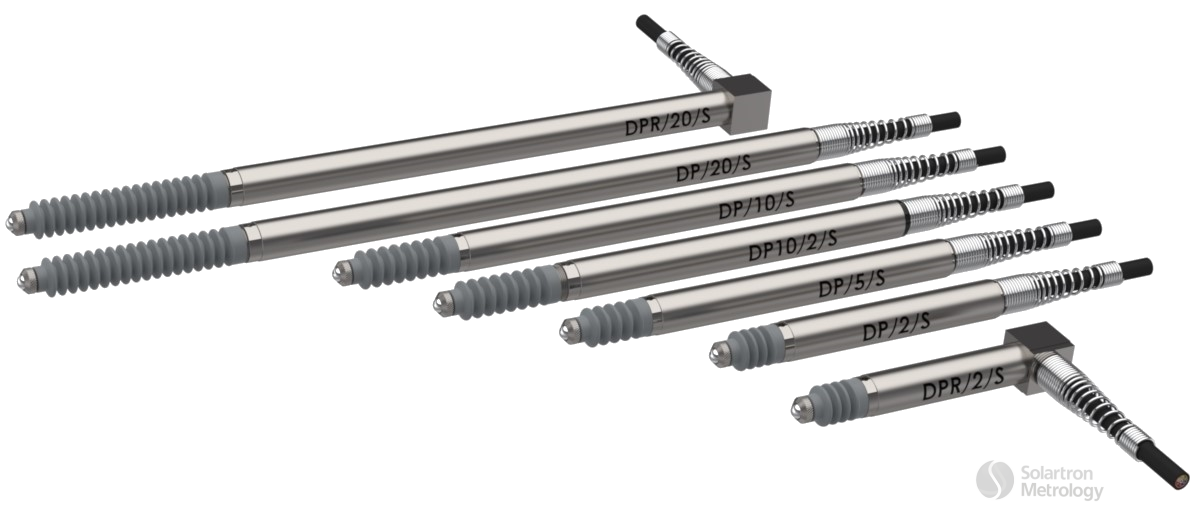

Standard Digital Displacement Sensors | Gauge Probes |

|

|

Digital Gauge Probes | Spring Push DP/S

|

|

Solartron Metrology contact digital gauging probes or displacement sensors provide the gauge builder with the most cost-effective solution for a range of dimensional precision measurement and positioning applications. The digital gauge probe combines the strong features of a conventional linear variable differential transformer (LVDT) with enhanced accuracy. The accuracy specified for the digital sensor is total accuracy unlike conventional LVDTs which specify linearity. Another benefit of the digital displacement sensor (Gauge probe) is the probe requires no set up or adjustment with conditioning electronics like a traditional LVDT because the digital displacement sensor provides a precision measurement straight out of the box. Combining multiple sensors using the Orbit Digital Measurement network is easy and data can be read using a Solartron readout or the Gauge Computer Software making system integration simple. Like a conventional LVDT the displacement probe tip is pushed out using an internal spring. The precision bearings inside the digital displacement senor ensure precise positioning of the contact senor tip. At the same time the unique bearing design provides repeatable measurements even when the displacement transducer is subjected to mechanical side loads. Attention to detail in both design and manufacture of the displacement sensor ensures precision measurement throughout the linear displacement transducer's life. Solartron Metrology offers a large range of displacement sensors to suit multiple applications with different cable outlets (radial or axial), multiple measuring ranges, different cable types like steel braided which provides additional protection for displacement sensors that are being used in harsh environments. |

