|

|

|

|

|

|

|

|

|

|

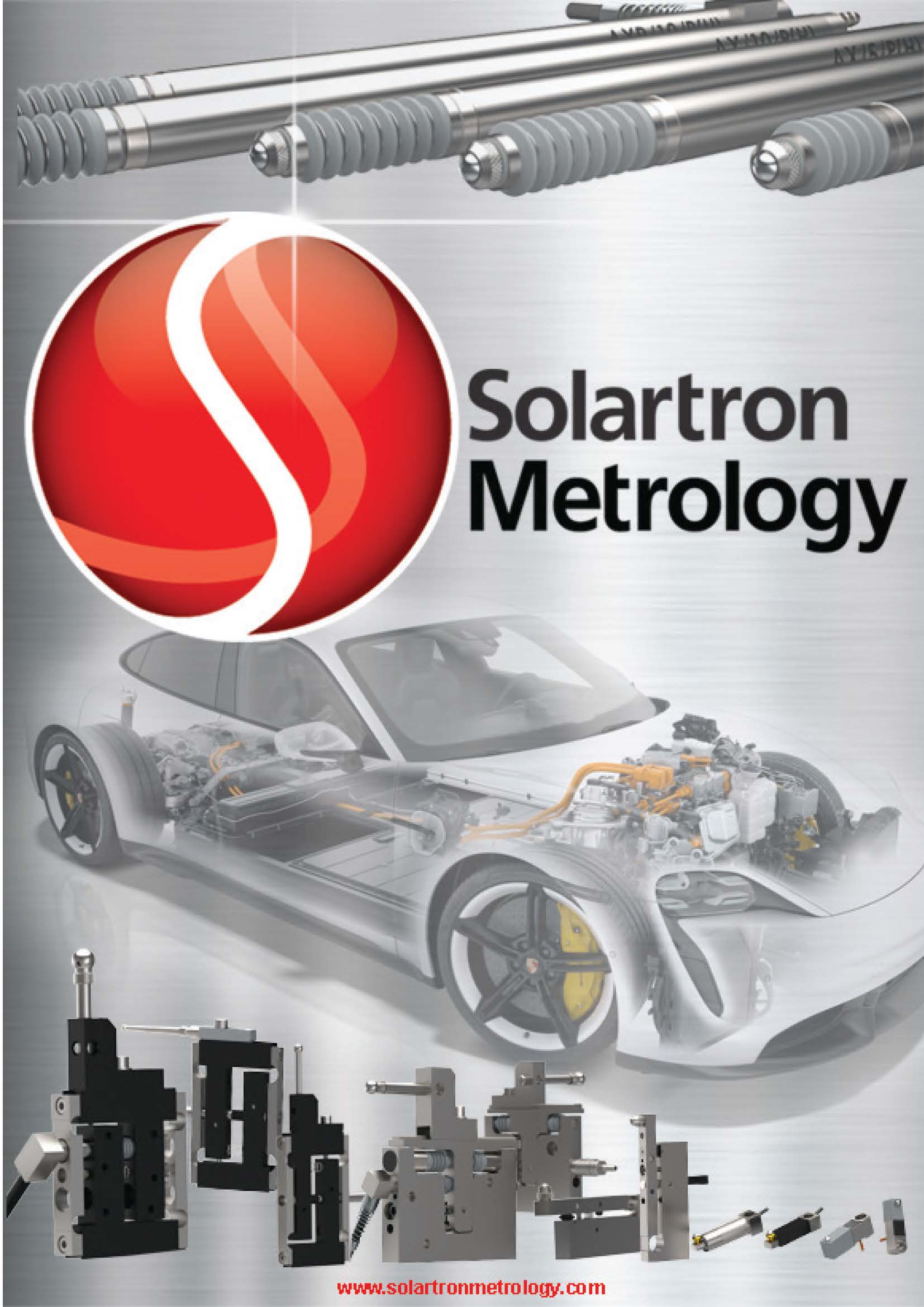

Spring, Pneumatic Push and Vacuum Retract Probes

Contact gauge probes often provide the most cost effective solution for a wide range of measuring and positioning applications.