|

|

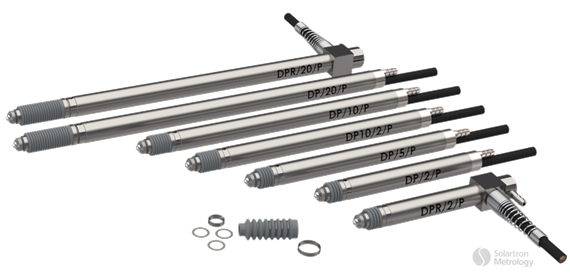

DP/P – Pneumatic Push Actuation

|

|

Solartron Metrology contact digital gauging probes or displacement sensors provide the gauge builder with the most cost-effective solution for a range of dimensional precision measurement and positioning applications. A pneumatic displacement sensor (gauge probe) allows the number of parts in the fixture to be reduced resulting in improved reliability and reduced fixture cost. It also allows for fast automatic loading of the part into the gauge as the displacement probe tip can be in the fully ‘retract position’ when this is occurring. The benefit of using a pneumatic push displacement sensor (gauge probe) compared to a spring push probe is that there is less need to design mechanisms to bring the contact senor tip onto the part being measured thus simplifying the overall gauge design. A pneumatic displacement sensor (gauge probe) allows the number of parts in the fixture to be reduced resulting in improved reliability and reduced fixture cost. It also allows for fast automatic loading of the part into the gauge as the displacement probe tip can be in the fully ‘retract position’ when this is occurring. The pneumatic digital gauge probe combines the strong features of a conventional linear variable differential transformer (LVDT) with enhanced accuracy. The accuracy specified for the digital senor is total accuracy unlike conventional LVDT’s which specify linearity. Another benefit of the digital displacement sensor (Gauge probe) is the probe requires no set up or adjustment with conditioning electronics like a traditional LVDT because the digital displacement senor provides a precision measurement straight out of the box. Combining multiple sensors using the Orbit Digital Measurement network is easy and data can be read using a Solartron readout or the Gauge Computer Software making system integration simple. Attention to detail in both design and manufacture of the displacement sensor ensures precision measurement throughout the linear displacement transducer's life. Solartron Metrology offers a large range of displacement sensors to suit multiple applications with different cable outlets (radial or axial), multiple measuring ranges, different cable types like steel braided which provides additional protection for displacement sensors that are being used in harsh environments. |

|

|

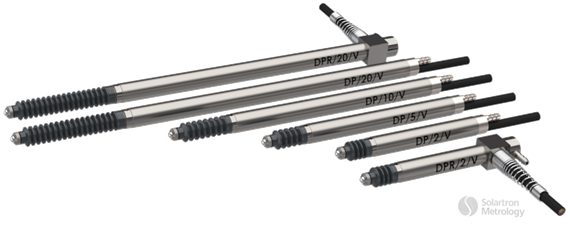

Digital Gauge Probe | Vacuum Retract DP/V

|

| The Vacuum retract displacement probes (gauge probes) offer an alternative means of controlling the contact sensor tip using a vacuum rather than a positive pneumatic pressure. In all other ways they perform the same as pneumatic displacement sensors (gauge probes) and like all the digital gauge probes have advantages other traditional LVDT sensors. |

|

|

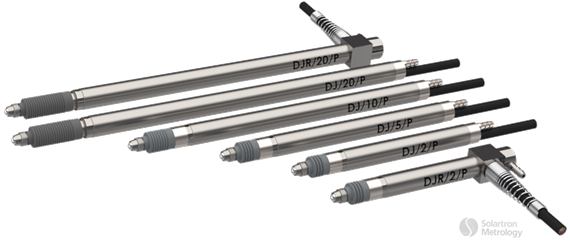

Digital Gauge Probe | Pneumatic Piston Push (Jet) DP/P

|

|

A pneumatic displacement sensor (gauge probe) allows the number of parts in the fixture to be reduced resulting in improved reliability and reduced fixture cost. It also allows for fast automatic loading of the part into the gauge as the displacement probe tip can be in the fully ‘retract position’ when this is occurring. The benefit of using a pneumatic push displacement sensor (gauge probe) compared to a spring push probe is that there is less need to design mechanisms to bring the contact senor tip onto the part being measured thus simplifying the overall gauge design. A pneumatic displacement sensor (gauge probe). allows the number of parts in the fixture to be reduced resulting in improved reliability and reduced fixture cost. It also allows for fast automatic loading of the part into the gauge as the displacement probe tip can be in the fully ‘retract position’ when this is occurring. One issue with pneumatic push displacement probes is that the air inflates the probe gaiter to push the contact sensor tip onto the part being measured. If the gaiter becomes damaged it may not inflate and therefore the probe cannot operate. The Pneumatic Piston Push (Jet) probe uses an internal piston so will continue to operate even if the gaiter is damaged. Air is bled out from a small hole near the front of the contact sensor to allow for retraction therefore the sealing (IP50) may not be suitable for all applications. The pneumatic piston push displacement probes (gauge probes) like all the digital gauge probes have advantages over traditional LVDT sensors. |

0.5,1,2,5,10,20 and 30 mm displacement transducer measuring ranges

0.5,1,2,5,10,20 and 30 mm displacement transducer measuring ranges