In a conventional pencil probe the tip is pushed out using an internal spring. When installed in a fixture it is frequently required to design a mechanism to bring the probe into contact with the part being measured.

A pneumatic probe (either pneumatic push or vacuum retract) allows the number of parts in the fixture to be reduced resulting in improved reliability and reduced fixture cost. It also allows for fast automatic loading of the part into the gauge as the probe tip can be in the fully ‘retract position’ when this is occurring. Probes such as the AX/5/1 have a mechanical movement of 10 mm with a calibrated range of ±1 mm at the beginning of the movement.

|

|

|

|

|

-

Displacement transducer measuring ranges ±0.25, ± 0.5, ± 1, ± 1.5, ± 2,5, ± 5, ± 10 mm Displacement transducer measuring ranges ±0.25, ± 0.5, ± 1, ± 1.5, ± 2,5, ± 5, ± 10 mm

-

Linearity better than 0.5% of measurement Linearity better than 0.5% of measurement

-

Repeatability precision better than 0.05 µm Repeatability precision better than 0.05 µm

-

Range of contact sensor tips for different applications Range of contact sensor tips for different applications

-

Spring actuation Spring actuation

-

Standard contact sensor tip force of 0.7 N (options available) Standard contact sensor tip force of 0.7 N (options available)

-

IP65 sealing (fully sealed options available) IP65 sealing (fully sealed options available)

-

Inductive sensors with excellent side load capability Inductive sensors with excellent side load capability

-

Linear Variable Differential Transformer (LVDT) or Half Bridge options Linear Variable Differential Transformer (LVDT) or Half Bridge options

|

|

|

|

|

-

± 1, ± 2,5, ± 5, ± 10 mm displacement transducer measuring ranges ± 1, ± 2,5, ± 5, ± 10 mm displacement transducer measuring ranges

-

Linearity better than 0.5% of precision measurement Linearity better than 0.5% of precision measurement

-

Repeatability precision better than 0.05 µm Repeatability precision better than 0.05 µm

-

Range of contact sensor tips available Range of contact sensor tips available

-

Pneumatic actuation Pneumatic actuation

-

Standard contact sensor tip force of 0.7N (options available) Standard contact sensor tip force of 0.7N (options available)

-

IP65 sealing (fully sealed options available) IP65 sealing (fully sealed options available)

-

Inductive sensors with excellent sideload capability Inductive sensors with excellent sideload capability

-

Linear Variable Differential Transformer (LVDT) or Half Bridge options Linear Variable Differential Transformer (LVDT) or Half Bridge options

-

Displacement sensors available with vacuum retract Displacement sensors available with vacuum retract

|

|

|

|

|

-

± 1, ± 2,5, ± 5, ± 10 mm displacement transducer measuring ranges ± 1, ± 2,5, ± 5, ± 10 mm displacement transducer measuring ranges

-

Linearity better than 0.5% of precision measurement Linearity better than 0.5% of precision measurement

-

Repeatability precision better than 0.05 µm Repeatability precision better than 0.05 µm

-

Range of contact sensor tips available Range of contact sensor tips available

-

Pneumatic actuation using piston - still operates if gaiter damaged Pneumatic actuation using piston - still operates if gaiter damaged

-

Standard contact sensor tip force of 0.7N (options available) Standard contact sensor tip force of 0.7N (options available)

-

IP50 sealing (fully sealed options available) IP50 sealing (fully sealed options available)

-

Inductive sensors with excellent sideload capability Inductive sensors with excellent sideload capability

-

Linear Variable Differential Transformer (LVDT) or Half Bridge options Linear Variable Differential Transformer (LVDT) or Half Bridge options

|

|

|

|

|

|

|

Product & Technology News

Orbit® Gauge Software

Application Selector

Download Catalogue

|

Displacement transducer measuring ranges ±0.25, ± 0.5, ± 1, ± 1.5, ± 2,5, ± 5, ± 10 mm

Displacement transducer measuring ranges ±0.25, ± 0.5, ± 1, ± 1.5, ± 2,5, ± 5, ± 10 mm